Method for antistatic and non-dust-sticking deodorization and formaldehyde and VOCs decomposition

An anti-static and dust technology, applied in separation methods, chemical instruments and methods, heating methods, etc., can solve the problems of non-renewable use, air odor, loss of purification function, etc. blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

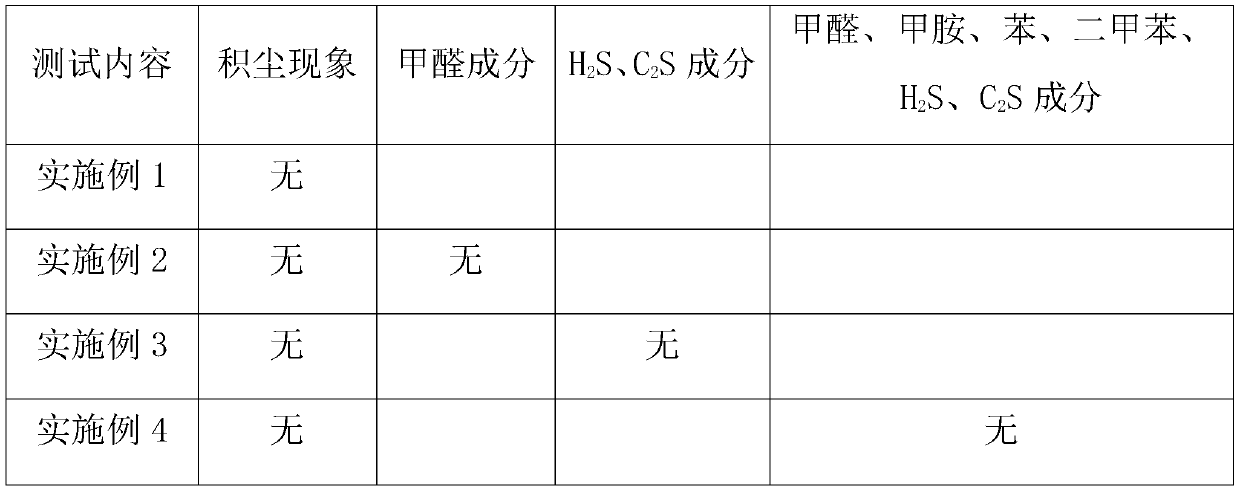

Embodiment 1

[0026] Example 1, dust-proof and anti-static, the test steps are as follows:

[0027] 1) Artificially take conductive fiber and highly active inorganic modified fiber to blend into a filter screen with a filtration accuracy of 400 mesh, a length of 500mm, a width of 200mm, and a thickness of 2mm;

[0028] 2) Install the filter screen vertically in a confined space of 2m*2m*2m, and feed direct current on the filter screen, connect the filter screen to the negative pole of the power supply, and place the positive pole outside the confined space;

[0029] 3) A fan is installed in the confined space to stir, and the particles mixed with cotton fiber particle size of 2.5um, 10um and 15um are placed at the outlet of the fan;

[0030] 4) A row of fans are installed at the outlet of the filter to draw the dusty air in the confined space outward;

[0031] 5) Turn on the stirring fan, let the dust in the confined space disperse, and then turn on the exhaust fan. After one hour, observe...

Embodiment 2

[0032] Embodiment 2, formazan decomposition experiment, test procedure is as follows:

[0033] 1) Artificially take conductive fiber and highly active inorganic modified fiber to blend into a filter screen with a filtration accuracy of 400 mesh, a length of 500mm, a width of 200mm, and a thickness of 2mm;

[0034] 2) Install the filter screen vertically in a confined space of 2m*2m*2m, and connect direct current to the filter screen, connect the filter screen to the negative pole of the power supply, and place the positive pole outside the confined space;

[0035] 3) A fan is installed in the confined space to stir, and the substance containing 20mg / L of formaldehyde is placed at the outlet of the fan;

[0036] 4) A row of fans are installed at the outlet of the filter to draw the dusty air in the confined space outward;

[0037] 5) Turn on the stirring fan, let the formaldehyde in the confined space stir evenly, and then turn on the exhaust fan. After one hour, no formaldehy...

Embodiment 3

[0038] Embodiment 3, H2S, C2S decomposition, test steps are as follows:

[0039] 1) Artificially take conductive fiber and highly active inorganic modified fiber to blend into a filter screen with a filtration accuracy of 400 mesh, a length of 500mm, a width of 200mm, and a thickness of 2mm;

[0040] 2) Install the filter screen vertically in a confined space of 2m*2m*2m, and connect direct current to the filter screen, connect the filter screen to the negative pole of the power supply, and place the positive pole outside the confined space;

[0041] 3) A fan is installed in the confined space to stir, and the space is filled with H 2 S and C 2 S 100mg / L gas;

[0042] 4) A row of fans are installed at the outlet of the filter to draw the dusty air in the confined space outward;

[0043] 5) Turn on the stirring fan to make the closed space H 2 S, C 2 After the S is stirred evenly, the exhaust fan is turned on. After one hour, no H is detected in the detection space. 2 S, C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com