A high-strength, high-heat-resistant, flame-retardant transparent polycarbonate resin and its preparation method

A resin and flame retardant technology, applied in the field of polymer materials, can solve the problems of high price, poor heat resistance of phosphorus-based flame retardants, affecting PC light transmittance and impact strength, etc., and achieve the effect of improving flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

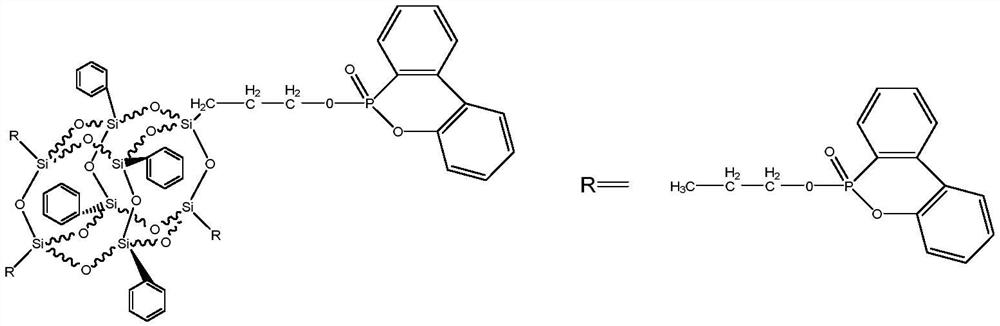

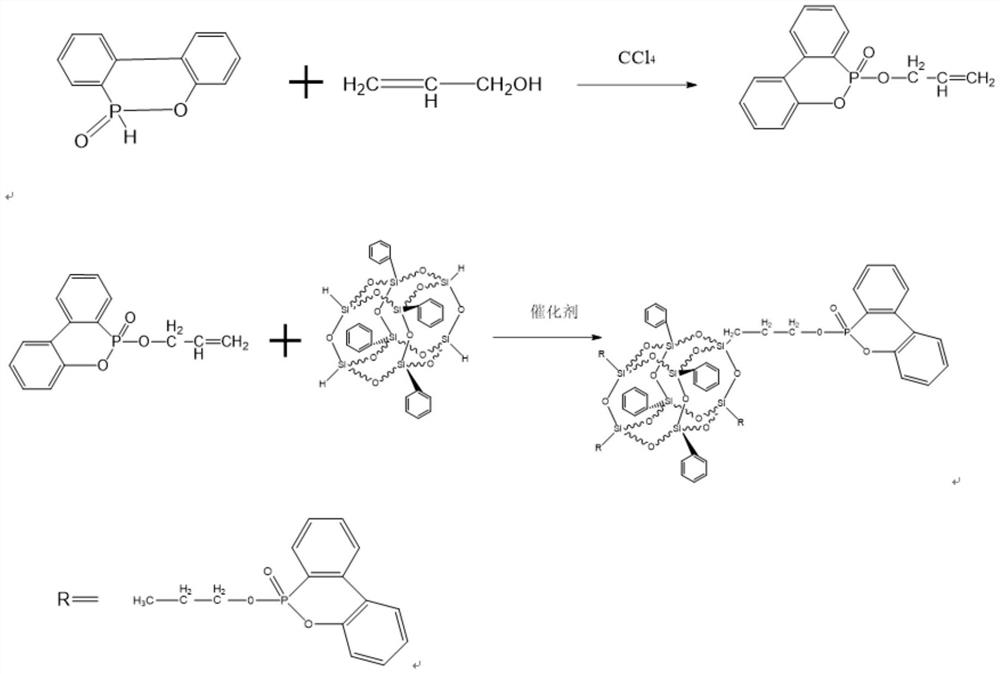

[0029] The synthesis of embodiment 1 phosphorus silicon flame retardant

[0030] (1) Take 4.32g DOPO and add 20ml of dichloromethane into a three-necked flask equipped with a condensing reflux device, and slowly add 4ml of CCl dropwise under ice bath conditions 4 .After the dropwise addition, continue to add 1.2g propenyl alcohol and 4ml triethylamine to the system. After a period of reaction, raise the temperature of the system, keep it warm for a period of time, and then lower it to room temperature. Filter the crude product, wash it, and dry it to obtain propylene Alcohol-modified DOPO.

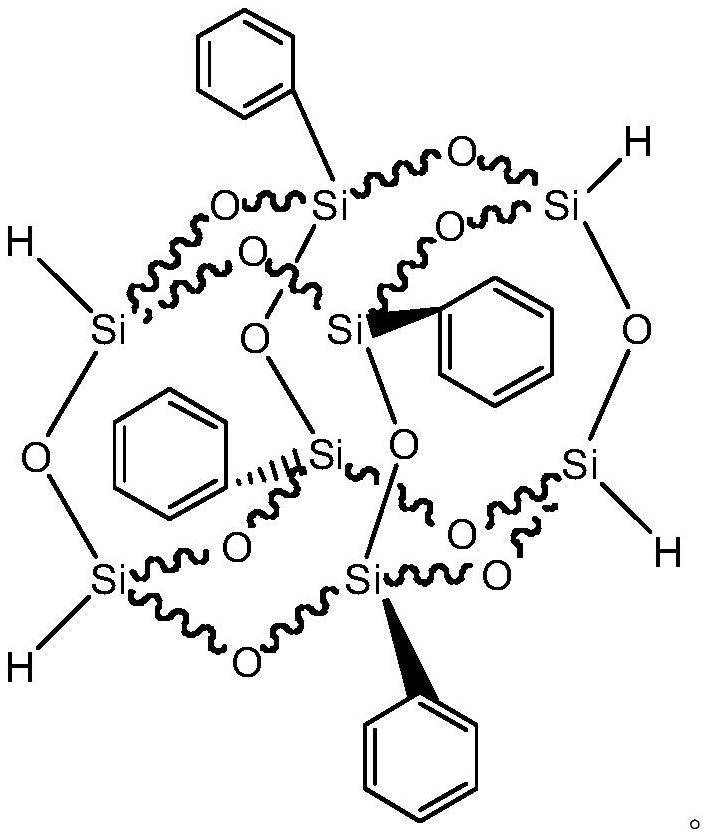

[0031] (2) Dissolve 11.5 g of the product in step (1) in cyclohexane, add 7.52 g (0.01 mol) of phenyl hydrogen-containing silicone resin to it, stir evenly, add Karstedt catalyst after removing the solvent under reduced pressure, and finally react to obtain target product.

Embodiment 2-6

[0032] Embodiment 2-6 high strength, the preparation of high heat-resistant flame-retardant transparent polycarbonate resin

[0033] Embodiment 2-6, the weight percent of each component in each embodiment is as shown in table 1.

[0034] The specific steps are as follows. Dry the PC resin at a temperature of 120°C for 4 hours, and mix the PC resin and the flame retardant according to the proportion. It is added to a twin-screw extruder for melt blending and extrusion; wherein the temperature of each zone of the twin-screw extruder is 260°C, 265°C, 270°C, 270°C, 265°C, and the head temperature is 270°C, The extruded raw materials are drawn, granulated, and dried to obtain a transparent flame-retardant PC material. The obtained transparent PC material is injected into a sample strip with a thickness of 3.0mm under the injection molding machine, and the performance test is performed according to the corresponding standard test (see Table 2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com