Membrane aeration aerobic granular sludge reactor, and method for culturing aerobic granular sludge and synchronously removing nitrogen and carbon of reactor

A technology of aerobic granular sludge and expanded granular sludge, which is applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sludge/sewage treatment, etc., to reduce aeration costs and high-efficiency oxygen mass transfer Rate, the effect of improving aeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

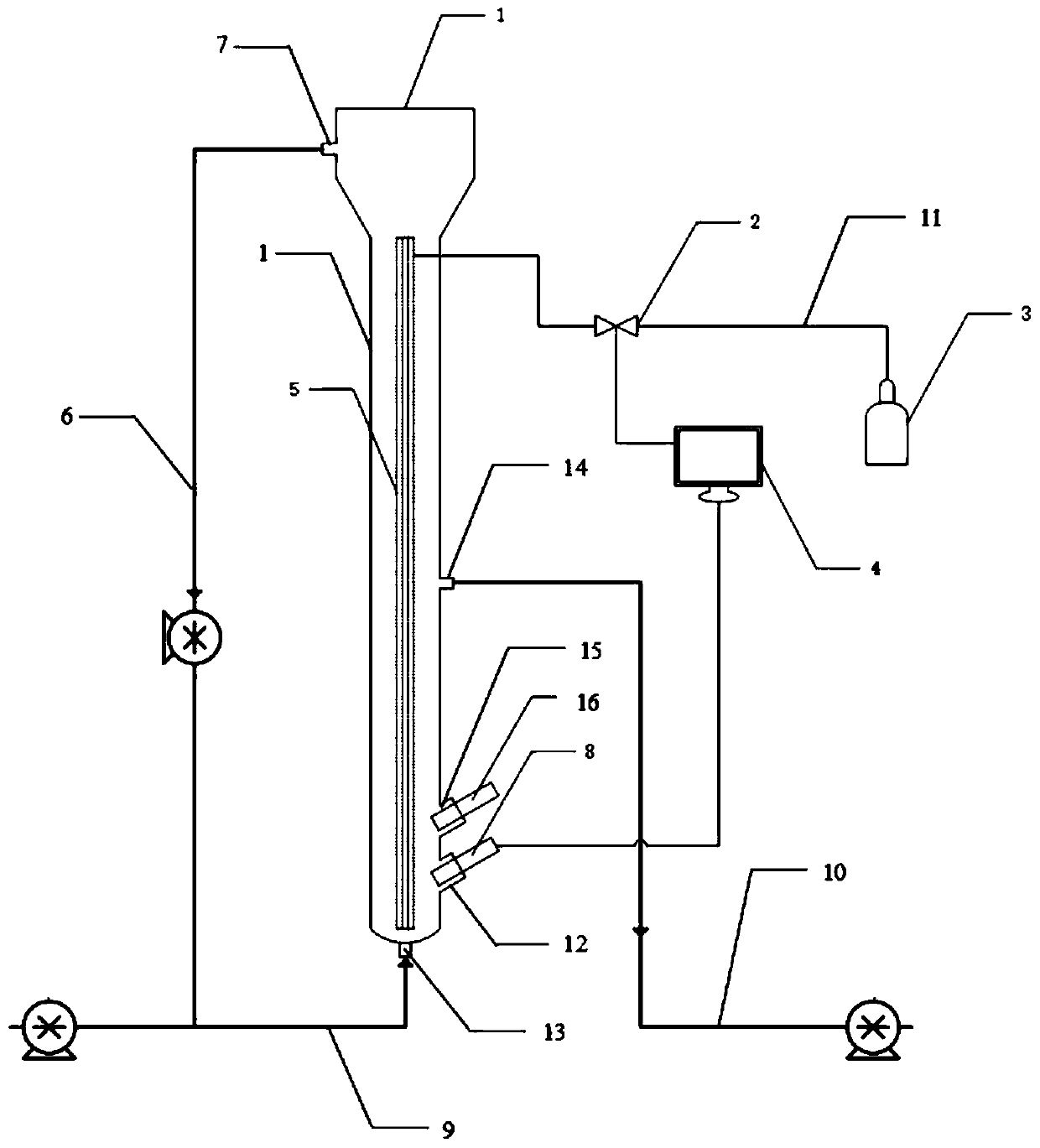

[0046] This embodiment provides a membrane aerated aerobic granular sludge reactor, which includes an expanded granular sludge bed reactor 1, a membrane aeration system, an online dissolved oxygen control system, Circulation bypass 6, water inlet pipeline 9 and water outlet pipeline 10; wherein: expanded granular sludge bed reactor 1 is used as a tank body for cultivating aerobic granular sludge;

[0047] The expanded granular sludge bed reactor 1 includes a lower reaction zone and an upper solid-liquid separation zone. The upper solid-liquid separation zone is formed by increasing the inner diameter of the top of the lower reaction zone; the expanded granular sludge bed reactor 1 is equipped with a circulation outlet The water outlet 7, the water outlet 14 and the water inlet 13, the circulating water outlet 7, the water outlet 14 and the water inlet 13 are sequentially arranged at the upper, middle and bottom of the expanded granular sludge bed reactor 1; the circulating wate...

Embodiment 2

[0059] This embodiment provides a method for cultivating aerobic granular sludge using the membrane aerated aerobic granular sludge reactor of Example 1. The method is implemented according to the following steps:

[0060] 1. Inoculate the activated sludge into the expanded granular sludge bed reactor 1.

[0061] 2. Inject sewage or waste water into the expanded granular sludge bed reactor 1 from the water inlet 13 through the water inlet pump, so that the water level of the sewage or waste water reaches or is higher than the circulating water outlet 7. After the water intake is completed, start the circulating pump to make the sewage Or the waste water flows into the circulation bypass 6 from the circulation outlet 7 under the drive of the circulation pump and flows back to the inside of the expanded granular sludge bed reactor 1 through the water inlet 13, and then flows up in the expanded granular sludge bed reactor 1, Then flow into the circulating bypass 6 from the circul...

Embodiment 3

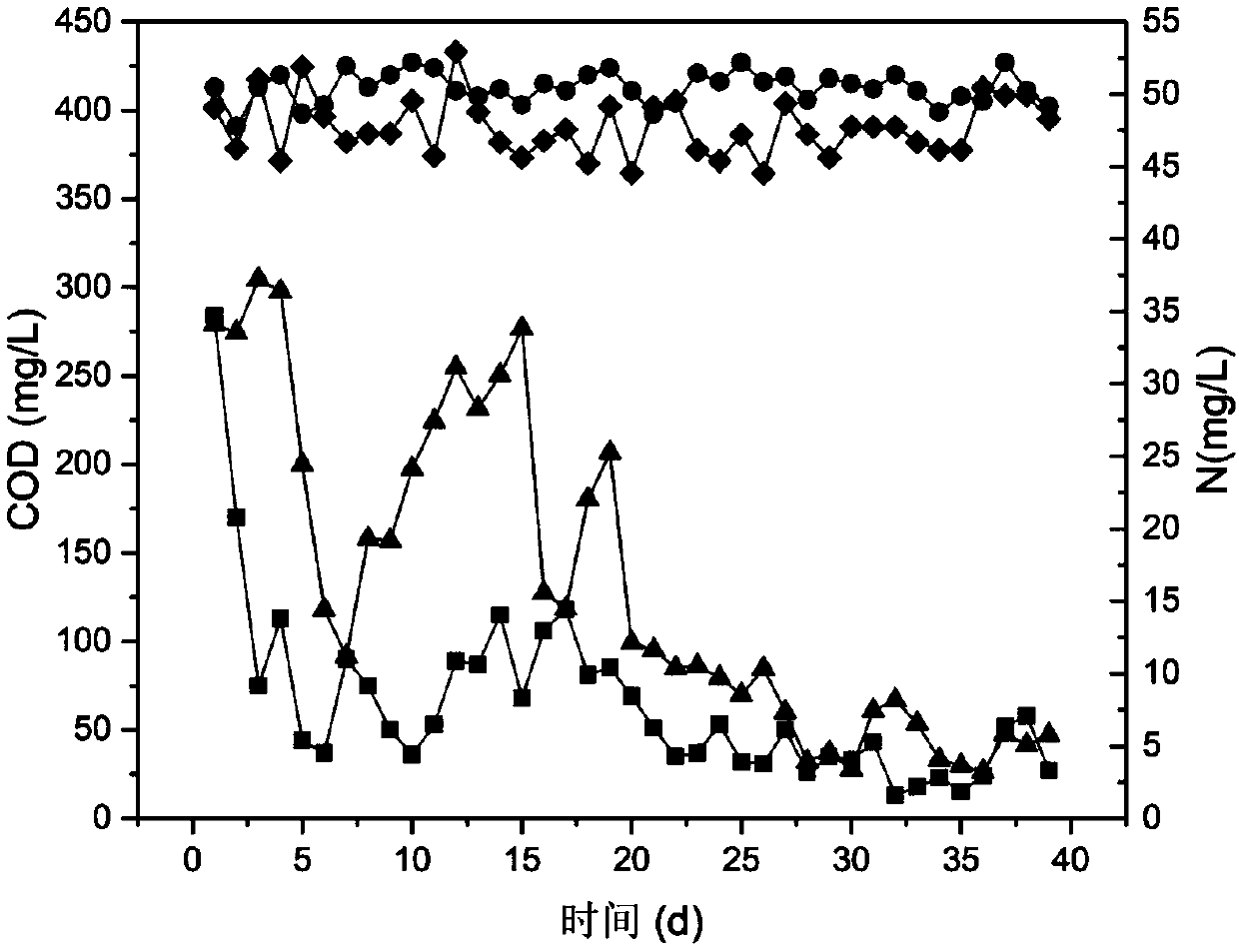

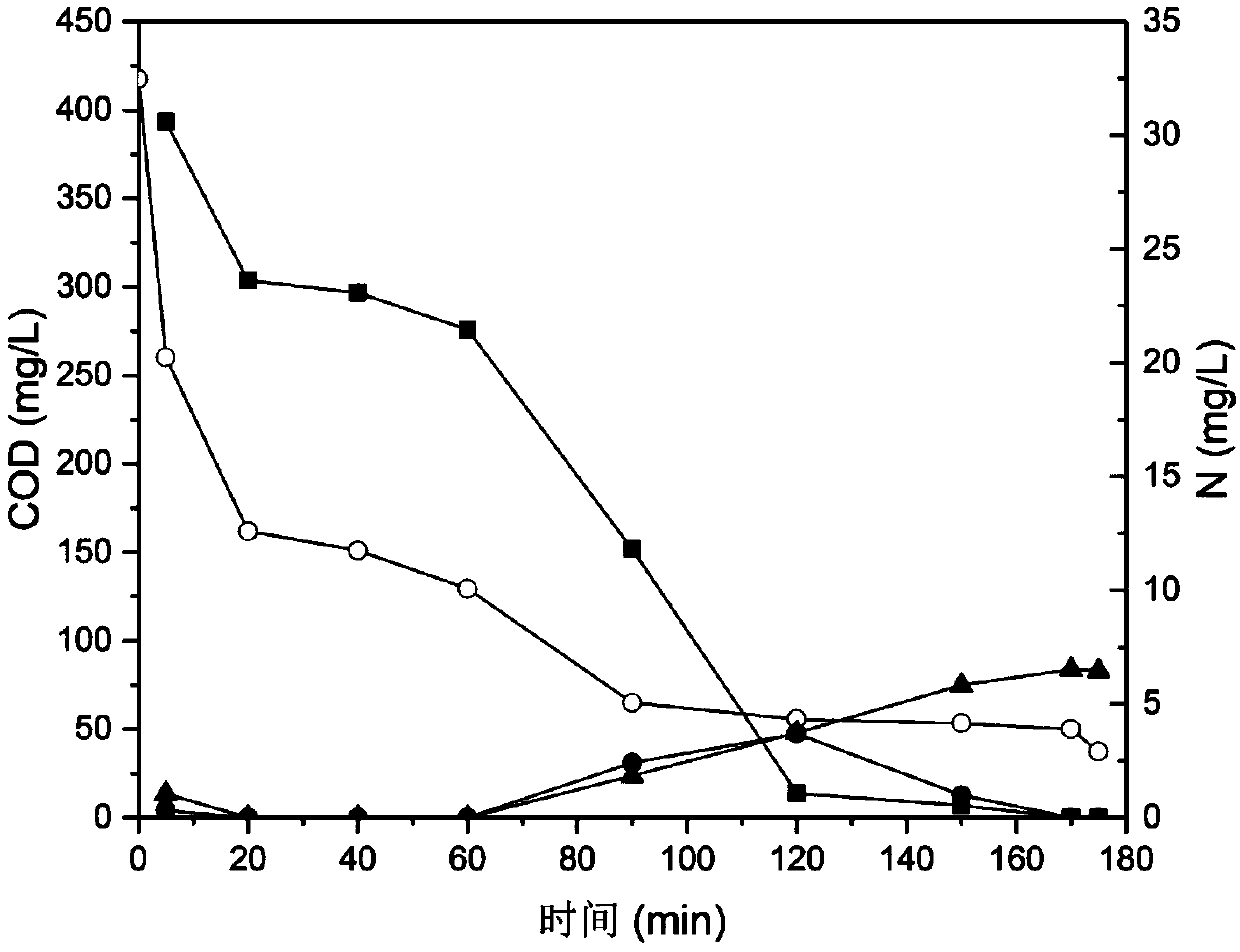

[0068] This embodiment provides a sewage treatment method, specifically using the membrane aerated aerobic granular sludge reactor in Example 1 and the mature aerobic granular sludge cultivated according to the method in Example 2 to synchronize sewage or wastewater A method for denitrification and carbon removal, the method is to inject the sewage or waste water to be treated into the expanded granular sludge bed reactor 1 until the water level of the treated sewage or waste water reaches or is higher than the circulating water outlet 7, and the water body is circulated through the circulating pump Circulating flow in the expanded granular sludge bed reactor 1 and the circulation bypass 6, control the rising flow rate of the water body in the expanded granular sludge bed reactor 1 to 0.10m / min~0.25m / min, and operate under the condition of no aeration Complete the anaerobic stage operation in 60 minutes; continue to keep the circulation pump running to ensure that the water bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com