Tellurate-doped scintillation optical fiber and preparation method thereof

A scintillation fiber and tellurite technology, which is applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of inability to meet high-pixel imaging, affecting the light yield of single crystal fiber, and large size, so as to increase the Faraday effect and improve the Light production performance, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

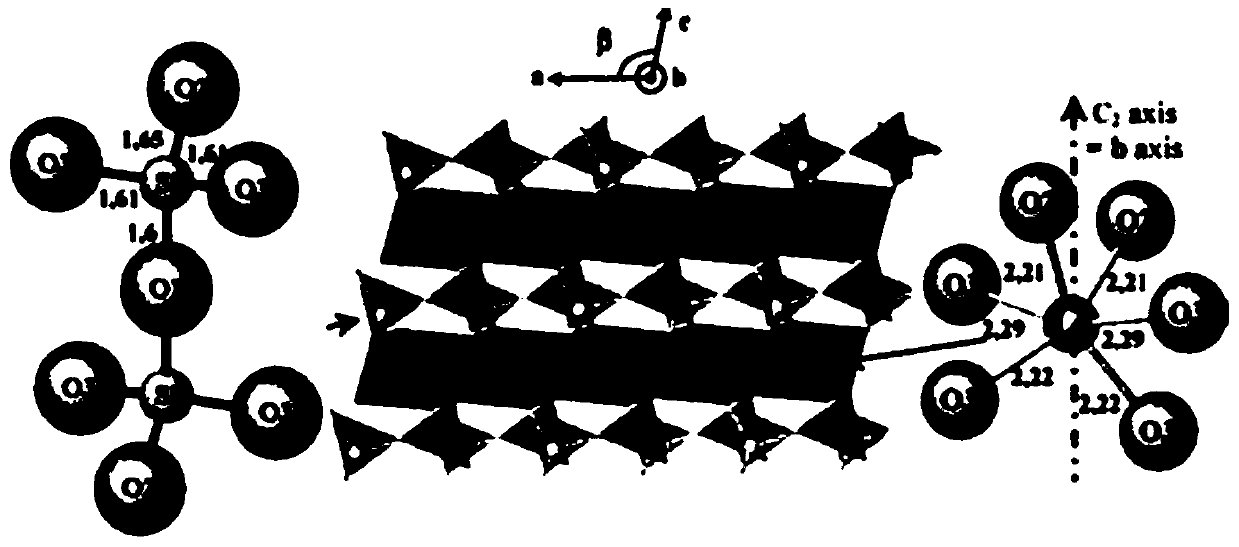

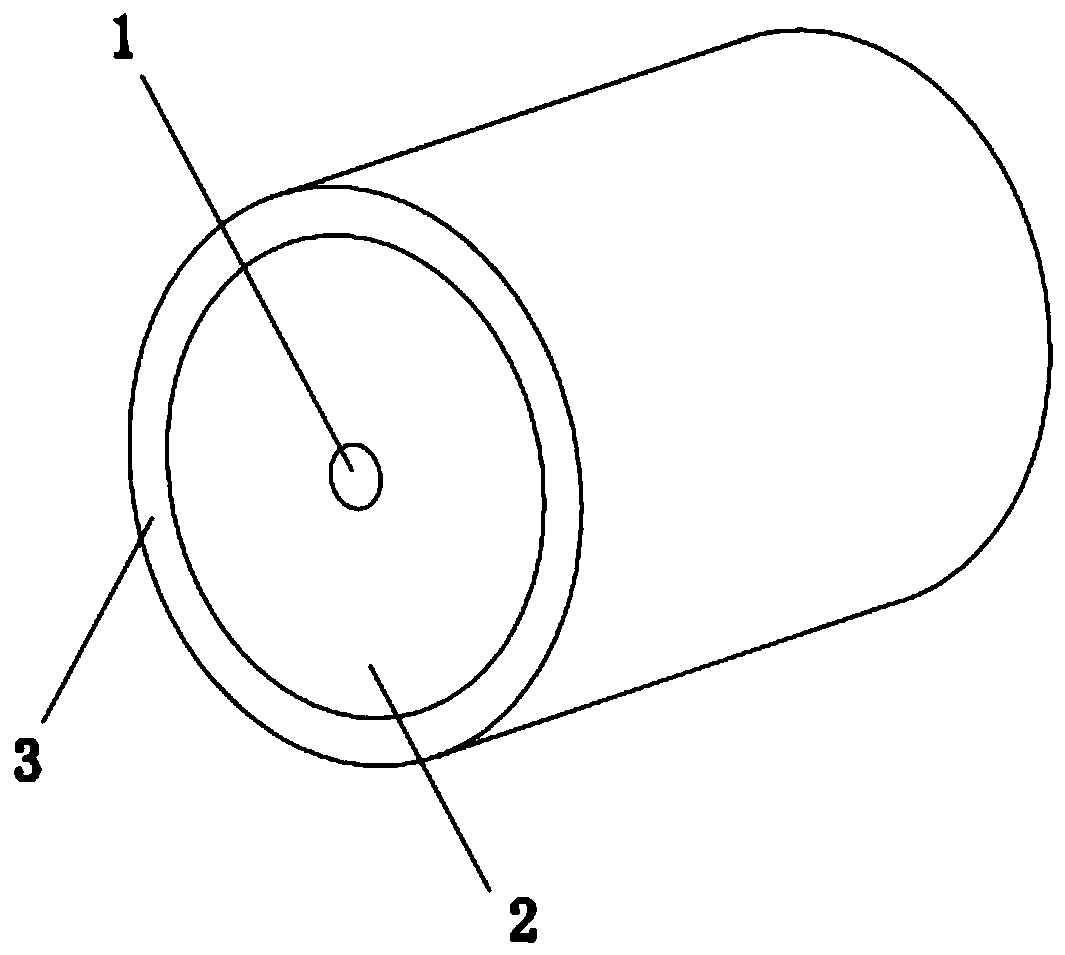

[0026] A tellurate-doped scintillation optical fiber, comprising a core and a cladding covering the outside of the core, the composition of the core is 6 Li 0.2 : Ce 0.2 Lu 2 B 0.2 PbTeSi 2 o 8 (m=0.5, n=0.5), the cladding composition is 0.85TeO 2 0.14PbO0.01B 2 o 3 (x=0.85, y=0.14, z=0.01). The scintillation fiber is prepared by the following method:

[0027] S1: Weigh TeO with a molar ratio of 0.68:0.10:0.01:0.02:0.02:0.26 2 , PbO, B 2 o 3 、Ce 2 (C 2 o 4 ) 3 , Li 2 CO 3 and LSO, heated to 900°C for melting, and kept for 180 minutes to obtain the material used to prepare the fiber core 6 Li 0.2 : Ce 0.2 Lu 2 B 0.2 PbTeSi 2 o 8 :

[0028] S2: Weigh TeO in proportion 2 、PO 2 and B 2 o 3 , heated to 600-650°C for melting, and kept for 180 minutes to obtain the material 0.85TeO 2 0.14PbO0.01B 2 o 3 ;

[0029] S3: will 6 Li 0.2 : Ce 0.2 Lu 2 B 0.2 PbTeSi 2 o 8 The static material is cut into a cylindrical rod as the core, and the core is coa...

Embodiment 2

[0032] A tellurate-doped scintillation optical fiber, comprising a core and a cladding covering the outside of the core, the composition of the core is 6 Li 0.2 : Ce 0.2 Lu 2 B 0.2 PbTe 2 Si 2 o 10 (m=0.5, n=1), the cladding composition is 0.8TeO 2 0.13PbO0.02B 2 o 3 (x=0.8, y=0.13, z=0.02). The scintillation fiber is prepared by the following method:

[0033] S1: Weigh TeO with a molar ratio of 0.58:0.20:0.01:0.02:0.02:0.26 2 , PbO, B 2 o 3 、Ce 2 (C 2 o 4 ) 3 , Li 2 CO 3 and LSO, heated to 950°C for melting, and kept for 180 minutes to obtain the material used to prepare the fiber core 6 Li 0.2 : Ce 0.2 Lu 2 B 0.2 PbTe 2 Si 2 o 10 :

[0034] S2: Weigh TeO in proportion 2 、PO 2 and B 2 o 3 , heated to 600-650°C for melting, and kept for 180 minutes to obtain the material 0.8TeO 2 0.13PbO0.02B 2 o 3 ;

[0035] S3: will 6 Li 0.2 : Ce 0.2 Lu 2 B 0.2 PbTe 2 Si 2 o 10 The static material is cut into a cylindrical rod as the core, and the c...

Embodiment 3

[0038] A tellurate-doped scintillation optical fiber, comprising a core and a cladding covering the outside of the core, the composition of the core is 6 Li 0.1 : Ce 0.1 LuB 0.1 PbTeSiO 4 (m=1, n=1), the cladding composition is 0.8TeO 2 0.14PbO0.01B 2 o 3 (x=0.8, y=0.14, z=0.01). The scintillation fiber is prepared by the following method:

[0039] S1: Weigh TeO with a molar ratio of 0.63:0.15:0.01:0.02:0.02:0.26 2 , PbO, B 2 o 3 、Ce 2 (C 2 o 4 ) 3 , Li 2 CO 3 and LSO, heated to 900°C for melting, and kept for 180 minutes to obtain the material used to prepare the fiber core 6 Li 0.1 : Ce 0.1 LuB 0.1 PbTeSiO 4 :

[0040] S2: Weigh TeO in proportion 2 、PO 2 and B 2 o 3 , heated to 600-650°C for melting, and kept for 180 minutes to obtain the material 0.8TeO 2 0.14PbO0.01B 2 o 3 ;

[0041] S3: will 6 Li 0.1 : Ce 0.1 LuB 0.1 PbTeSiO 4 The static material is cut into a cylindrical rod as the core, and the core is coated with 0.8TeO 2 0.14PbO0.01B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Core diameter | aaaaa | aaaaa |

| Cladding diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com