Preparation method of coating type MOFs/organic composite diaphragm

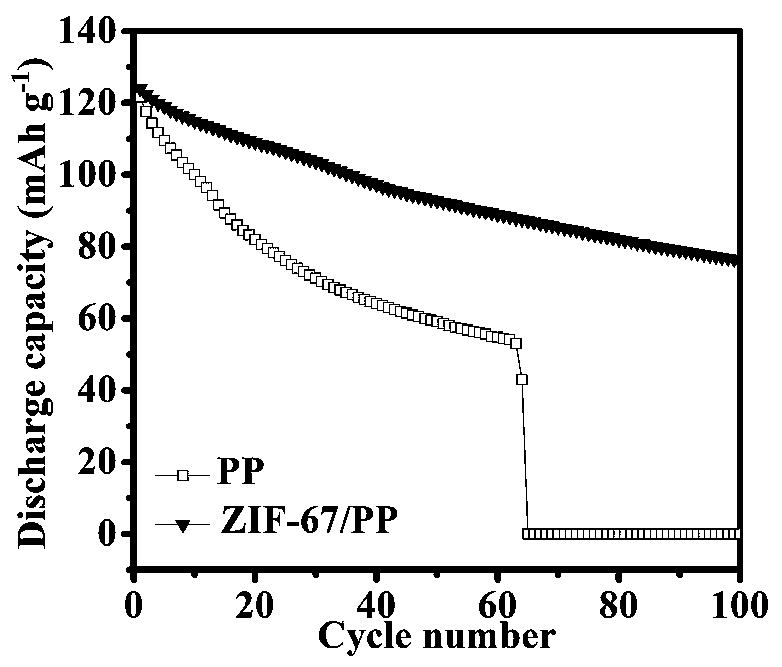

A diaphragm and organic ligand technology, which is applied in the field of preparation of coated MOFs/organic composite diaphragms, can solve the problems of poor flexibility and fragile pure inorganic diaphragms, and achieve the effects of easy operation, increased cycle performance, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) LiNi0.5Co0.2Mn0.3O2 (NCM) electrode material, acetylene black and polyvinylidene fluoride (PVDF) are dispersed in N-methyl-2-pyrrolidone (NMP) at a mass ratio of 8:1:1 After stirring, a uniform slurry is formed, and then the slurry is evenly coated on the aluminum foil, and the coated positive plate is dried in a vacuum drying box to obtain a positive electrode sheet, which is then sliced, pressed and weighed.

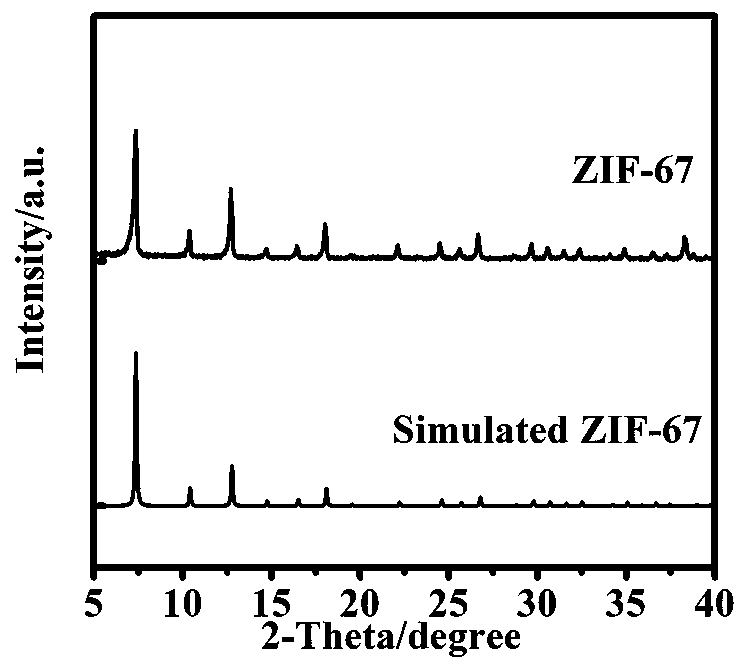

[0015] (2) ZIF-67 is a porous structure assembled by metallic cobalt and organic ligands. The typical synthesis of ZIF-67 particles is to dissolve 1.455g cobalt nitrate hexahydrate and 1.642g 2-methylimidazole in 40ml methanol solution respectively, stir to dissolve, then mix and stir the solution for 10 minutes and age at 25℃ 24h. As the reaction proceeded, purple precipitated ZIFs were produced. The purple precipitate was collected by centrifugation, washed repeatedly with absolute ethanol, and dried in vacuum at 80°C for 24 hours.

[0016] (3) Disperse the p...

Embodiment 2

[0019] (1) LiMn 2 O 4 Electrode material, acetylene black and polyvinylidene fluoride (PVDF) are dispersed in N-methyl-2-pyrrolidone (NMP) at a mass ratio of 8:1:1, and a uniform slurry is formed after stirring, and then the slurry is evenly coated It is clothed on aluminum foil, and the coated positive plate is dried in a vacuum drying box to obtain a positive electrode sheet, which is then sliced, pressed, and weighed.

[0020] (2) ZIF-67 is a porous structure assembled by metallic cobalt and organic ligands. The typical synthesis of ZIF-67 particles is to dissolve 1.455g cobalt nitrate hexahydrate and 1.642g 2-methylimidazole in 40ml methanol solution respectively, stir to dissolve, then mix and stir the solution for 10 minutes and age at 25℃ 24h. As the reaction proceeded, purple precipitated ZIFs were produced. The purple precipitate was collected by centrifugation, washed repeatedly with absolute ethanol, and dried in vacuum at 80°C for 24 hours.

[0021] (3) Disperse the p...

Embodiment 3

[0024] (1) LiMn 2 O 4 Electrode material, acetylene black and polyvinylidene fluoride (PVDF) are dispersed in N-methyl-2-pyrrolidone (NMP) at a mass ratio of 8:1:1, and a uniform slurry is formed after stirring, and then the slurry is evenly coated It is clothed on aluminum foil, and the coated positive plate is dried in a vacuum drying box to obtain a positive electrode sheet, which is then sliced, pressed, and weighed.

[0025] (2) ZIF-67 is a porous structure assembled by metallic cobalt and organic ligands. The typical synthesis of ZIF-67 particles is to dissolve 1.455g cobalt nitrate hexahydrate and 1.642g 2-methylimidazole in 40ml methanol solution respectively, stir to dissolve, then mix and stir the solution for 10 minutes and age at 25℃ 24h. As the reaction proceeded, purple precipitated ZIFs were produced. The purple precipitate was collected by centrifugation, washed repeatedly with absolute ethanol, and dried in vacuum at 80°C for 24 hours.

[0026] (3) Disperse the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com