Preparation of composite antibacterial ABS material

An ABS material and compound antibacterial technology, applied in the field of new material preparation, can solve the problems of easy breeding of various bacteria and molds, human health hazards, etc., and achieve the effect of significant discoloration effect, reduction of color difference, and small addition amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

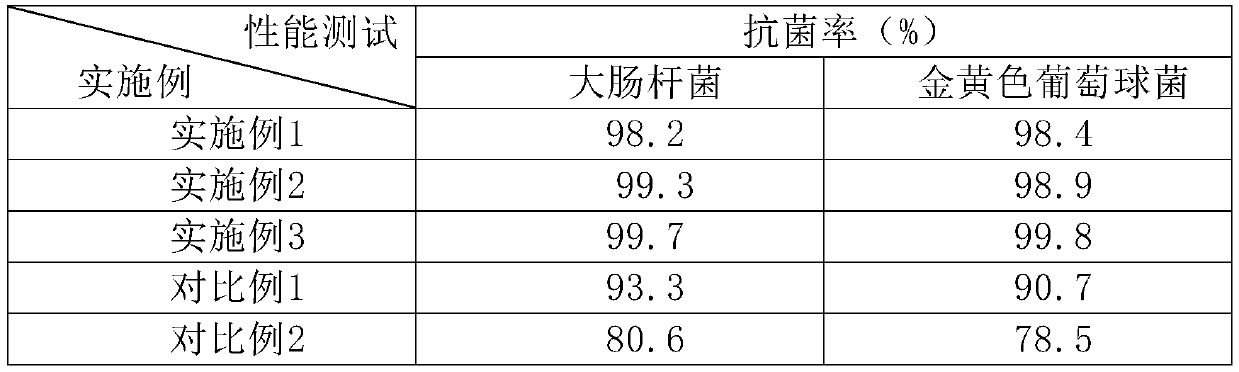

Examples

Embodiment 1

[0028] A composite antibacterial ABS material, comprising the following components by weight: 100 parts of ABS, 0.6 parts of a composite antibacterial agent, 1.5 parts of a silane coupling agent, 0.5 parts of a dispersant, 2 parts of an antioxidant, and 1 part of a discoloration inhibitor; The composite antibacterial agent consists of the following components by weight: 50 parts of ONPURE silver-loaded antibacterial agent, 6 parts of chitosan, 40 parts of nano-zinc oxide, and 10 parts of photosensitizer CCA (chlorophyll cupric acid);

[0029] A kind of preparation method of above-mentioned composite antibacterial ABS material, comprises the following steps:

[0030] Weigh a certain amount of sodium chlorophyll cuprate SCC and place it in a flask, add an appropriate amount of deionized water, stir until the SCC is fully dissolved, then add dropwise 38% hydrochloric acid to make the SCC solution acidic, and place it on a stirrer for stirring After 2 hours of reaction, precipitat...

Embodiment 2

[0035] A composite antibacterial ABS material, comprising the following components by weight: 100 parts of ABS, 0.8 parts of a composite antibacterial agent, 1.5 parts of a silane coupling agent, 0.5 parts of a dispersant, 2 parts of an antioxidant, and 1 part of a discoloration inhibitor; The composite antibacterial agent consists of the following components by weight: 50 parts of ONPURE silver-loaded antibacterial agent, 6 parts of chitosan, 40 parts of nano-zinc oxide, and 10 parts of photosensitizer CCA (chlorophyll cupric acid);

[0036] A kind of preparation method of above-mentioned composite antibacterial ABS material, comprises the following steps:

[0037] Weigh a certain amount of sodium chlorophyll cuprate SCC and place it in a flask, add an appropriate amount of deionized water, stir until the SCC is fully dissolved, then add dropwise 38% hydrochloric acid to make the SCC solution acidic, and place it on a stirrer for stirring After 2 hours of reaction, precipitat...

Embodiment 3

[0042] A composite antibacterial ABS material, comprising the following components by weight: 100 parts of ABS, 1 part of composite antibacterial agent, 1.5 parts of silane coupling agent, 0.5 part of dispersant, 2 parts of antioxidant, 1 part of discoloration inhibitor; The composite antibacterial agent is composed of the following components by weight: 50 parts of ONPURE silver-loaded antibacterial agent, 6 parts of chitosan, 40 parts of nano-zinc oxide, and 10 parts of photosensitizer CCA (chlorophyll cupric acid);

[0043] A kind of preparation method of above-mentioned composite antibacterial ABS material, comprises the following steps:

[0044] Weigh a certain amount of sodium chlorophyll cuprate SCC and place it in a flask, add an appropriate amount of deionized water, stir until the SCC is fully dissolved, then add dropwise 38% hydrochloric acid to make the SCC solution acidic, and place it on a stirrer for stirring After 2 hours of reaction, precipitation can be observe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com