Plant functional natural silk and preparation method thereof

A natural silk and functional technology, applied in animal fiber, textiles, papermaking, fiber treatment, etc., can solve the problems of incomplete reaction, ineffective effect, and numerous reagents, and achieve good physical properties and excellent antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

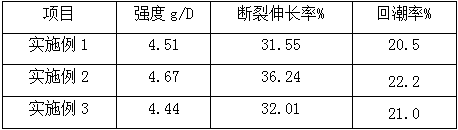

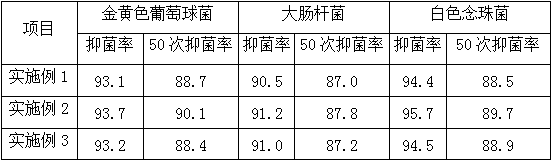

Examples

Embodiment 1

[0037] Example 1 A plant functional natural silk and its preparation method

[0038] Step 1, preparation of treatment solution

[0039] The treatment liquid includes the following raw materials: sodium alkylbenzene sulfonate, sodium silicate, pinpinga, cocoyl glucoside and water; in parts by weight, 50 parts of sodium alkylbenzene sulfonate, 32 parts of sodium silicate, Pingpingjia 15 parts, Coco Glucoside 25 parts and Water 90 parts.

[0040] The coco-based glucoside has a free fatty alcohol content <0.2%, and a surface tension of 28mN / m;

[0041] The sodium silicate has a CAS number of 1334-09-8, an active ingredient content of 98%, and a particle size of 100 mesh;

[0042] The preparation method of the treatment liquid is as follows: first mix sodium alkylbenzene sulfonate, sodium silicate, Pingping and water, and then add cocoyl glucoside and stir and mix.

[0043] Step 2. Micro-processing of natural silk

[0044] Select silk, remove granular impurities, discard natural ...

Embodiment 2

[0054] Embodiment 2 A kind of plant functional natural silk and preparation method thereof

[0055] Step 1, preparation of treatment solution

[0056] The treatment liquid includes the following raw materials: sodium alkylbenzene sulfonate, sodium silicate, Pingpinga, coconut oil glucoside and water; in parts by weight, 65 parts of sodium alkylbenzene sulfonate, 20 parts of sodium silicate, Pingpingjia 22 parts, coconut oil glucoside 20 parts and water 150 parts.

[0057] The coco-based glucoside has a free fatty alcohol content <0.2%, and a surface tension of 28mN / m;

[0058] The sodium silicate has a CAS number of 1334-09-8, an active ingredient content of 98%, and a particle size of 100 mesh;

[0059] The preparation method of the treatment liquid is as follows: first mix sodium alkylbenzene sulfonate, sodium silicate, Pingping and water, and then add cocoyl glucoside and stir and mix.

[0060] Step 2. Micro-processing of natural silk

[0061] Select silk, remove granul...

Embodiment 3

[0071] Embodiment 3 A kind of plant functional natural silk and preparation method thereof

[0072] Step 1, preparation of treatment solution

[0073] The treatment liquid includes the following raw materials: sodium alkylbenzenesulfonate, sodium silicate, pinpinga, cocoyl glucoside and water; in parts by weight, 80 parts of sodium alkylbenzenesulfonate, 12 parts of sodium silicate, Pingpingjia 25 parts, Coco Glucoside 15 parts and Water 160 parts.

[0074] The coco-based glucoside has a free fatty alcohol content <0.2%, and a surface tension of 28mN / m;

[0075] The sodium silicate has a CAS number of 1334-09-8, an active ingredient content of 98%, and a particle size of 100 mesh;

[0076] The preparation method of the treatment liquid is as follows: first mix sodium alkylbenzene sulfonate, sodium silicate, Pingping and water, and then add cocoyl glucoside and stir and mix.

[0077] Step 2. Micro-processing of natural silk

[0078] Select silk, remove granular impurities, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com