Waterproof and oilproof non-woven fabric and preparation process thereof

A technology of waterproof and oil-proof, production process, applied in the direction of sustainable manufacturing/processing, textile/flexible product manufacturing, non-woven fabrics, etc., can solve the problem of poor waterproof and oil-proof performance of waterproof and oil-proof non-woven fabrics Poor cloth elasticity, easy to lose waterproof and oil-proof performance, etc., achieve good waterproof and oil-proof effect, save manpower and equipment costs, and have good waterproof and oil-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

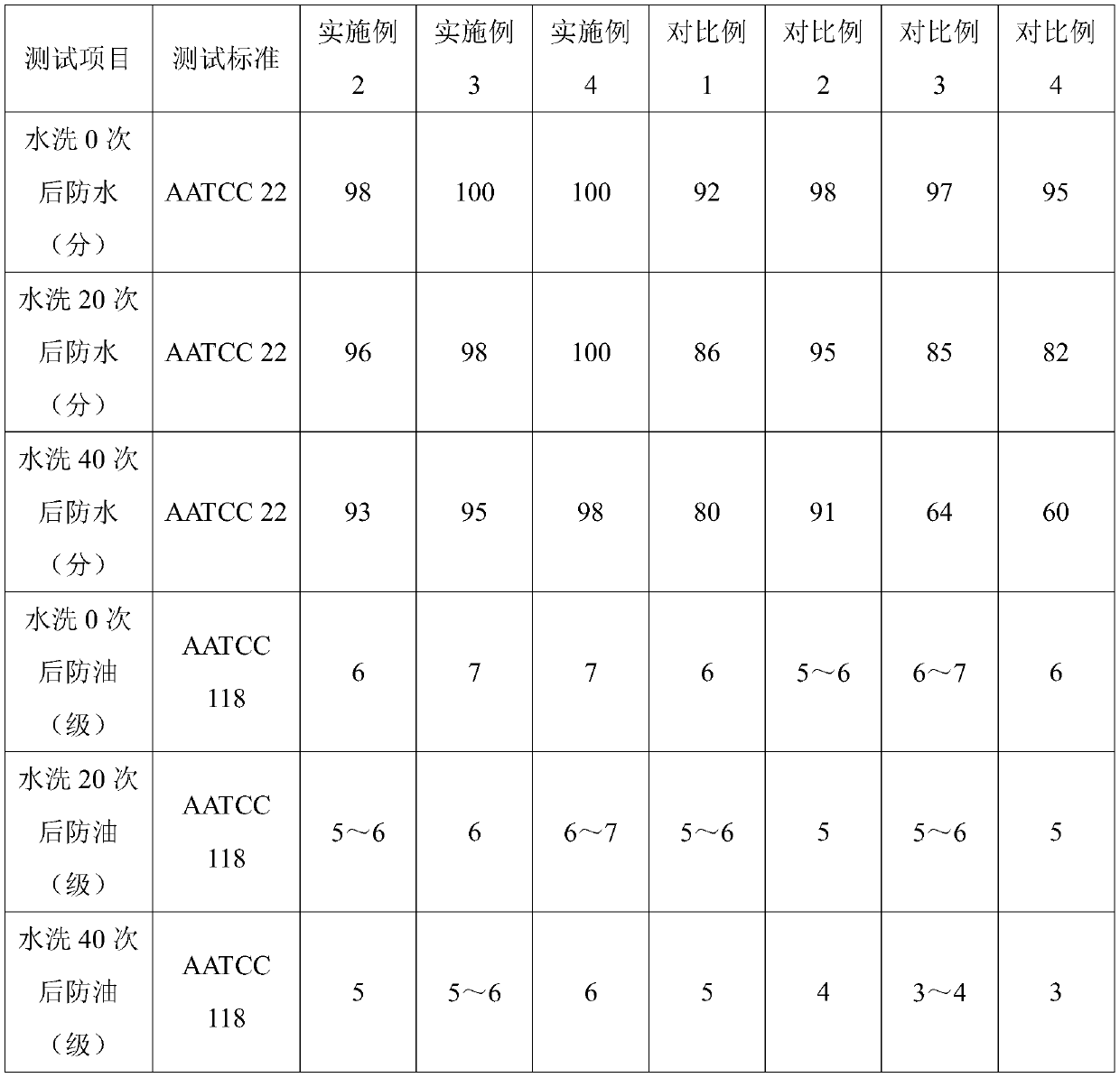

Examples

Embodiment 1

[0039] A waterproof and oil-proof non-woven fabric, which is made of the following raw materials in parts by weight: 65-75 parts of polypropylene, 16-22 parts of maleic anhydride grafted ethylene-octene copolymer, PP-g-AA graft copolymer 8-13 parts of compound, 2-4 parts of amino-modified polysiloxane emulsion, 5-8 parts of polyvinylidene fluoride-hexafluoropropylene copolymer, 4-7 parts of fluorine-containing polyacrylic acid ester, and 9-15 parts of filler.

[0040] Preferably, the waterproof and oil-proof nonwoven fabric is made of the following raw materials in parts by weight: 70 parts of polypropylene, 19.3 parts of maleic anhydride grafted ethylene-octene copolymer, 10.5 parts of PP-g-AA grafted copolymer 3.4 parts of amino-modified polysiloxane emulsion, 6.7 parts of polyvinylidene fluoride-hexafluoropropylene copolymer, 5.2 parts of fluorine-containing polyacrylic acid ester, and 12 parts of filler.

[0041] Preferably, the polypropylene has a melting point of 160-170...

Embodiment 2

[0053] A waterproof and oil-proof non-woven fabric, made of raw materials comprising the following parts by weight: 65 parts of polypropylene, 16 parts of maleic anhydride grafted ethylene-octene copolymer, 8 parts of PP-g-AA graft copolymer, 2 parts of amino-modified polysiloxane emulsion, 5 parts of polyvinylidene fluoride-hexafluoropropylene copolymer, 4 parts of fluorine-containing polyacrylic acid ester, and 9 parts of filler.

[0054] In this embodiment, the polypropylene has a melting point of 160° C. and a melt index of 12 g / 10 min.

[0055] In this embodiment, the maleic anhydride graft ratio of the maleic anhydride grafted ethylene-octene copolymer is 0.9%.

[0056] In this embodiment, the acrylic acid grafting rate of the PP-g-AA graft copolymer is 1.6%.

[0057] In this embodiment, the filler is nano calcium carbonate.

[0058] In the present embodiment, the manufacturing process of the waterproof and oil-proof non-woven fabric includes the following steps:

[0...

Embodiment 3

[0066] A waterproof and oil-proof non-woven fabric, made of raw materials comprising the following parts by weight: 75 parts of polypropylene, 22 parts of maleic anhydride grafted ethylene-octene copolymer, 13 parts of PP-g-AA graft copolymer, 4 parts of amino-modified polysiloxane emulsion, 8 parts of polyvinylidene fluoride-hexafluoropropylene copolymer, 7 parts of fluorine-containing polyacrylic acid ester, and 15 parts of filler.

[0067] In this embodiment, the polypropylene has a melting point of 170° C. and a melt index of 16 g / 10 min.

[0068] In this embodiment, the maleic anhydride grafting ratio of the maleic anhydride grafted ethylene-octene copolymer is 1.2%.

[0069] In this embodiment, the acrylic acid grafting rate of the PP-g-AA graft copolymer is 2.3%.

[0070] In this embodiment, the filler is nano calcium carbonate.

[0071] In the present embodiment, the manufacturing process of the waterproof and oil-proof non-woven fabric includes the following steps: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com