Wastewater treatment system and wastewater treatment process

A wastewater treatment system and wastewater treatment technology, applied in the field of water treatment, can solve problems such as river water quality not up to standard, achieve the effects of reducing adverse impacts, overcoming inhomogeneity, and stabilizing effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

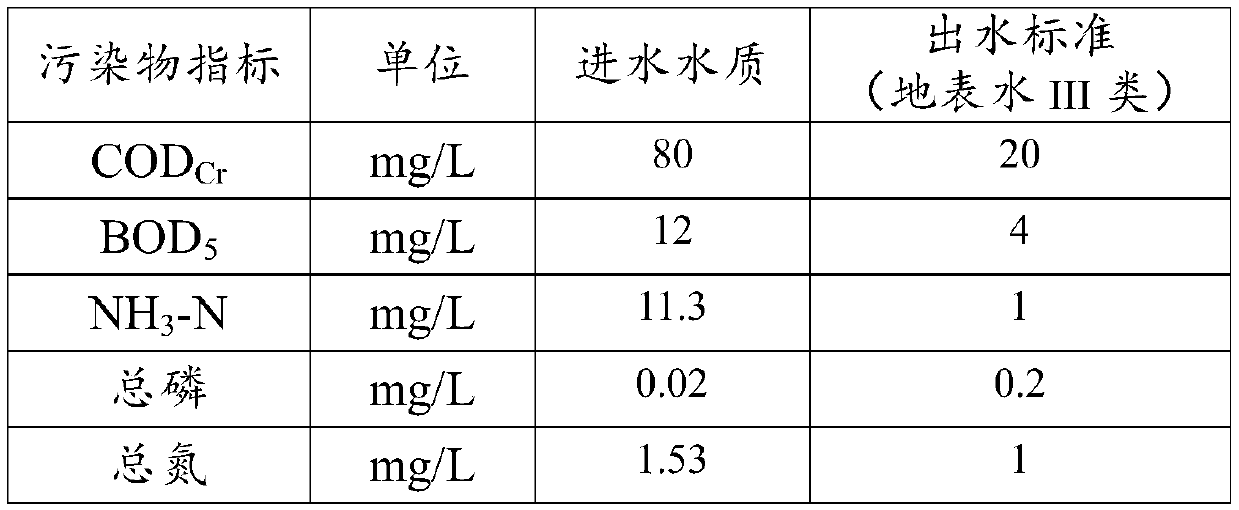

[0090] Tail water treatment project of a paper mill in Southwest China, with a discharge volume of 3500m 3 / d. Table 1 shows the main design indicators of the designed influent and effluent water quality of this project.

[0091] Table 1 Design inlet and outlet water quality

[0092]

[0093] Homogeneous tank design: L*B*H (length*width*height) = 14m*2m*5.5m.

[0094] Ozone contact oxidation pool design: 1) Ozone generators are 500g / h (A area) 300g / h (B area); 2) Contact time 20min; 3) Effective water depth 5m; 4) Contact oxidation pool size: L*B *H=3m*2m*5.5m (B area); L*B*H=4m*2m*5.5m (A area). The biological contact oxidation tank is equipped with 3 expansion chambers, and the microporous aeration head is used to release ozonated gas. The cover plate is set on the top of the tank to seal the contact tank, and an exhaust gas recovery device is installed to avoid leakage.

[0095] Design of comprehensive pretreatment tank: 1) Hydraulic retention time: 4h; 2) Effective ...

Embodiment 2

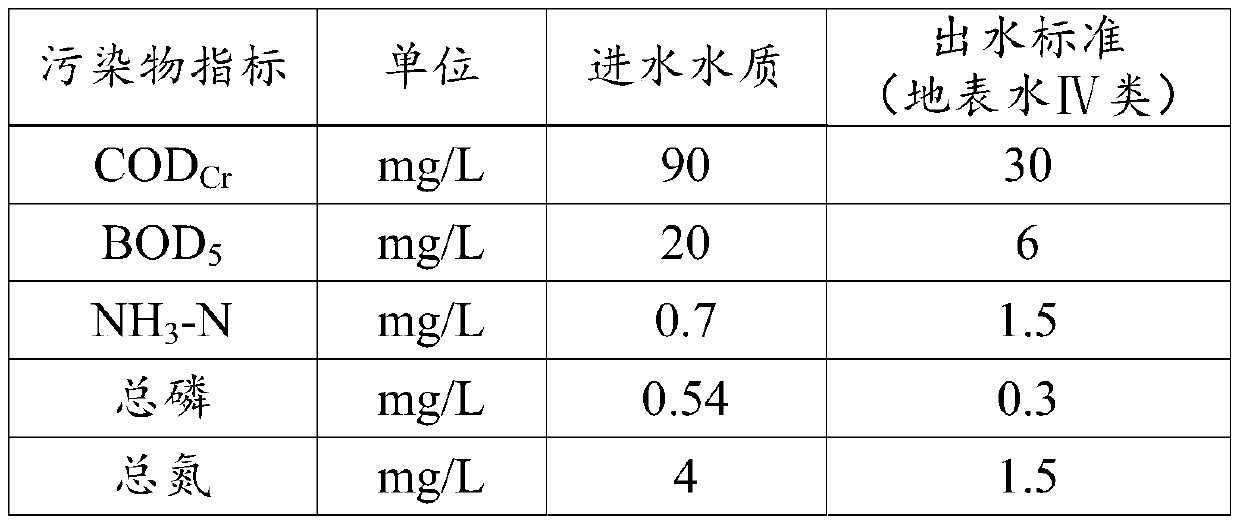

[0100] Tail water treatment project of a paper mill in central China, with a discharge volume of 7000m 3 / d. Table 2 shows the main design indicators of the design influent and effluent water quality of this project.

[0101] Table 2 Design inlet and outlet water quality

[0102]

[0103] Homogeneous tank design: L*B*H=26m*2m*5.5m.

[0104] Ozone contact oxidation tank design: 1) The ozone generators are 800g / h (A zone) and 500g / h (B zone); 2) The contact time is 20min; 3) The effective water depth is 5m; 4) The size of the contact oxidation tank: L*B *H=5m*2m*5.5m (B area); L*B*H=8m*2m*5.5m (A area).

[0105] Design of comprehensive pretreatment tank: 1) Hydraulic retention time: 4h; 2) Effective water depth of comprehensive pretreatment tank: H=5m; 3) Biofilm carrier layout density: 0.1m 2 / m 3 ;4) Size of comprehensive pretreatment pool: L*B*H=14m*6m*5.5m (B area); L*B*H=16m*8m*5.5m (A area); 5) Artificial aquatic plant carrier: 840m (A district); 1480m (B district...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com