Nitrogen-doped carbon supported tin and tin oxide nano composite material as well as preparation and application thereof

A nanocomposite material, nitrogen-doped carbon technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc. and other issues to achieve the effect of improving stability and conductivity and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]A nanocomposite material of nitrogen-doped carbon supported tin and tin oxide, which is prepared by the following method:

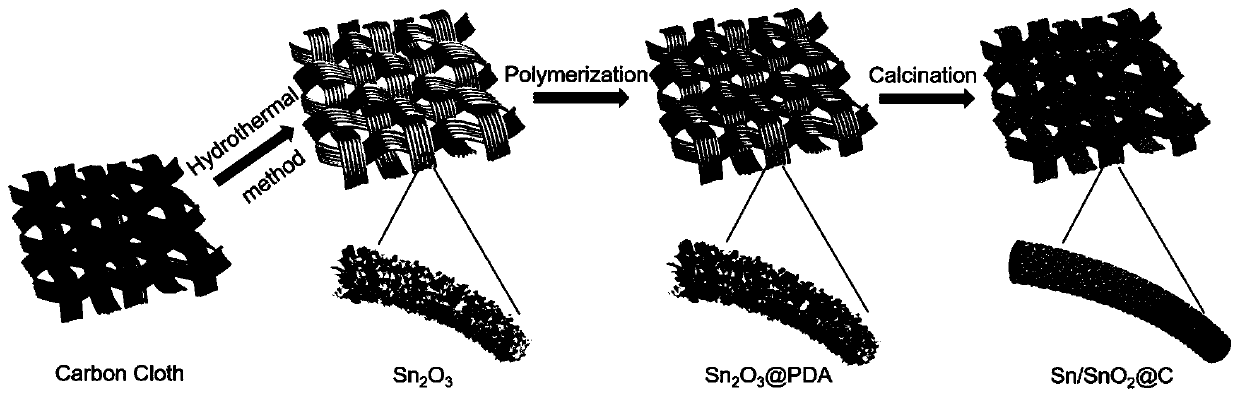

[0043] Synthetic catalyst, its route sees figure 1 Shown:

[0044] A. Cut a 4cm×3cm carbon cloth as the substrate, and ultrasonically pass it through ethanol, 10% nitric acid, and deionized water for 30 minutes respectively;

[0045] B. 5mmol SnCl 2 and 10 mmol NH 4 F is ultrasonically dissolved in 30mL water, poured into a 50mL polytetrafluoroethylene reactor, put the carbon cloth cleaned in step A vertically into the solution, tighten the reactor and put it in an oven, and heat it to 180°C for hydrothermal reaction React for 12 hours, cool down, take out the carbon cloth, wash it with deionized water several times, and place it in an oven at 60°C for drying to obtain a well-ordered Sn 2 o 3 Nanosheet array materials;

[0046] C. Configure Tris buffer solution, dissolve 6g Tris in 1L deionized water, and adjust the pH to 8 with hydrochloric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com