A method, an arrangement and use of an arrangement for olefin polymerisation

A technology of olefin polymerization and olefin, which is applied in the field of olefin polymerization, can solve problems not related to the use of improving the heat transfer rate of polymer particles, and achieve the effect of improving fluid dynamic conditions and being easy to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

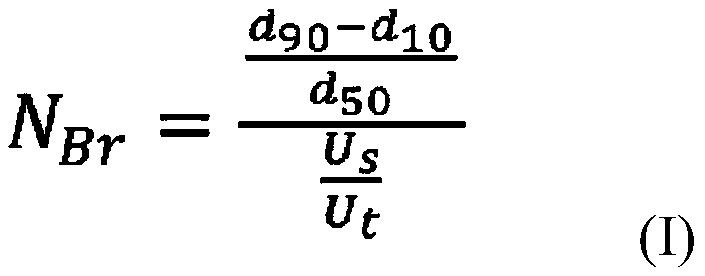

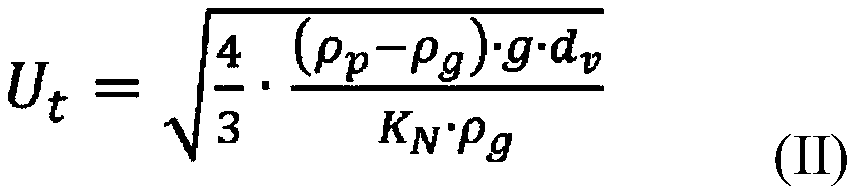

[0127] In a continuous polyethylene prepolymerization reactor, at a temperature of 70°C and a pressure of 65 bar, propane is used as a solvent (2300kg / h), an ethylene feed rate of 350Kg / h, 0.1KgH2 / tnC3, 40KgC4 / tnC3, Polymerized Ziegler-Natta catalyst particles with a particle size distribution of d 10 Equal to 10μm, d 50 Equal to 25μm, d 90 Equal to 40μm (that is, the span is 1.0), the average residence time is 30 minutes, and the average measured catalyst activity is 2Kg / gcat / h. Subsequently, the polymer material was transferred to a slurry loop reactor where the polymerization was carried out at a temperature of 85°C and a pressure of 63 bar, where the ratio of hydrogen to ethylene (expressed as mol / kmol) was 300 ( H2 / C2=300), the ratio of 1-butene to ethylene (expressed as mol / kmol) is 600 (C4 / C2=600), the solid concentration in the slurry phase loop reactor is 37% by weight, and the average residence time For 60 minutes, the average measured catalyst activity is 18Kg / gcat / h...

Embodiment 2

[0131] Example 1 was repeated, except for the operating conditions in the traditional bubbled fluidized gas phase reactor (GPR). Therefore, the polymerization was carried out at a temperature of 85°C and a total pressure of 19 bar. An ethylene partial pressure of 4.5 bar was used and 1-butene was added (copolymerization conditions). The ratio of hydrogen to ethylene (expressed as mol / kmol) is 8 (H2 / C2=8), and the ratio of 1-butene to ethylene (expressed as mol / kmol) is 650 (C4 / C2=650). The polymer particles were polymerized in GPR, the average residence time was 2 hours, and the average measured catalyst activity was 18Kg / gcat / h. Measure the d of the polymer particles prepared in the gas phase reactor 90 Equal to 2350μm. During the dynamic operation of the reactor, part of the temperature measurement value increased by 15°C beyond the temperature set value (ie 85°C), facing serious operation problems and detecting a large number of agglomerates.

[0132] Table 2. Aggregate hea...

Embodiment 3

[0134] Example 3 (invention):

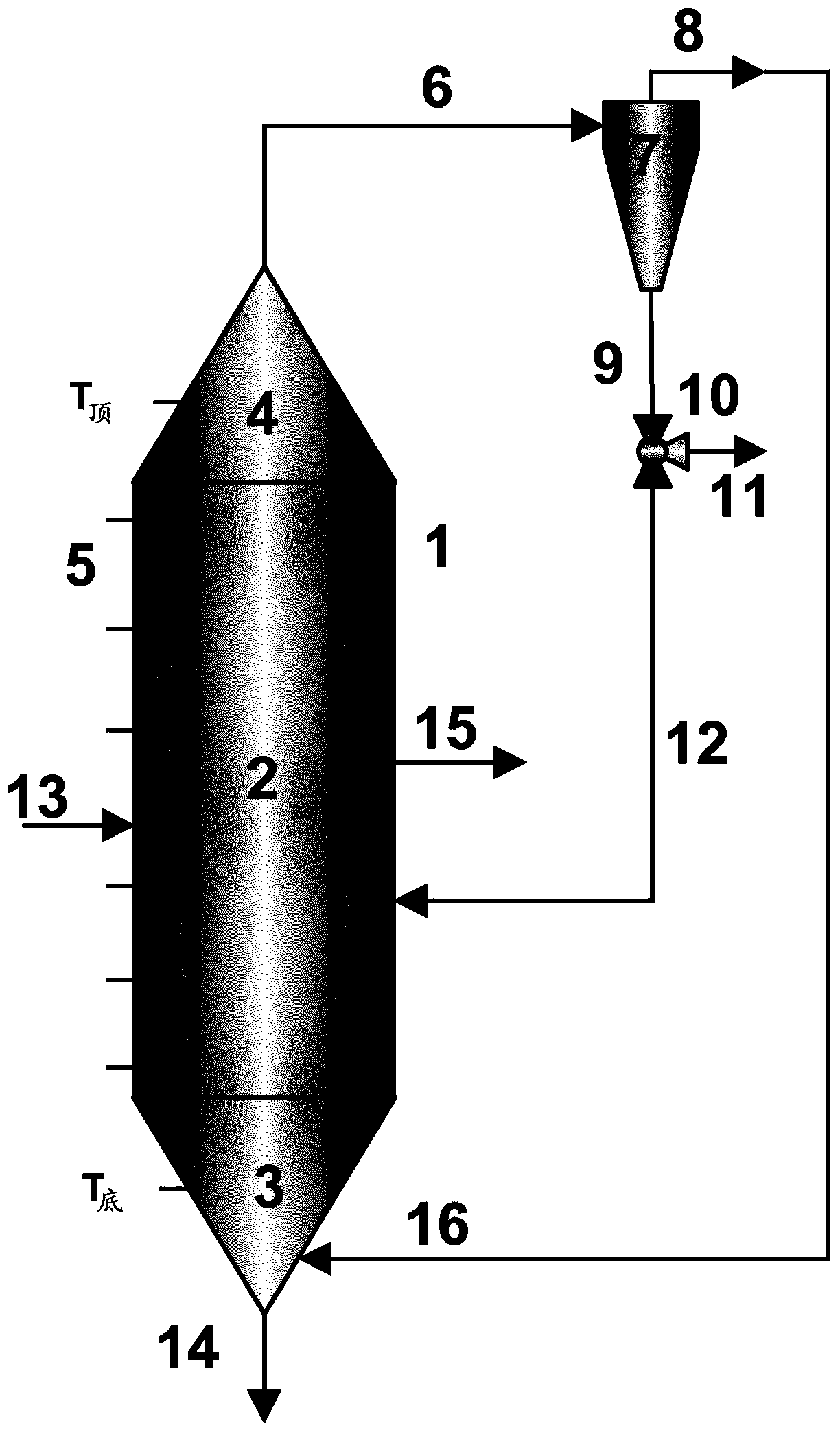

[0135] Example 2 is repeated, except that: after the flashing step, the polymer particles are fed into a gas phase reactor, which has a conical bottom and top area and no distribution plate, its inner diameter is 3.6m, and it is round The height of the cylindrical part is 16m. The apparent gas velocity is equal to 0.7m / s, the polymer particles are polymerized, the average residence time is 1.5 hours, and the average measured catalyst activity is 18Kg / gcat / h. Measure the d of the polymer particles produced in the gas phase reactor 90 It is 1850μm. During the dynamic operation of the reactor, no temperature measurement value in the reactor rises above the temperature set value (ie 85°C) by more than 6°C. No operational problems were observed and no large agglomerates were detected.

[0136] Table 3. Aggregate health status summary

[0137]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com