Dielectric constant-adjustable composite resistive film and preparation method thereof

A composite resistance and dielectric constant technology, which is applied in the field of composite resistance film and preparation, can solve the problems of difficult parameter adjustment, small adjustment range, and small quality, and achieve good optical characteristics, electrical and thermal conductivity, adjustable parameters, The effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

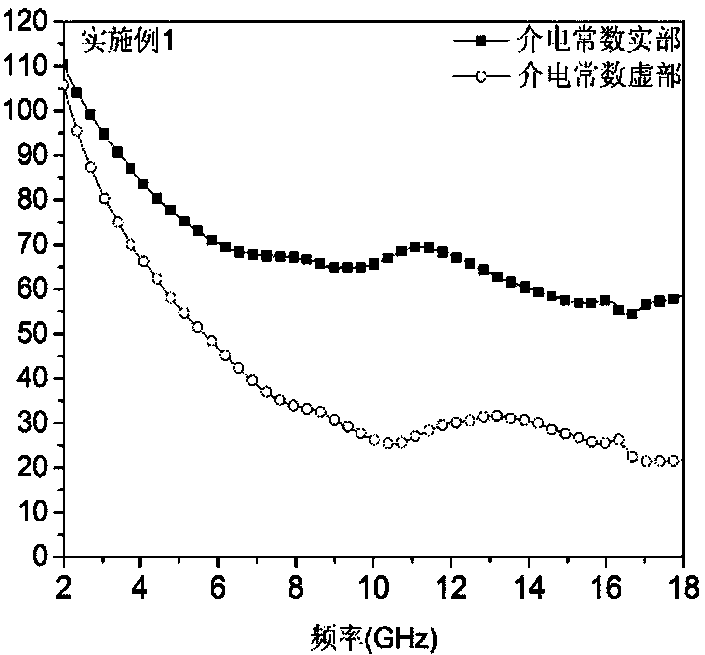

Embodiment 1

[0027] Step 1: add 40g of the mixture of carbon black and graphene in 100g deionized water, wherein the mass ratio of carbon black and graphene is 25:2; then add 1.2g sodium dodecyl sulfate (SDS); at room temperature Carry out ball milling, the ball milling speed is 300rad / min, and the ball milling time is 60min, to obtain a carbon black / graphene mixed solution.

[0028] Step 2: Add 1.0g of carbon nanofibers and 0.4g of BYK-190 to the mixed solution of carbon black / graphene prepared in step 1, and perform ultrasonic vibration and mechanical stirring at room temperature at the same time. The ultrasonic vibration power is 400W, and the mechanical stirring The rotational speed was 700 rad / min, and the time of ultrasonic vibration and mechanical stirring was 30 min to obtain a uniformly dispersed carbon black / graphene / carbon nanofiber mixed solution.

[0029] Step 3: in the carbon black / graphene / carbon nanofiber mixed solution that step 2 makes, add 60g aqueous polyurethane resin,...

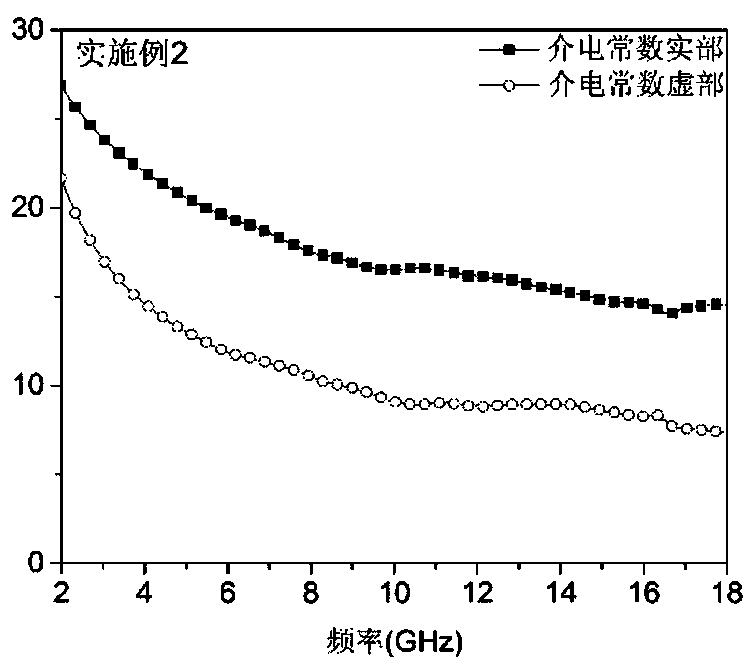

Embodiment 2

[0034] Step 1: add 40g of the mixture of carbon black and graphene in 100g deionized water, wherein the mass ratio of carbon black and graphene is 23:3; then add 1.2g sodium dodecyl sulfate (SDS); at room temperature Carry out ball milling, the ball milling speed is 300rad / min, and the ball milling time is 60min, to obtain a carbon black / graphene mixed solution.

[0035] Step 2: Add 1.2g of carbon nanofibers and 0.6g of BYK-190 to the mixed solution of carbon black / graphene prepared in step 1, and perform ultrasonic oscillation and mechanical stirring at room temperature at the same time. The ultrasonic oscillation power is 400W, and the mechanical stirring The rotational speed was 700 rad / min, and the time of ultrasonic vibration and mechanical stirring was 30 min to obtain a carbon black / graphene / carbon nanofiber mixed solution.

[0036] Step 3: in the carbon black / graphene / carbon nanofiber mixed solution that step 2 makes, add 60g aqueous polyurethane resin, and carry out m...

Embodiment 3

[0041] Step 1: add 40g of the mixture of carbon black and graphene in 100g deionized water, wherein the mass ratio of carbon black and graphene is 21:4; then add 1.2g sodium dodecyl sulfate (SDS); at room temperature Carry out ball milling, the ball milling speed is 300rad / min, and the ball milling time is 60min, to obtain a carbon black / graphene mixed solution.

[0042] Step 2: Add 1.2g of carbon nanofibers and 0.4g of BYK-190 to the carbon black / graphene mixed solution prepared in step 1, and perform ultrasonic oscillation and mechanical stirring at room temperature at the same time. The ultrasonic oscillation power is 400W, and the mechanical stirring speed is 700 rad / min, ultrasonic vibration and mechanical stirring for 30 min, to obtain a carbon black / graphene / carbon nanofiber mixed solution.

[0043] Step 3: in the carbon black / graphene / carbon nanofiber mixed solution that step 2 makes, add 60g aqueous polyurethane resin, carry out mechanical stirring at room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com