Method for dynamically adsorbing heavy metals in solution and application thereof

A dynamic adsorption, heavy metal technology, applied in the direction of solid adsorbent liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of high cost, difficult to apply on a large scale, low adsorption capacity, etc., to achieve low cost, easy recovery and Reusable, fast mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

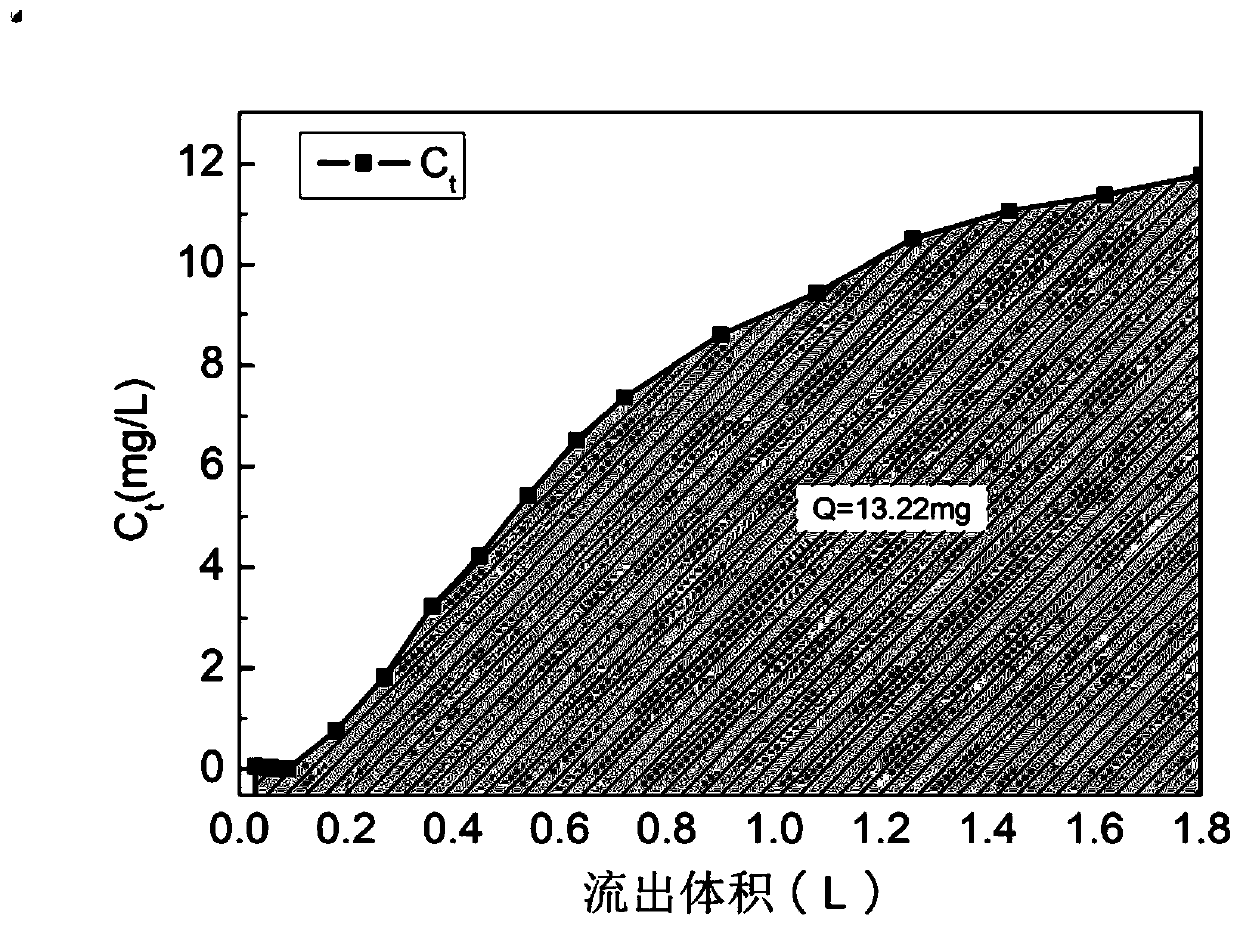

[0065] This embodiment provides a method for dynamically adsorbing uranium metal in a solution and a method for calculating the amount of uranium adsorbed.

[0066] 1. Preparation of functional fiber membrane

[0067] (1) Preparation of grafted cellulose: Weigh 1g of cellulose and disperse it in 150mL of water to mechanically break up, then add the evenly dispersed cellulose solution into a 250mL three-neck flask, keep stirring in a constant temperature water bath at 60°C, and keep Nitrogen was introduced. After adding 0.54mL of sulfuric acid (50% v / v) solution, continue to stir for 30min; dissolve 0.45g of ammonium persulfate into 10mL of deionized water, then slowly add to the above solution and continue to stir for 30min; slowly add 10mL of Acrylonitrile, continue to stir the reaction under nitrogen atmosphere for 2h. After the reaction is completed, the grafted cellulose is directly separated by filtration, washed repeatedly with deionized water, and finally dried and co...

Embodiment 2

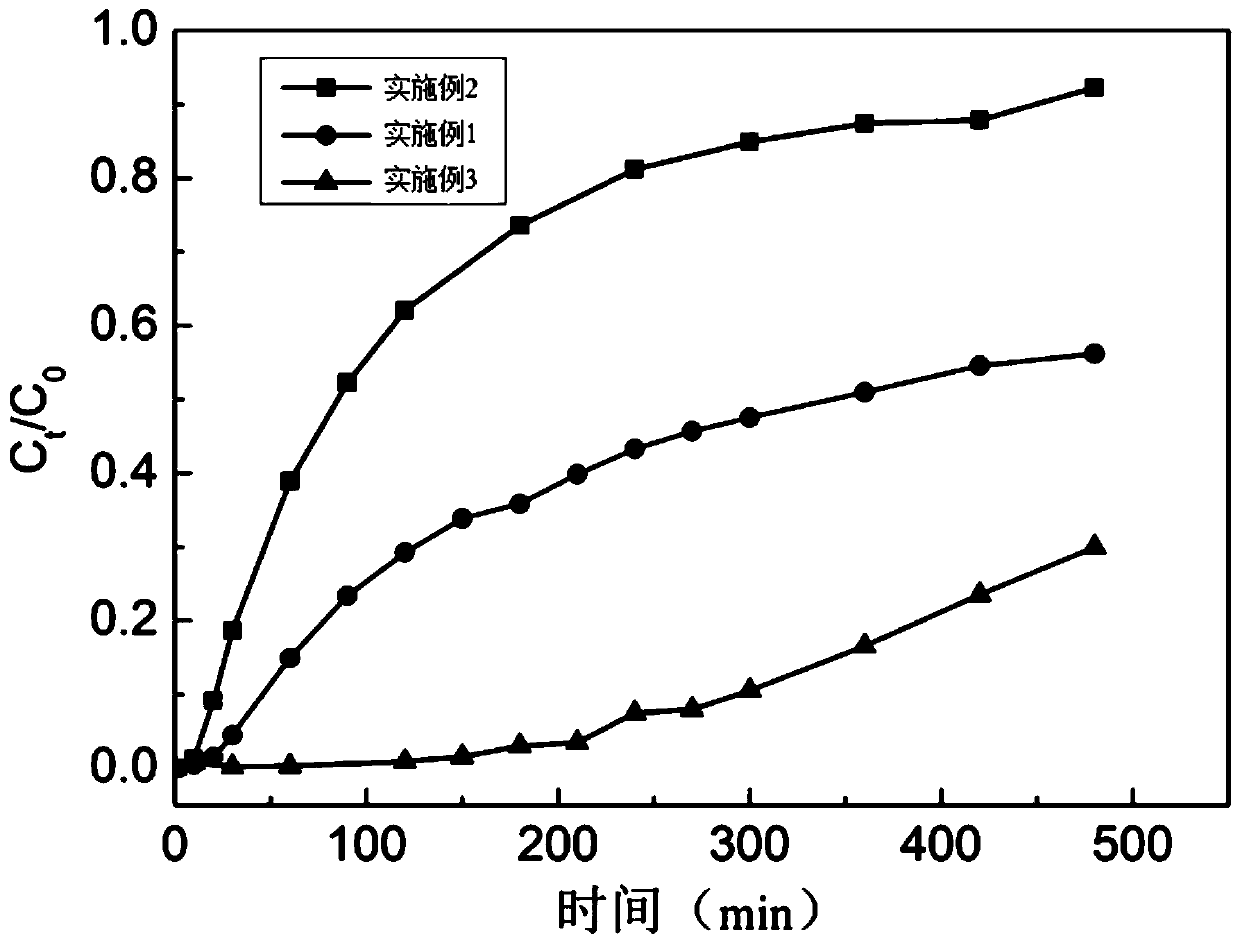

[0079] The difference from Example 1 is that only one polyacrylonitrile fiber membrane is used for dynamic adsorption of heavy metals.

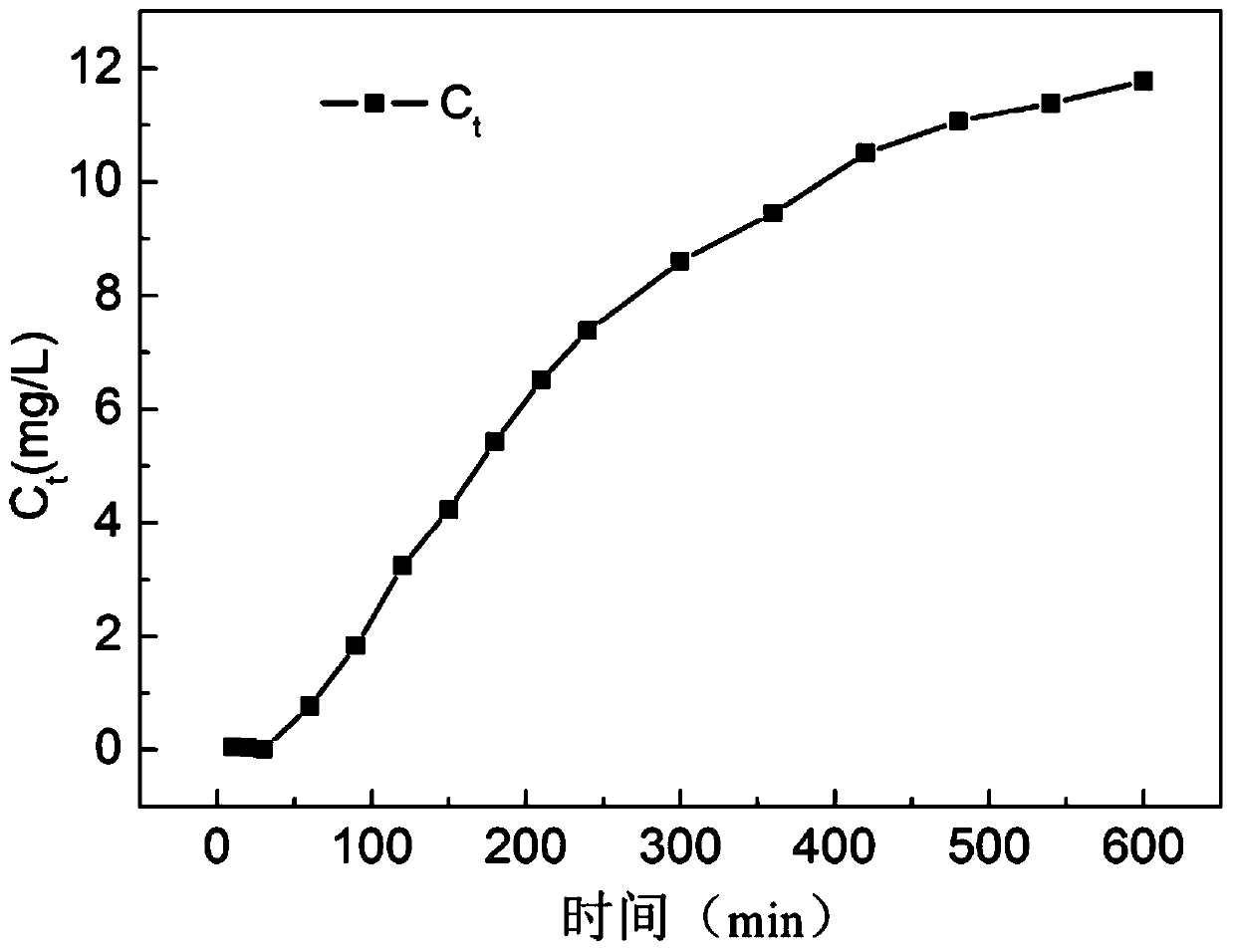

[0080] After calculation, when the breakthrough point is reached, the breakthrough time is 20min, and the solution volume flowing through the functional fiber membrane bed is 60mL, which is equivalent to 26 bed volumes. After adsorption for 600min, the adsorption capacity of uranium on the bed is Q 600min = 6 mg.

Embodiment 3

[0082] The difference from Example 1 is that 3 polyacrylonitrile fiber membranes are used for dynamic adsorption of heavy metals.

[0083] After calculation, when the breakthrough point is reached, the breakthrough time is 298min, and the solution volume flowing through the functional fiber membrane bed is 894mL, which is equivalent to 387 bed volumes. After 600min of adsorption, the adsorption capacity of uranium on the bed is Q 600min = 16 mg.

[0084] The adsorption curve of embodiment 1~3 is as image 3 shown, where C t Indicates the uranium concentration in the effluent, C 0 Represents the uranium concentration in the initial solution. It can be seen that when using 3 functional fiber membranes, the dynamic adsorption efficiency is significantly higher than using 1 or 2 filter membranes, but the amount of uranium adsorbed by each functional fiber membrane is basically the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com