Preparation method of high-temperature-resistant polysulfone-based composite insulation paper

A technology of composite insulation and high temperature resistance, which is applied in pulp beating method, special paper, synthetic cellulose/non-cellulose material pulp/paper, etc. It can solve the problems of shortening transformer life, accelerating insulation aging, and poor high temperature resistance. Achieve excellent mechanical properties, ensure electrical insulation properties, improve high temperature resistance and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

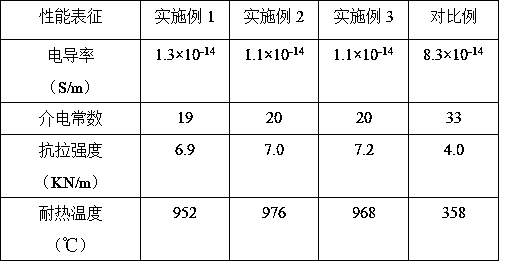

Examples

Embodiment 1

[0039] In terms of parts by weight, weigh 20 parts of polysulfone resin and 80 parts of N,N-dimethylformamide respectively, add polysulfone resin to N,N-dimethylformamide, and rotate at 200r / min at room temperature Stir for 30 minutes to obtain a polysulfone resin solution, place the polysulfone resin solution in an ultrasonic disperser, and oscillate ultrasonically with a power of 300W for 10 minutes at room temperature to obtain a polysulfone resin spinning solution, place the polysulfone resin spinning solution in a high-voltage electrostatic In the syringe of the spinning device, the diameter of the injection needle is 0.1 mm, and the distance between the injection needle and the collection drum is 12 cm. Under the condition of a voltage of 30 kV, the polysulfone resin spinning solution is sprayed to the collection drum at a flow rate of 0.2 mL / h On the top, the collection drum rotates at a speed of 60~80r / min to collect polysulfone fibers, and then weigh 20 parts of nano-s...

Embodiment 2

[0041] In terms of parts by weight, weigh 25 parts of polysulfone resin and 100 parts of N,N-dimethylformamide respectively, add polysulfone resin to N,N-dimethylformamide, and rotate at 225r / min at room temperature Stir for 35 minutes to obtain a polysulfone resin solution, place the polysulfone resin solution in an ultrasonic disperser, and oscillate ultrasonically with a power of 350W for 15 minutes at room temperature to obtain a polysulfone resin spinning solution, place the polysulfone resin spinning solution in a high-voltage electrostatic In the syringe of the spinning device, the diameter of the injection needle is 0.1 mm, and the distance between the injection needle and the collection drum is 14 cm. Under the condition of a voltage of 35 kV, the polysulfone resin spinning solution is sprayed to the collection drum at a flow rate of 0.3 mL / h On the top, the collection drum rotates at a speed of 70r / min to collect polysulfone fibers, and then weigh 25 parts of nano-sil...

Embodiment 3

[0043] In terms of parts by weight, weigh 30 parts of polysulfone resin and 120 parts of N,N-dimethylformamide respectively, add polysulfone resin to N,N-dimethylformamide, and rotate at 250r / min at room temperature Stir for 40 minutes to obtain a polysulfone resin solution, place the polysulfone resin solution in an ultrasonic disperser, and ultrasonically vibrate for 20 minutes at room temperature with a power of 400W to obtain a polysulfone resin spinning solution, place the polysulfone resin spinning solution in a high-voltage electrostatic In the syringe of the spinning device, the diameter of the injection needle is 0.1 mm, and the distance between the injection needle and the collection drum is 16 cm. Under the condition of a voltage of 40 kV, the polysulfone resin spinning solution is sprayed to the collection drum at a flow rate of 0.4 mL / h On the top, the collection drum rotates at a speed of 80r / min to collect polysulfone fibers, and then weigh 30 parts of nano-silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com