Preparation method of micro-well structure SPRi chip and product and application thereof

A micro-well and chip technology, which is applied in the field of micro-well structure SPRi chip preparation, can solve the problems of complicated Jindao array chip processing procedures, limited detection throughput, and high cost, and achieve high-efficiency SPRi multi-component detection and parallel analysis, Easy extraction and analysis, high contrast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

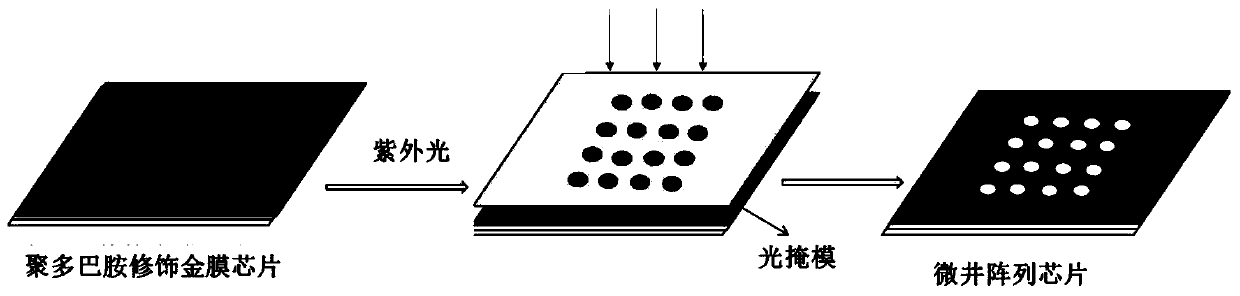

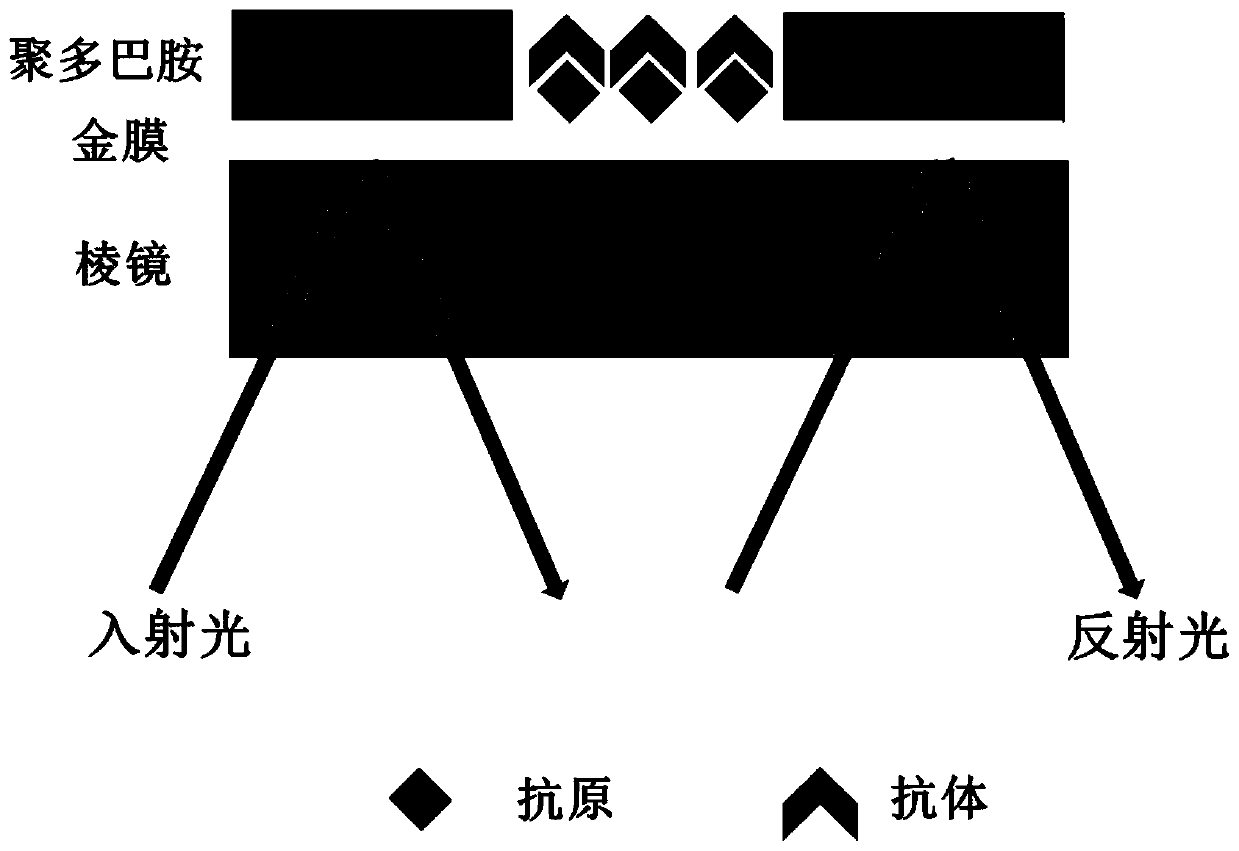

[0042] Prepare the microwell structure SPRi chip, the preparation process is as follows figure 1 As shown, the preparation method is as follows:

[0043] (1) choose the continuous flat gold film composition chip that is covered in the thickness 45nm of optical glass surface to be the gold film chip;

[0044] (2) Immerse the above-mentioned clean gold film chip in trihydroxy-methylaminomethane hydrochloride buffer solution containing polydopamine and pH=8.5 (wherein the volume mass concentration of polydopamine is 2 mg / mL), and take out the chip from the solution , washed with secondary water, blown dry with nitrogen;

[0045] (3) repeat the operation of step (2) with the gold film that above-mentioned nitrogen blows dry, make the polydopamine film thickness on the gold film chip reach 15nm, obtain the continuous gold film chip of polydopamine modification;

[0046](4) Place a photomask on the prepared polydopamine-modified continuous gold film chip, in the ultraviolet cleani...

Embodiment 2

[0048] Prepare microwell structure SPRi chip, its preparation method is as follows:

[0049] (1) choose to have the continuous smooth gold film composition chip that is covered in the thickness 50nm of optical glass surface to be gold film chip;

[0050] (2) Immerse the above-mentioned clean gold film chip in trihydroxy-methylaminomethane hydrochloride buffer solution containing polydopamine and pH=8.5 (wherein the volume mass concentration of polydopamine is 2 mg / mL), and take out the chip from the solution , washed with secondary water, blown dry with nitrogen;

[0051] (3) repeat the operation of step (2) with the gold film that above-mentioned nitrogen blows dry, make the polydopamine film thickness on the gold film chip reach 100nm, obtain the continuous gold film chip of polydopamine modification;

[0052] (4) Place a photomask on the prepared polydopamine-modified continuous gold film chip, in the ultraviolet cleaning instrument with Hg-Xel light source, set power 110W...

Embodiment 3

[0054] Prepare microwell structure SPRi chip, its preparation method is as follows:

[0055] (1) choose the continuous flat gold film composition chip that is covered in the thickness 55nm of optical glass surface to be the gold film chip;

[0056] (2) Immerse the above-mentioned clean gold film chip in trihydroxy-methylaminomethane hydrochloride buffer solution containing polydopamine and pH=8.5 (wherein the volume mass concentration of polydopamine is 2 mg / mL), and take out the chip from the solution , washed with secondary water, blown dry with nitrogen;

[0057] (3) repeat the operation of step (2) with the gold film that above-mentioned nitrogen blows dry, make the polydopamine film thickness on the gold film chip reach 60nm, obtain the continuous gold film chip of polydopamine modification;

[0058] (4) Place a photomask on the prepared polydopamine-modified continuous gold film chip, in the ultraviolet cleaning instrument with Hg-Xel light source, set the power 110W, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com