Bone defect implant, construction method thereof, preparation method thereof, computer readable storage medium and equipment

A construction method and bone defect technology, applied in bone implants, joint implants, joint implants, etc., can solve the problems of drug-resistant bacteria tissue and organ damage, long treatment period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

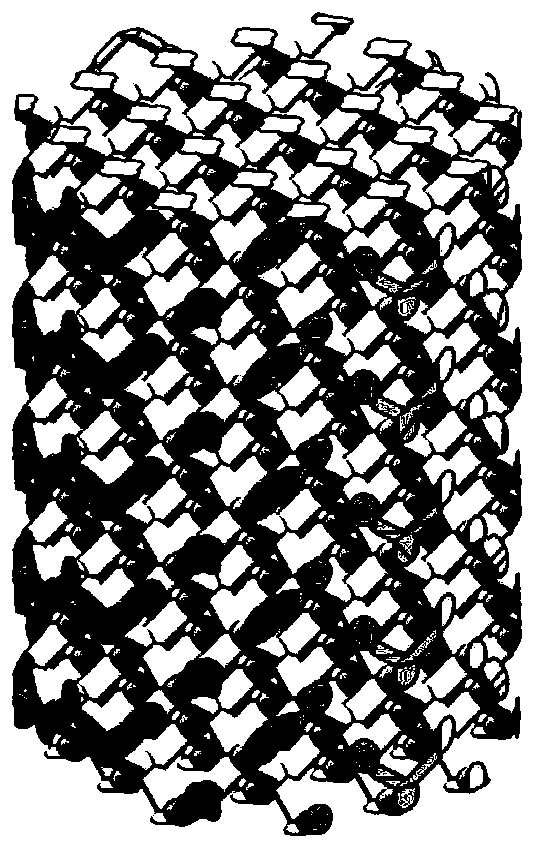

[0070] figure 1 It is the CT three-dimensional reconstruction diagram of this embodiment.

[0071] A bone defect implant, comprising a bone defect implant body, the contact surface of the bone defect implant body and bone is provided with a fusion surface layer, the fusion surface layer is a porous structure, and the porous structure is The layered structure of several layers, the layered structure of each layer has a plurality of micropores, the micropores of the layers are connected to each other, and has a regular hexahedral porous structure. The rate is 38.9%. The shape of the bone defect implant body and the fusion surface layer is the shape of the patient's bone defect. The material and mass percentage of the bone defect implant are: magnesium 95.5wt%, neodymium 3wt% , Zinc 1wt%, Zirconium 0.5wt%.

[0072] The compressive strength of the bone defect implant was 70MPa, and the elastic modulus was 1.3Gpa.

[0073] A method for preparing a bone defect implant, comprising...

Embodiment 2

[0084] A bone defect implant, comprising a bone defect implant body, the contact surface of the bone defect implant body and bone is provided with a fusion surface layer, the fusion surface layer is a porous structure, and the porous structure is The layered structure of several layers, the layered structure of each layer has multiple micropores, the micropores of the layers are connected to each other, and has a regular square porous structure. The rate is 75.3%. The shape of the bone defect implant body and the fusion surface layer is the shape of the patient's bone defect. The material and mass percentage of the bone defect implant are: magnesium 95.5wt%, neodymium 3wt% , Zinc 1wt%, Zirconium 0.5wt%.

[0085] The compressive strength of the bone defect implant was 34MPa, and the elastic modulus was 0.6Gpa.

[0086] A method for preparing a bone defect implant, comprising:

[0087] 1) Construct and obtain the bone defect implant model according to the construction method o...

Embodiment 3

[0097] A bone defect implant, including a bone defect implant body, the shape of the bone defect implant body is the shape of the patient's bone defect, the material and mass percentage of the bone defect implant: magnesium 96wt%, Neodymium 1wt%, Zinc 2wt%, Zirconium 1wt% (without fusion surface layer).

[0098] The compressive strength of the bone defect implant was 350MPa, and the elastic modulus was 40Gpa.

[0099] A method for preparing a bone defect implant, comprising:

[0100] 1) Construct and obtain the bone defect implant model according to the construction method of the bone defect implant model;

[0101] 11) Construct a three-dimensional bone model;

[0102] The three-dimensional bone model usually includes models of various tissues. For example, the model can include models of tissues such as skin, bones, blood vessels, nerves, and diseased parts (for example, tumors), and the model can reflect the individual (for example, patient) ), it can also reflect the sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com