Preparation method of alkali metal atom micro air chamber based on MEMS process

An alkali metal and gas chamber technology, applied in the field of MEMS, can solve problems such as complex manufacturing process, poor sealing, and poor signal-to-noise ratio, achieve smaller volume, eliminate residual stress and warping deformation, and avoid attenuation or damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

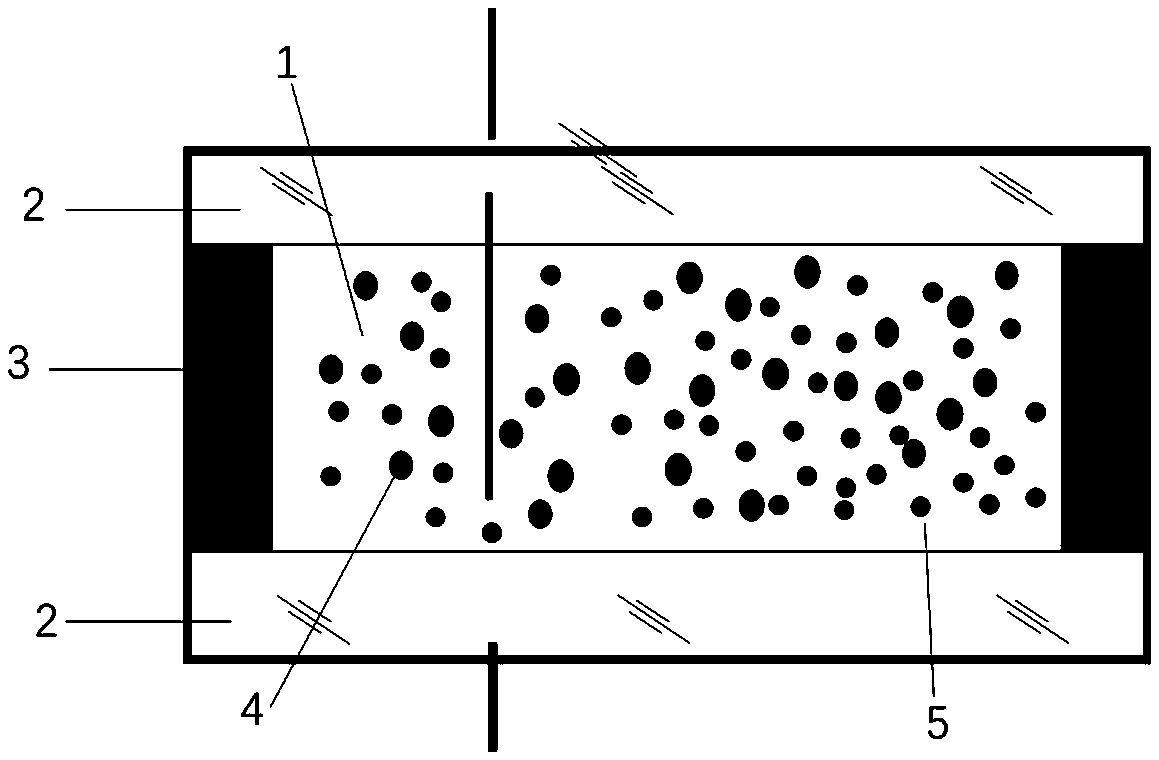

[0033] Due to the activity of alkali metal atoms, their simple substances are generally stored in glass containers, so the first choice for packaging materials is glass. Secondly, because it uses coherent beams to excite alkali metal atoms, the packaging of alkali metals must meet the following conditions:

[0034] (1) Alkali metal element must exist in the package cavity contents;

[0035] (2) The packaging cavity must be able to pass the light beam, and the light transmittance must be good;

[0036] (3) The packaging cavity must be able to withstand a certain temperature;

[0037] (4) The packaging material must not be magnetized;

[0038] (5) Packaging materials must meet the needs of MEMS processing and have a high surface cleanliness;

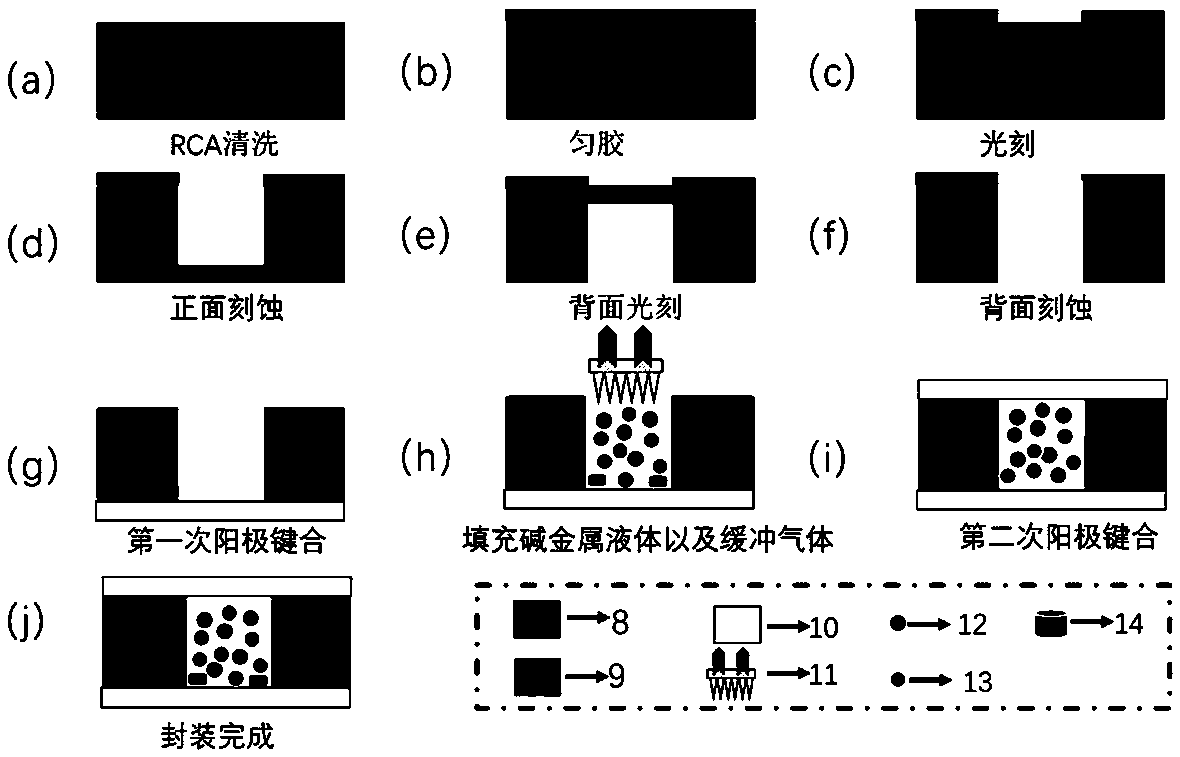

[0039]Therefore, in the present invention, a 4-inch P-type silicon wafer is selected as the structural material of the atomic gas chamber, and the thickness is 1.5 mm. Glass is generally used as a substrate or packaging component in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com