Compound, display panel and electronic equipment

A compound and an independent technology, applied in the field of organic electroluminescent materials, can solve the problems of unfavorable large-scale production, efficiency roll-off, and low production cost, so as to improve luminous efficiency and working life, improve luminous efficiency, and increase the strength of the oscillator Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

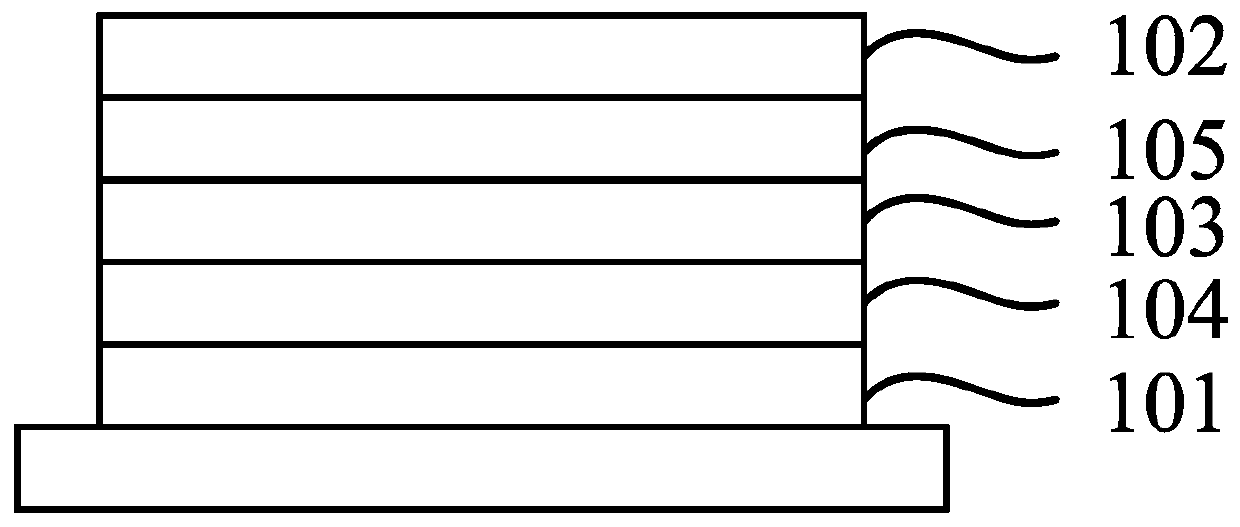

Image

Examples

Embodiment 1

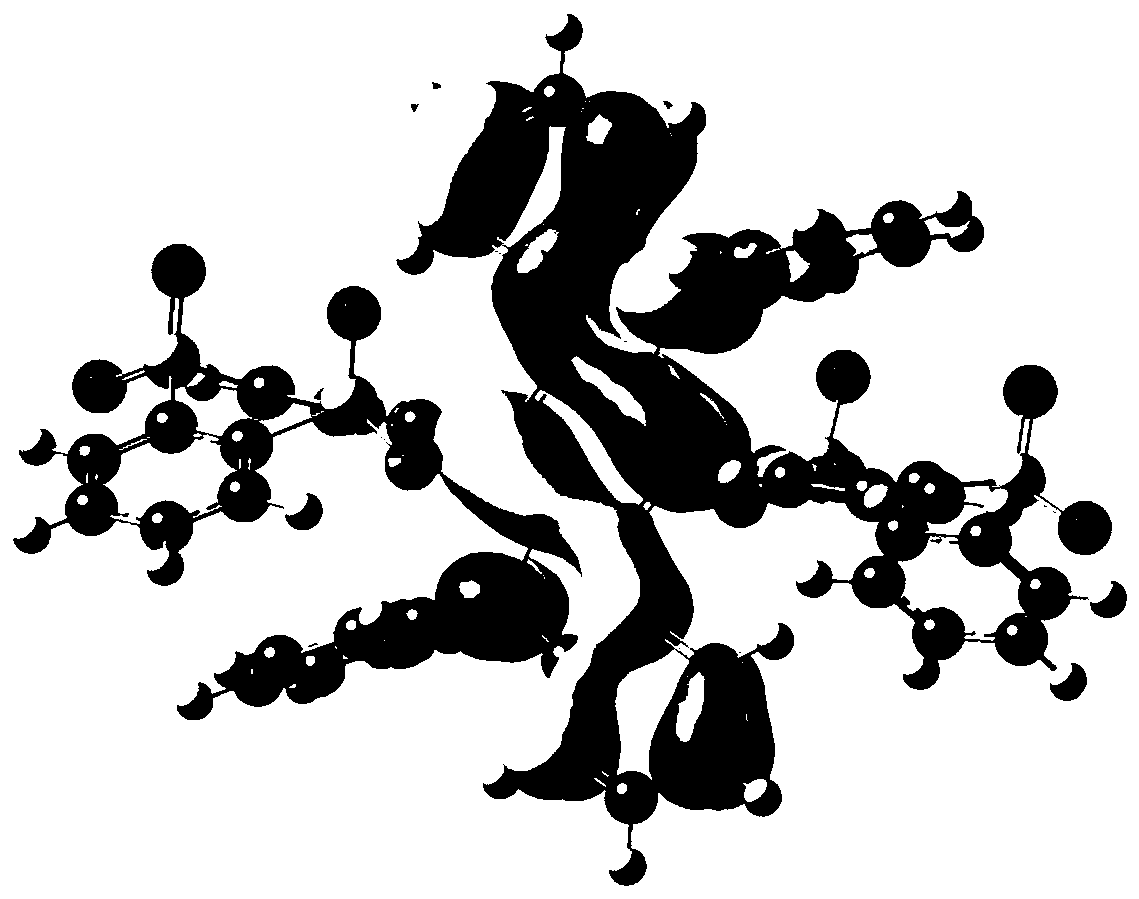

[0160] This embodiment provides a compound with the following structure:

[0161]

[0162] Its preparation method comprises the following steps:

[0163]

[0164] Under nitrogen protection, compound S1 (1.5mmol), S2 (3.2mmol), [Pd 2 (dba) 3 ]·CHCl 3 (0.05mmol) and HP(tBu) 3 ·BF 4 (0.1mmol) was added into a 100mL two-necked flask, and 30mL of toluene was injected into the two-necked flask (through N 2 15min deoxygenation), and then add 2.5mL concentration of 1M K 2 CO 3 Aqueous solution (pass N in advance 2 15min deoxygenation), stirring overnight at room temperature; after the reaction, add 20mL deionized water, and then drop a few drops of 2M HCl; extract with dichloromethane, collect the organic phase, and wash with anhydrous Na 2 SO 4 Dry processing. The dried solution was filtered, and the solvent was removed by a rotary evaporator to obtain a crude product. The crude product was purified by silica gel chromatography, and finally the intermediate product ...

Embodiment 2

[0171] This embodiment provides a compound with the following structure:

[0172]

[0173] Its preparation method comprises the following steps:

[0174]

[0175] Under the condition of -78°C, S1 (1.8mmol) was dissolved in ether (100mL), and n-BuLi (3.9mmol) n-hexane solution was added dropwise into the solution; the reaction solution was continuously stirred for 2h, and slowly heated to room temperature, stirred at room temperature for 1 h. The reaction solution was cooled to -78°C again, and 90 mL of S5 (3.8 mmol) in toluene was added dropwise with stirring; the temperature was slowly raised to room temperature and stirred overnight. All the solvent was distilled off under reduced pressure, and the crude product was collected. The crude product was washed with methanol (3 x 40 mL) and pentane (3 x 40 mL), respectively, and the crude product was collected again. The crude product was purified by silica gel chromatography, using a mixed solvent of n-hexane and chlorof...

Embodiment 3

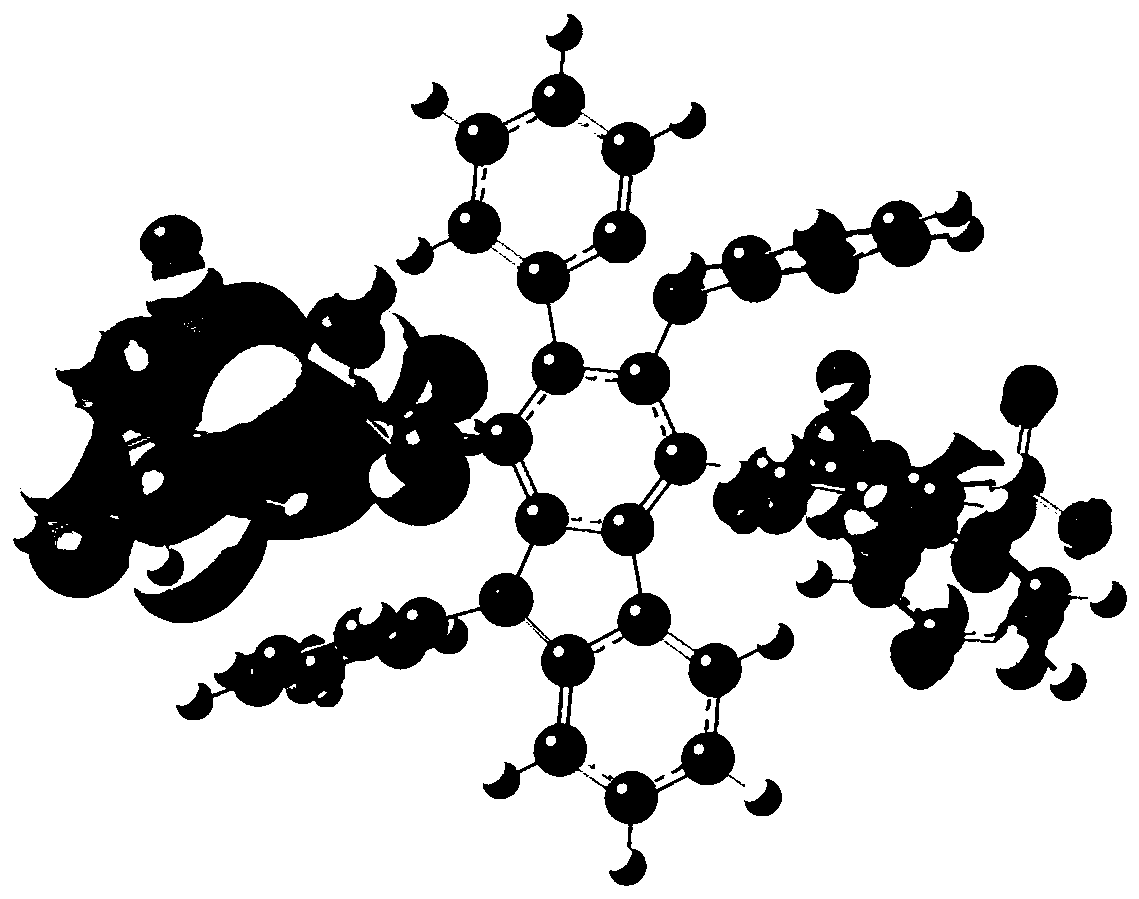

[0182] This embodiment provides a compound with the following structure:

[0183]

[0184] Its preparation method comprises the following steps:

[0185]

[0186] Under nitrogen protection, compound S1 (2.25mmol), S7 (4.8mmol), [Pd 2(dba) 3 ]·CHCl 3 (0.1mmol) and HP(tBu) 3 ·BF 4 (0.2mmol) was added into a 250mL two-necked flask; 60mL of toluene was injected into the two-necked flask (passed N in advance 2 15min deoxygenation), and then added dropwise 4mL concentration of 1M K 2 CO 3 Aqueous solution (pass N in advance 2 15min deoxygenation), stirred overnight at room temperature; after the reaction, add 35mL deionized water, and then drop a few drops of 2M HCl; extract with dichloromethane, collect the organic phase, and wash with anhydrous Na 2 SO 4 Dry processing. The dried solution was filtered, and the solvent was removed by a rotary evaporator to obtain a crude product. The crude product was purified by silica gel chromatography, and finally the interme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com