A kind of corrosion inhibitor and its application in copper metal pickling solution and chemical polishing solution

A chemical polishing and corrosion inhibitor technology, which is applied in the field of printed circuits, can solve the problems of high toxicity of nitrogen oxide gas, high cost of benzotriazole, and short service life of polishing agent, and achieves low cost and corrosion inhibition performance. Stable, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

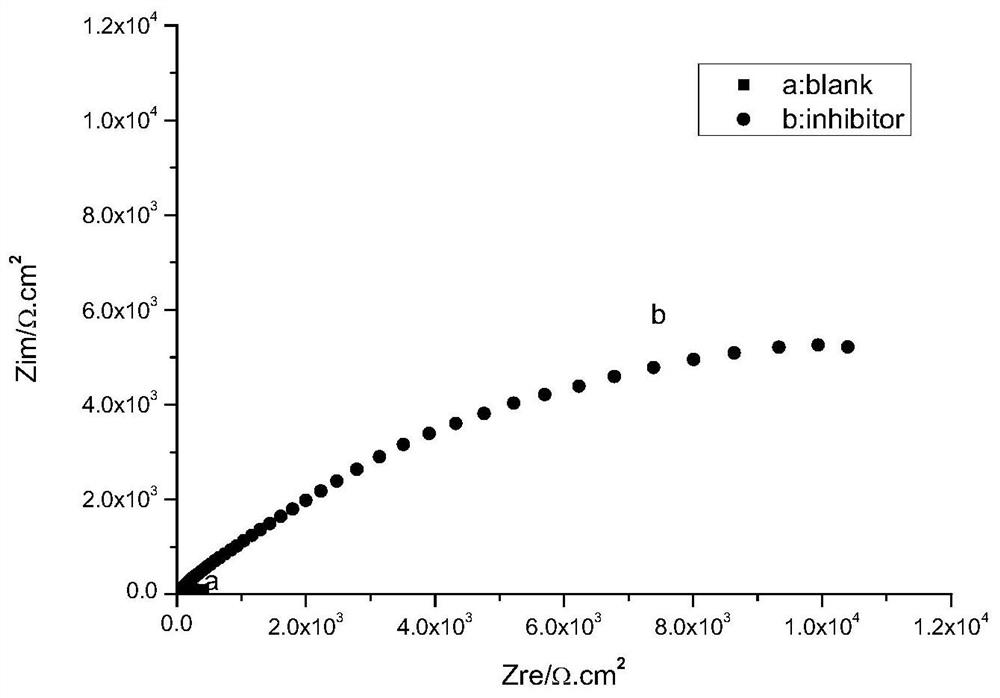

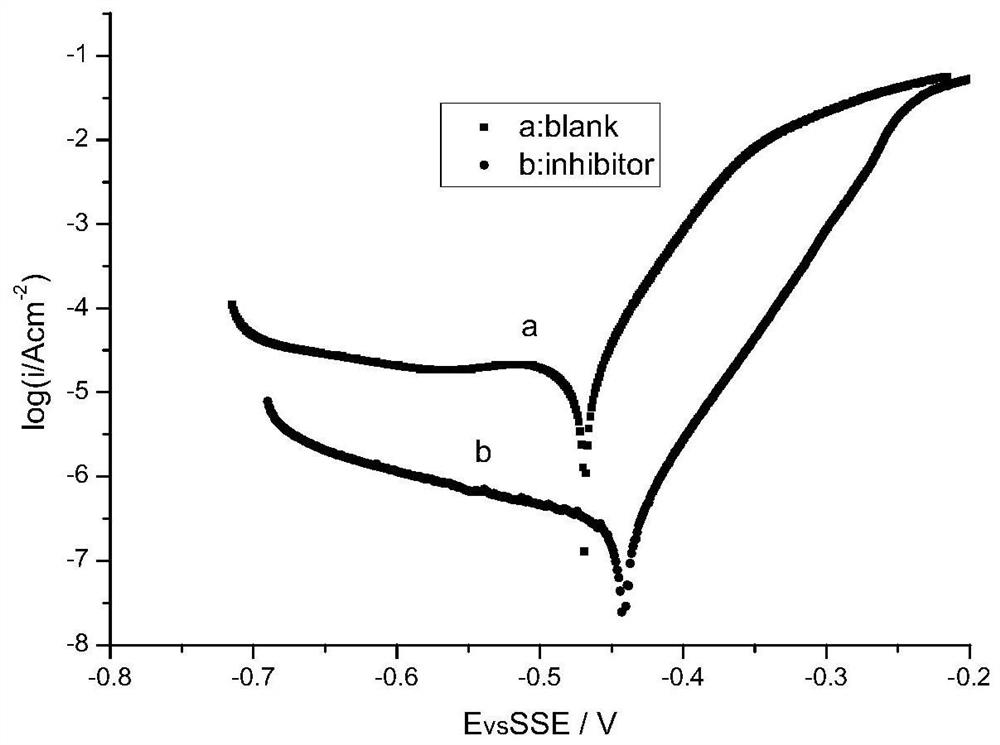

[0034] The present embodiment provides a copper metal pickling solution: the acid solution is dilute sulfuric acid: the concentration is 0.5mol / L, the acid solution consumption is 1L, and prothioconazole 10 -4 mol / L, the electrochemical test was carried out after immersing the cleaned and dried red copper in the acid treatment solution for 40 minutes at 25°C.

[0035] The results of electrochemical impedance spectroscopy test show that the corrosion inhibition efficiency is 96.1%, such as figure 1 Shown; Potentiodynamic polarization curve test results show that the corrosion inhibition efficiency is 98.7%, such as figure 2 Shown; The corrosion inhibitor in the acid treatment solution is shown to be an efficient corrosion inhibitor.

Embodiment 2

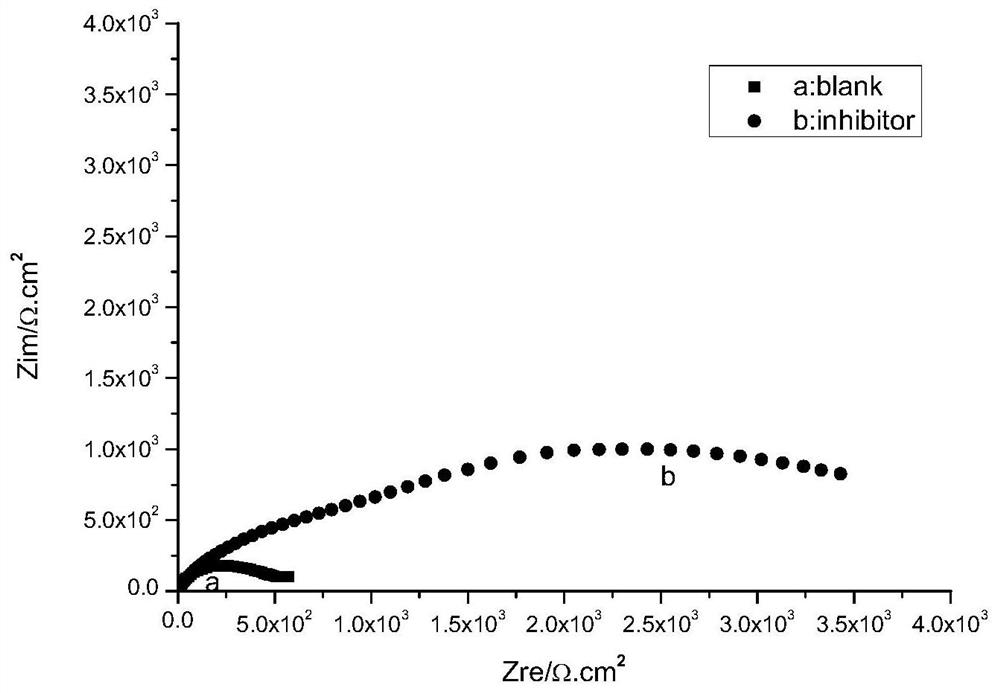

[0037] This embodiment provides a copper metal pickling solution: the acid solution is dilute sulfuric acid: the concentration is 0.5mol / L, the acid solution consumption is 1L, and 5-mercapto-1-methyltetrazole 10 -5mol / L, the electrochemical test was carried out after immersing the cleaned and dried red copper in the acid treatment solution for 40 minutes at 35°C.

[0038] Electrochemical impedance spectroscopy test results show that the corrosion inhibition efficiency is 83.5%, such as image 3 Shown; Potentiodynamic polarization curve test results show that the corrosion inhibition efficiency is 84.7%, as Figure 4 Shown; The corrosion inhibitor in the acid treatment solution is shown to be an efficient corrosion inhibitor.

Embodiment 3

[0040] This embodiment provides a copper metal pickling solution: the acid solution is dilute sulfuric acid: the concentration is 0.5mol / L, dilute nitric acid: 0.3mol / L, the amount of pickling solution is 2L, and prothioconazole 10 -4 mol / L, 5-mercapto-1-methyltetrazole 10 -4 mol / L, the electrochemical test was carried out after immersing the cleaned and dried red copper electrode in the acid treatment solution for 30 minutes at 45°C.

[0041] The highest corrosion inhibition efficiency obtained by the weight loss test is 91.4%, and the electrochemical impedance spectroscopy test results show that the corrosion inhibition efficiency is 89.9%, such as Figure 5 Shown; Potentiodynamic polarization curve test results show that the corrosion inhibition efficiency is 97.4%, such as Figure 6 Shown; The corrosion inhibitor in the pickling solution is shown to be an efficient corrosion inhibitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com