Cage-like sampling device for glow discharge mass spectrometry and sample test method

A technology of glow discharge mass spectrometry and sample injection device, which is applied in the direction of material analysis, measurement device, and material analysis by electromagnetic means, which can solve the problems of affecting the detection speed, increasing the detection cost, and test failure, etc., to improve the signal strength of the sample , widen the size range and reduce the cost of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

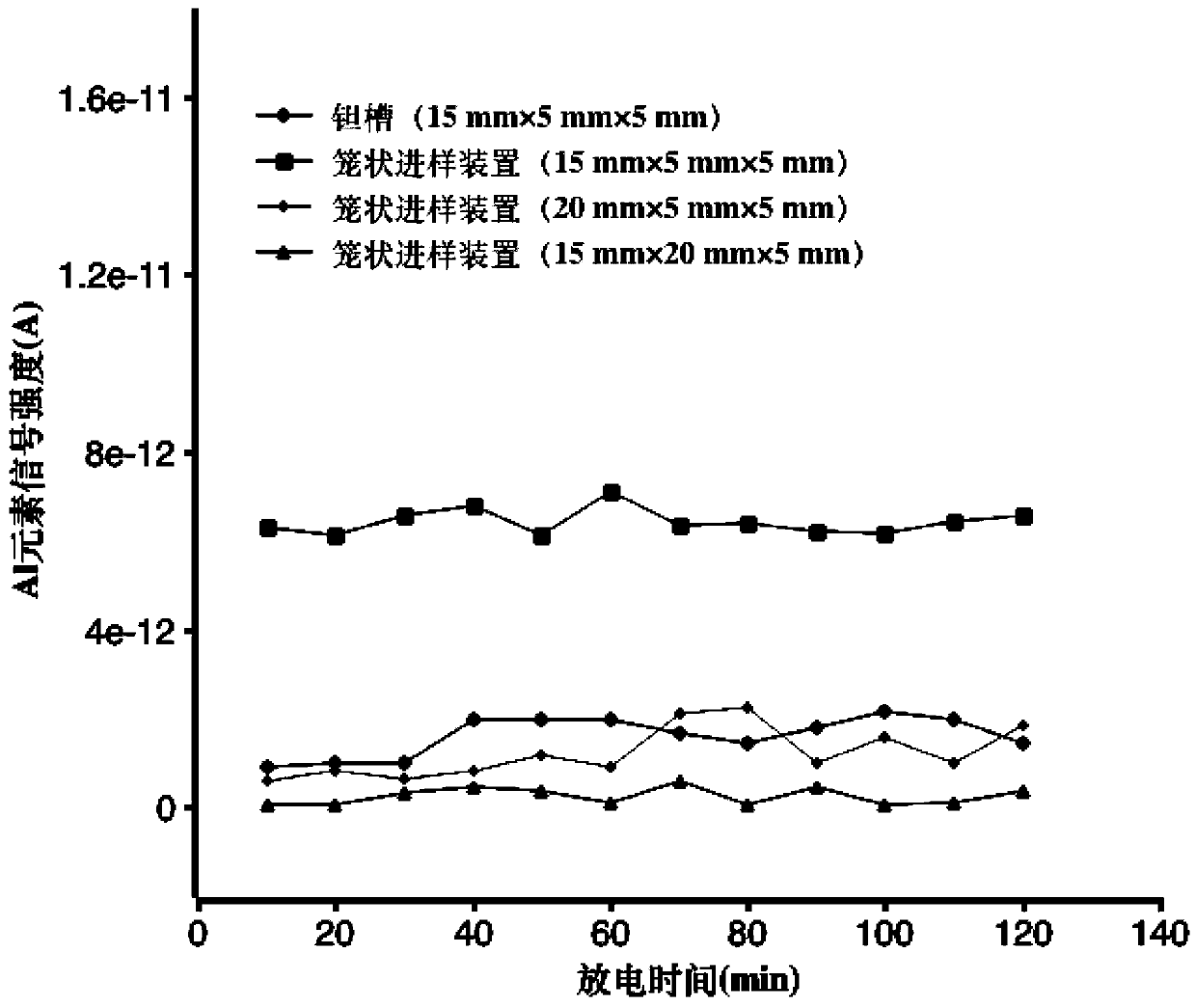

Embodiment 1

[0048] Cage tantalum slots (a, b, c), tantalum slots (d), granular Al 2 o 3 Dilute nitric acid (preferably 1:1 nitric acid (HNO 3 ) and ultrapure water), ultrasonically cleaned twice in ultrapure water, and finally washed with absolute ethanol and dried. Put the cleaned sample into the cage sampling device, and put the combination into the GD-MS needle sample cell for analysis after vacuuming. The optimized discharge voltage: 2.5 kV, discharge current: 3.0 mA, discharge gas (Ar) Flow rate: 1.0 cc / min. Then, the signal intensity of the elements in the sample was measured over time to further characterize the stability of the method. At the same time, the GD-MS signal intensity test was performed on the same sample by using the tantalum bath method as the data of the control group. Test results such as image 3 As shown, the results show that when the cage sample injection device with the size of 15 mm×5 mm×5 mm is used for analysis, good signal strength and discharge stabi...

Embodiment 2

[0050] The caged tantalum groove, tantalum groove, granular SiO 2 Dilute nitric acid (preferably 1:1 nitric acid (HNO 3 ) and ultrapure water), ultrasonically cleaned in ultrapure water, then ultrasonicated twice in ultrapure water, and finally washed with absolute ethanol and dried. Put the cleaned sample into the cage sampling device, and put the combination into the GD-MS needle sample cell for analysis after vacuuming. The optimized discharge voltage: 2.5 kV, discharge current: 3.0 mA, discharge gas (Ar) Flow rate: 1.0 cc / min. Then, the signal intensity of the elements in the sample was measured over time to further characterize the stability of the method. At the same time, the GD-MS signal intensity test was performed on the same sample by using the tantalum bath method as the data of the control group. Test results such as Figure 4 As shown, the results show that when the cage sample injection device with the size of 15 mm×5 mm×5 mm is used for analysis, good signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com