High-efficiency environmental-friendly polyvinyl chloride (PVC) lubricating agent and preparation method thereof

A PVC lubricant and lubricant technology, applied in the field of plastic products, can solve the problems of unfavorable process simplification and production of fine chemical enterprises, limit the use of PVC in the field, and reduce the mechanical properties of materials, so as to improve the workplace environment and improve the external lubrication effect , Reduce the effect of electrostatic damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

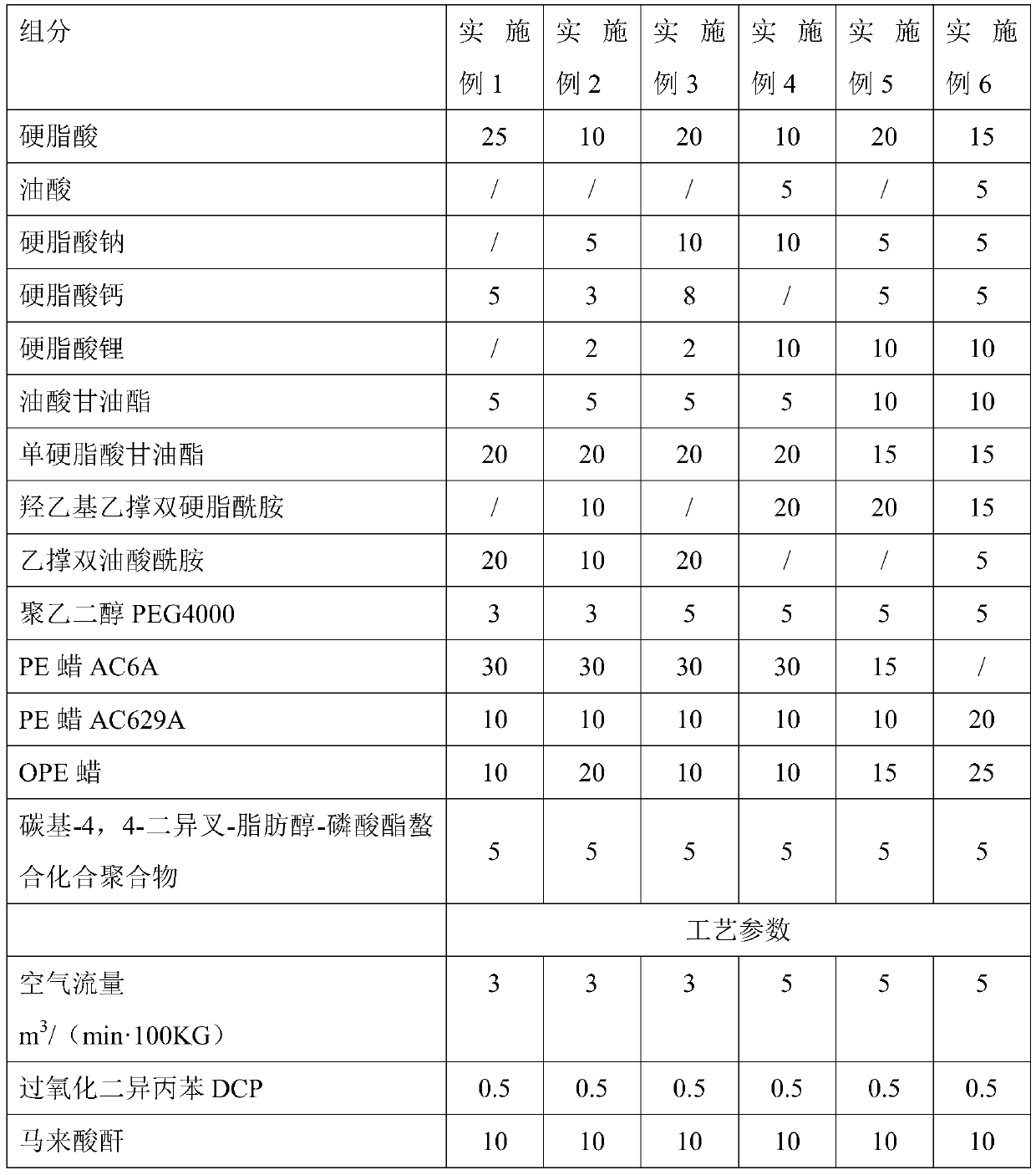

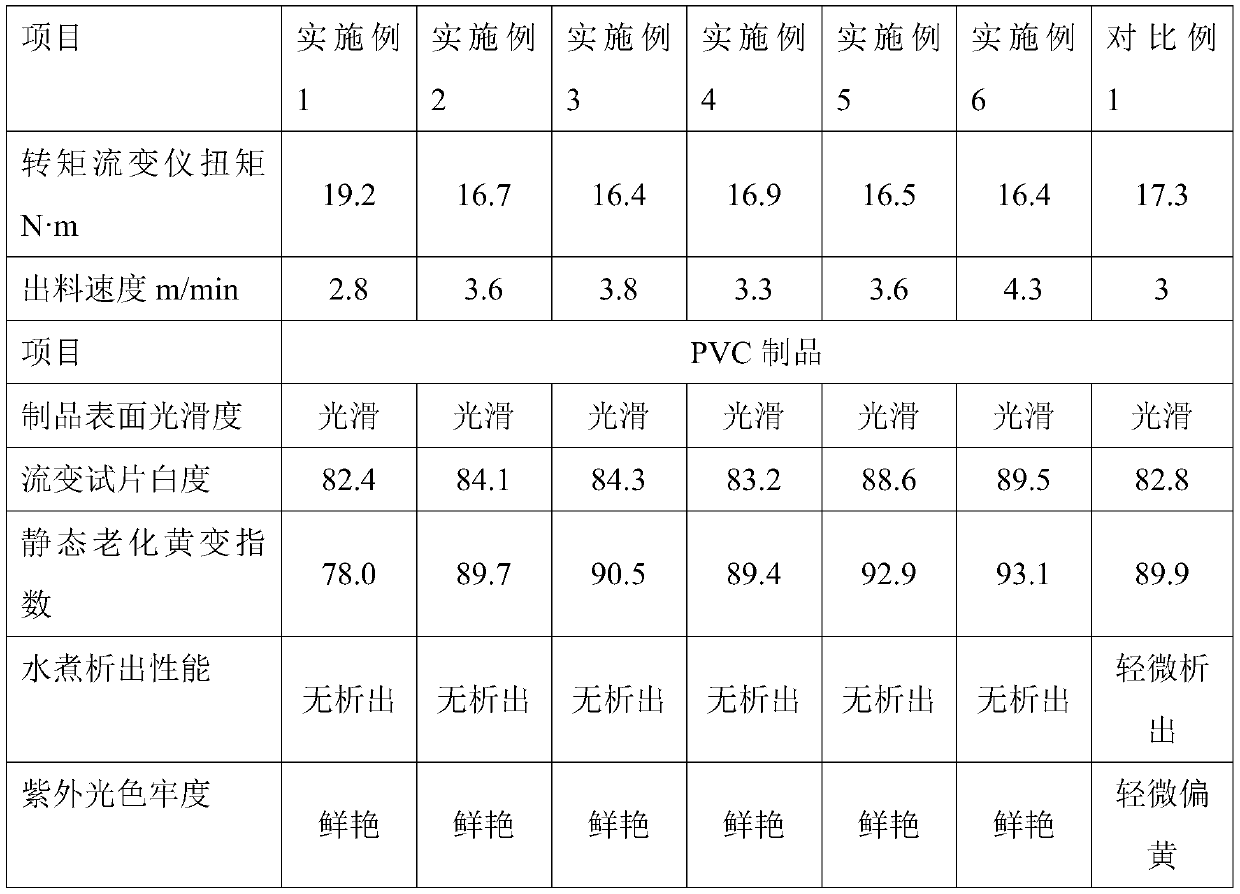

Embodiment 1-6

[0030] A kind of preparation method of efficient environment-friendly PVC lubricant, this method step is:

[0031] Mix the components shown in Table 1 in proportion and mix them evenly with a mixer to obtain a semi-finished compound powder PVC lubricant, then add the mixed semi-finished product to the enamel reaction kettle, raise the temperature to 140-160°C, and wait until the material is completely melted 3-5m per 100kg of semi-finished products 3 / min of air is used for high-temperature oxidation treatment of the semi-finished product to improve the polarity and compatibility of the mixed components, and it is kept at 140-160°C for 1-1.5 hours under the condition of air ventilation;

[0032] After oxidation, add peroxide crosslinking agent and maleic anhydride, continue to stir and keep warm at 150-170°C for 0.5 hours to complete the grafting reaction of mixed components; among them, add peroxide crosslinking agent 0.4kg per 100kg semi-finished product 10kg of maleic anhy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com