Preparation and regeneration method of circulating copper salt dechlorinating agent

A dechlorination agent and copper salt technology, which is applied in the field of preparation and regeneration of circulating copper salt dechlorination agent, can solve the problems of low dechlorination efficiency, insufficient self-production rate of copper slag and copper salt, etc., and achieve good dechlorination effect , High dechlorination efficiency, guaranteed purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

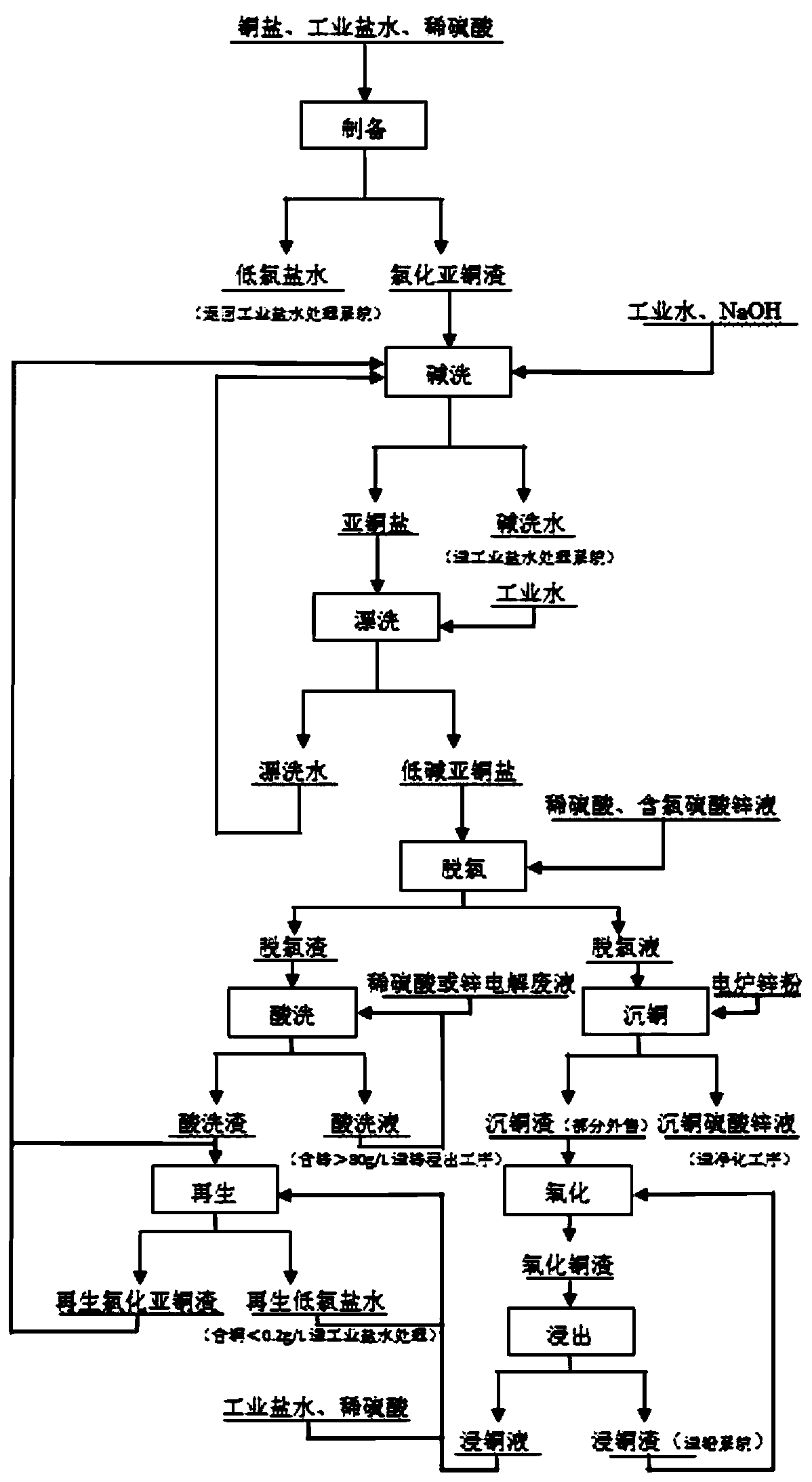

[0024] A method for preparing and regenerating a circulating copper salt dechlorination agent, comprising the steps of:

[0025] 1) Preparation: Dissolve 6 tons of copper slag containing 50% copper in 45m 3 In the industrial brine containing 90g / L chlorine, add sulfuric acid to adjust the pH value to 2.5, then add 9.4 tons of copper sulfate pentahydrate, control the reaction temperature to 60°C, and control the pH value to 3.0 during the process. After stirring for 1.5 hours, filter to produce low-chlorine brine and 9 tons of cuprous chloride slag containing 60% copper, and low-chlorine brine are sent to the industrial brine treatment system;

[0026] 2) Alkali washing: use 10m each time 3Industrial water or step 3) rinsing water to slurry the cuprous chloride slag in step 1) or step 6) regenerated cuprous chloride slag, control the liquid-solid ratio to 3:1, the temperature is 50°C, and adjust the pH value with sodium hydroxide 9.0, after stirring for 40 minutes, filter, an...

Embodiment 2

[0036] A method for preparing and regenerating a circulating copper salt dechlorination agent, comprising the steps of:

[0037] 1) Preparation: Dissolve 6 tons of copper slag containing 50% copper in 45m 3 In the industrial brine containing 90g / L chlorine, add sulfuric acid to adjust the pH value to 3.0, then add 9.4 tons of copper sulfate pentahydrate, control the reaction temperature to 70°C, control the pH value to 3.2 during the process, stir for 1.5 hours and then filter to produce low-chlorine brine and 9 tons of cuprous chloride slag containing 60% copper, and low-chlorine brine are sent to the industrial brine treatment system;

[0038] 2) Alkali washing: use 15m each time 3 Industrial water or step 3) rinsing water slurry the cuprous chloride slag of step 1) or step 6) regenerated cuprous chloride slag, control the liquid-solid ratio to 4:1, the temperature is 60°C, and adjust the pH value with sodium hydroxide 10.0, after stirring for 50 minutes, filter, and produ...

Embodiment 3

[0048] A method for preparing and regenerating a circulating copper salt dechlorination agent, comprising the steps of:

[0049] 1) Preparation: Dissolve 6 tons of copper slag containing 50% copper in 45m 3 In the industrial brine containing 90g / L chlorine, add sulfuric acid to adjust the pH value to 3.5, then add 9.4 tons of copper sulfate pentahydrate, control the reaction temperature to 75°C, control the pH value to 3.5 during the process, and filter after stirring for 1.5 hours to produce low-chlorine brine and 9 tons of cuprous chloride slag containing 60% copper, and low-chlorine brine are sent to the industrial brine treatment system;

[0050] 2) Alkali washing: use 20m each time 3 Industrial water or step 3) rinsing water slurry the cuprous chloride slag of step 1) or step 6) regenerated cuprous chloride slag, control the liquid-solid ratio to 6:1, the temperature is 70°C, and adjust the pH value with sodium hydroxide 11.0, stirred for 60 minutes and then filtered to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com