Preparation method of anti-aging waterproof coating

A waterproof coating and anti-aging technology, applied in asphalt coatings, coatings, etc., can solve problems such as increased construction costs and maintenance costs, aging and water leakage of waterproof coatings, and unsatisfactory aging resistance, so as to save maintenance costs and prolong service life. , to avoid the effect of aging and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

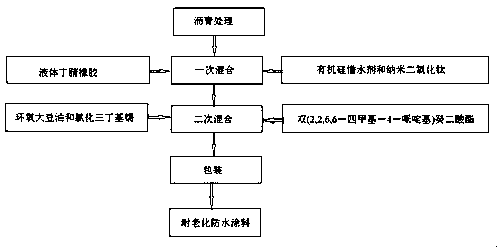

[0024] A preparation method for aging-resistant waterproof paint, comprising the following steps:

[0025] (1) Asphalt treatment: put 90# asphalt in the heating kettle, then add cobalt naphthenate, the addition amount is 21% of the weight of 90# asphalt, heat at a speed of 3°C / min until it is completely melted, keep stirring for 20min, Then add monoalkoxy titanate in the heating kettle, the addition amount is 12% of the 90# asphalt weight, heat preservation and stirring for 40min, the use method of the described anti-aging waterproof coating, must process the asphalt;

[0026] (2) Primary mixing: Add liquid nitrile rubber to the treated asphalt, the amount of liquid nitrile rubber added is 34% of the weight of the treated asphalt, heat and stir for 30 minutes, then add silicone water repellent and nano-titanium dioxide, silicone water repellent The addition amount of the additive is 11% of the weight of the treated asphalt, and the addition of nano-titanium dioxide is 4% of th...

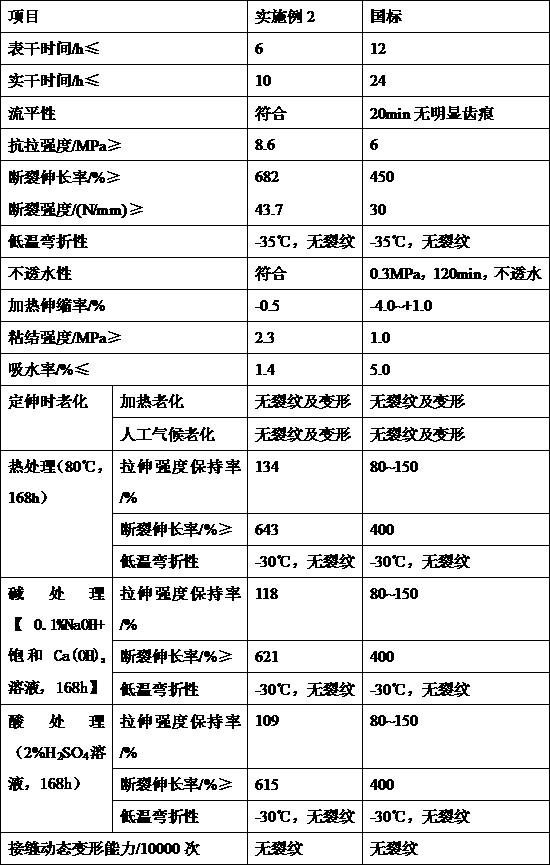

Embodiment 2

[0031] A preparation method for aging-resistant waterproof paint, comprising the following steps:

[0032] (1) Asphalt treatment: put 90# asphalt in a heating kettle, then add cobalt naphthenate, the addition amount is 22% of the weight of 90# asphalt, heat at a speed of 3.5°C / min until it is completely melted, keep stirring for 25 minutes, Then add monoalkoxy titanate in the heating kettle, the addition is 13% of the 90# asphalt weight, heat preservation and stirring for 45min, the use method of the described aging-resistant waterproof coating must be treated asphalt;

[0033] (2) Primary mixing: add liquid nitrile rubber to the treated asphalt, the amount of liquid nitrile rubber added is 35% of the weight of the treated asphalt, keep warm and stir for 35 minutes, then add silicone water repellent and nano-titanium dioxide, silicone water repellent The addition amount of the additive is 12% of the weight of the treated asphalt, and the addition of nano-titanium dioxide is 5%...

Embodiment 3

[0038] A preparation method for aging-resistant waterproof paint, comprising the following steps:

[0039] (1) Asphalt treatment: put 90# asphalt in a heating kettle, then add cobalt naphthenate, the addition amount is 23% of the weight of 90# asphalt, heat at a speed of 4°C / min until it is completely melted, keep stirring for 30min, Then add monoalkoxy titanate in the heating kettle, the addition amount is 14% of the 90# asphalt weight, heat preservation and stirring for 50min, the use method of the described anti-aging waterproof coating, must process the asphalt;

[0040] (2) Primary mixing: add liquid nitrile rubber to the treated asphalt, the amount of liquid nitrile rubber added is 36% of the weight of the treated asphalt, heat preservation and stirring for 40 minutes, then add silicone water repellent and nano-titanium dioxide, silicone water repellent The addition amount of the additive is 13% of the weight of the treated asphalt, and the addition of nano-titanium diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com