A metal organic framework corrosion inhibitor hydrogel composite material and its preparation method and application

A metal-organic framework and corrosion-inhibitor technology, applied in the field of metal-organic framework corrosion inhibitor hydrogel composite materials and their preparation, can solve problems such as inability to recycle and reuse, and achieve excellent corrosion detection, high identification and high Selective, destructive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

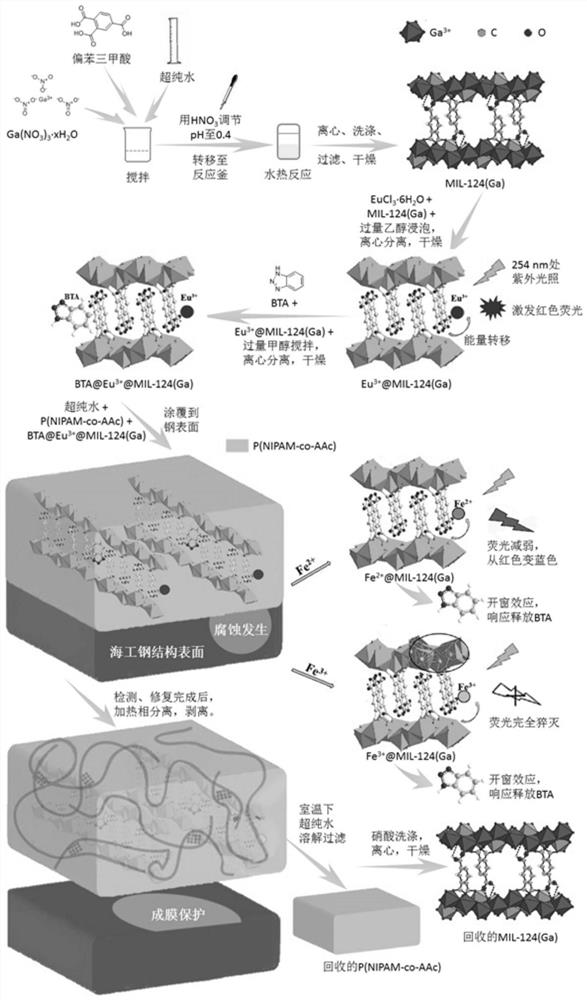

[0035] Example 1 Europium ion functionalized gallium-based metal-organic framework material Eu 3+ Preparation of @MIL-124(Ga)

[0036] Synthetic Eu 3+ @MIL-124(Ga), its chemical reaction equation is as follows:

[0037] 2Ga(NO 3 ) 3 +4H 2 O+C 9 h 6 o 6 = Ga 2 (OH) 4 (C 9 o 6 h 4 )+6HNO 3 (1)

[0038] Eu 3+ +3Ga 2 (OH) 4 (C 9 o 6 h 4 ) = [Eu 3+ ][Ga 2 (OH) 4 (C 9 o 6 h 4 )] 3 (2)

[0039] 1. First, 1.2g Ga(NO 3 ) 3 ·xH 2 O, 0.74g of trimellitic acid (molar ratio of 4:3) was mixed with 10mL of ultrapure water and stirred for 30min to obtain mixture A. The mixture A was transferred to a Teflon-lined hydrothermal synthesis reactor, and the mixture B was obtained after heating at 210°C for 24 hours. The initial pH values before and after heating were 0.4 and 0.6, respectively. The mixture B was centrifuged at 13,000 rpm for 5 min to obtain a white solid powder, which was washed three times with ultrapure water and dried at 100° C. for 24 h to obt...

Embodiment 2

[0044] 1. Based on Eu 3+ Preparation of Corrosion Inhibitor Hydrogel Composite with Functionalized Ga-MOF Encapsulated BTA

[0045] Step 1: Preparation of BTA@Eu 3+ @MIL-124(Ga)

[0046] Get the Eu prepared by the above-mentioned embodiment of 0.12g 3+ @MIL-124(Ga) and 0.013g phenylacryltriazole (BTA), stirred in 15mL methanol solution for 12h, then centrifuged at 5500rpm for 20min, dried in vacuum at 100°C for 6h, to obtain BTA-loaded metal Organic framework material BTA@Eu 3+ @MIL-124(Ga).

[0047] Step 2: Preparation of BTA@Eu 3+@MIL-124(Ga) Corrosion Inhibitor Hydrogel Composite.

[0048] Add 2.26g of isopropylacrylamide, 0.154g of N,N'-methylenebisacrylamide and 0.289g of acrylic acid into 100mL of ultrapure water, heat to 70°C under nitrogen protection, and stir at 600rpm. After 1 hour, dissolve 1.5 mg of potassium persulfate in 1 mL of ultrapure water and add it dropwise to the mixed solution, resulting in turbidity. Heating was stopped after 4h, and the mixture...

Embodiment 3~12

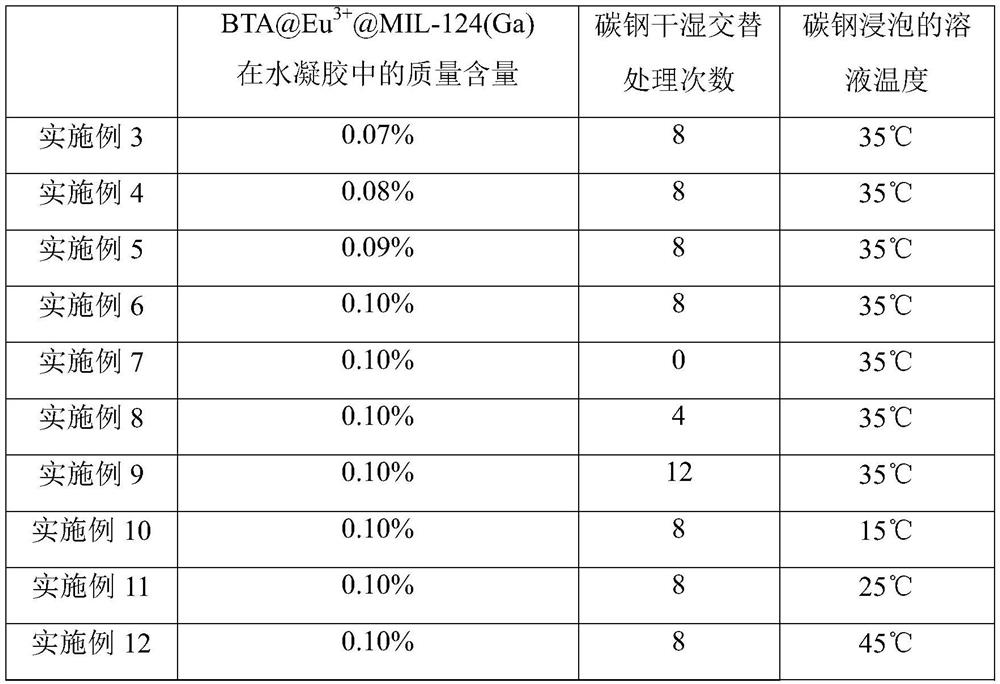

[0053] According to the preparation process of the corrosion inhibitor hydrogel composite described in Example 2, and according to the recorded use range of raw materials, the amount of raw materials can be adjusted to obtain loaded BTA@Eu 3+ @MIL-124(Ga) with different amounts of corrosion inhibitor hydrogel compound, change the number of dry and wet alternate treatments of carbon steel (that is, before coating the corrosion inhibitor hydrogel compound, carbon steel should be treated at 3.5% Submerged in the sodium chloride solution for 8h, then took out and dried for 16h at a humidity of 50% and a temperature of 25°C, a treatment cycle was 24h), and the temperature of the sodium chloride solution soaked in carbon steel carried out the design of the embodiment (see Table 1).

[0054] The condition design of table 1 embodiment 3~12

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com