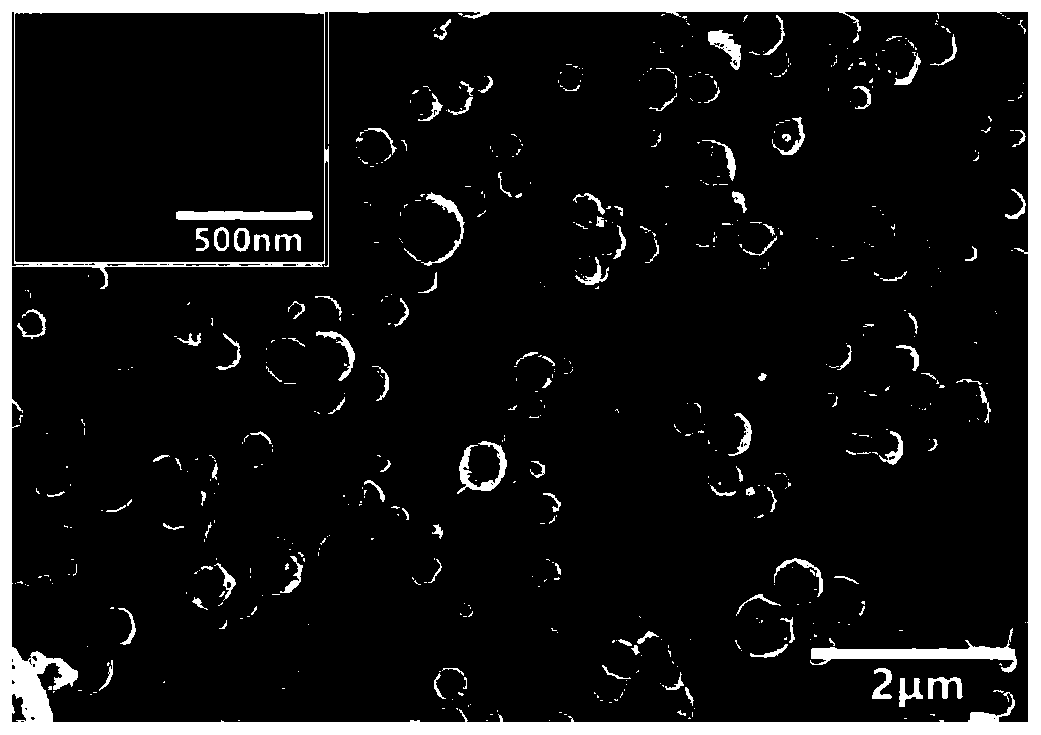

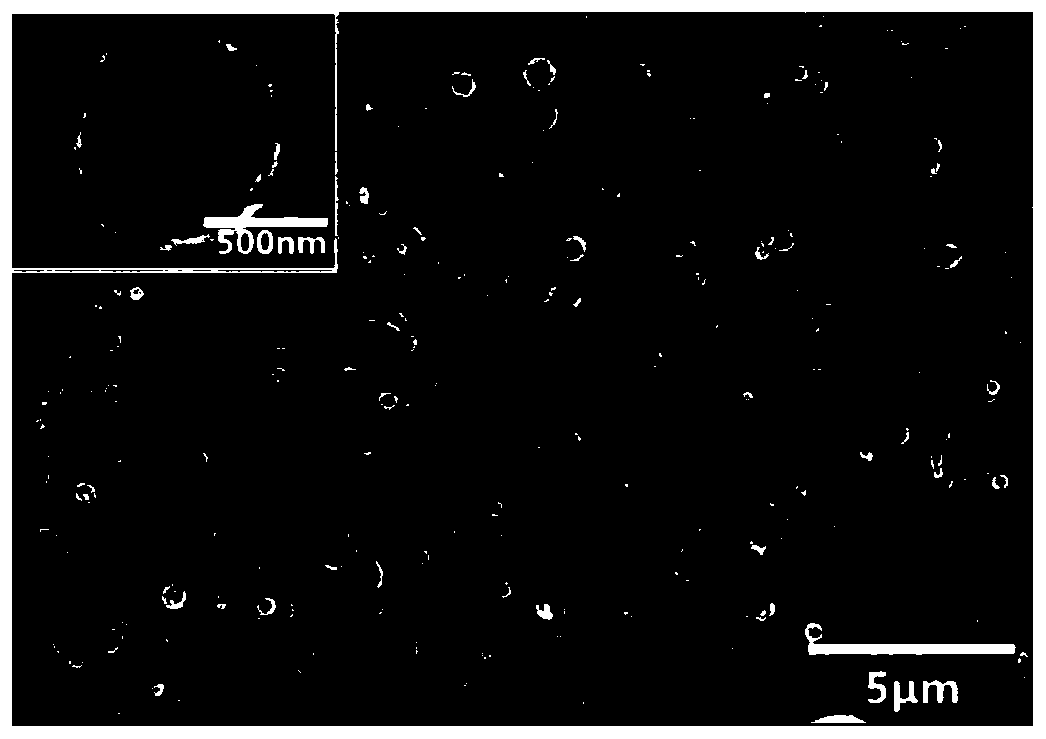

Energetic microsphere formed by compounding polymer, nano-aluminum powder and energetic medicament

A nano-aluminum powder and polymer technology, which is used in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of uneven mixing, agglomeration of components of nano-aluminum composite energetic materials, increase the mechanical strength of microspheres, etc. The appearance is regular, the distribution is uniform, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1. Add 0.03g of fluororubber F2602 and 0.16g of nano-aluminum powder with a median particle size of 10nm into 10mL of a mixed solvent I of ethyl acetate and acetone with a volume ratio of 4:1, and stir vigorously at 25°C for 5 minutes Ultrasound for 1h, followed by stirring for 24h to obtain a stable precursor solution;

[0034] Step 2. Add 1 g of RDX to 12.5 mL of a mixed solution of ethyl acetate and N,N-dimethylformamide with a volume ratio of 10:3, and stir at 25°C for 5 hours to obtain a clear energetic agent solution;

[0035] Step 3. The input end of the inner shaft of the coaxial electrospinning needle is connected to a syringe through a Teflon plastic tube, and the input end of the outer shaft of the coaxial electrospinning needle is connected to another syringe through a Teflon plastic tube. 2. Add the prepared energetic agent solution into the syringe connected to the inner shaft of the coaxial electrospinning needle, and then add the precursor solution ...

Embodiment 2

[0040] Step 1. Add 0.04g of polyvinylidene fluoride and 0.27g of nano-aluminum powder with a median particle size of 10nm to 20.77mL of a mixed solution of ethyl acetate and acetone with a volume ratio of 4:1, and vigorously stir at 25°C for 30min After ultrasonication for 0.5h, followed by stirring for 24h, a stable precursor solution was obtained;

[0041]Step 2. Add 1 g of RDX to 20 mL of a mixed solution of ethyl acetate and N,N-dimethylformamide with a volume ratio of 4:1, and stir at 25°C for 3 hours to obtain a clear energetic agent solution;

[0042] Step 3. The input end of the inner shaft of the coaxial electrospinning needle is connected to a syringe through a Teflon plastic tube, and the input end of the outer shaft of the coaxial electrospinning needle is connected to another syringe through a Teflon plastic tube. 2. Add the prepared energetic agent solution into the syringe connected to the inner shaft of the coaxial electrospinning needle, and then add the precu...

Embodiment 3

[0047] Step 1. Add 0.03g of fluororubber F2602 and 0.16g of nano-aluminum powder with a median particle size of 10nm to 9.4mL of a mixed solution of ethyl acetate and acetone with a volume ratio of 4:1, and stir vigorously at 60°C for 5 minutes Ultrasound for 2h, followed by stirring for 48h to obtain a stable precursor solution;

[0048] Step 2. Add 1 g of hexanitrohexaazaisowurtzitane into 10 mL of a mixed solution of ethyl acetate and N,N-dimethylformamide with a volume ratio of 4:1, and stir at 25°C for 3 hours to obtain a clear Energetic agent solutions;

[0049] Step 3. The input end of the inner shaft of the coaxial electrospinning needle is connected to a syringe through a Teflon plastic tube, and the input end of the outer shaft of the coaxial electrospinning needle is connected to another syringe through a Teflon plastic tube. 2. Add the prepared energetic agent solution into the syringe connected to the inner shaft of the coaxial electrospinning needle, and then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com