Inorganic nanomaterial toughened HDPE (high-density polyethylene) double-wall corrugated pipe composite masterbatch and preparation method thereof

A technology of inorganic nanomaterials and double-wall corrugated pipes, applied in the field of inorganic toughening composite masterbatch for high-density polyethylene HDPE double-wall corrugated pipes, can solve the problems of ring stiffness decrease, toughness improvement, toughness non-conformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

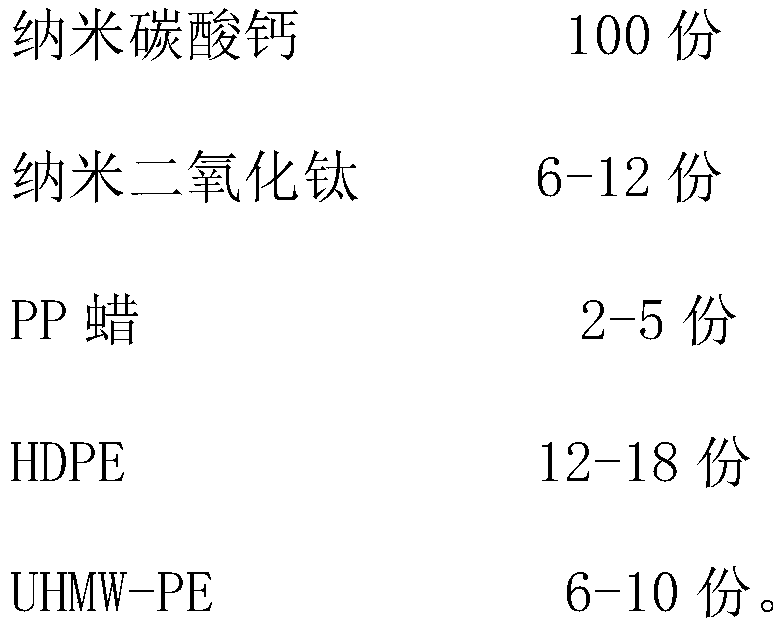

[0015] A preparation method of an inorganic nanomaterial toughened HDPE double-wall corrugated pipe composite masterbatch, comprising the following components in parts by weight:

[0016]

[0017] The preparation method adopted:

[0018] (1) The above-mentioned nano-calcium carbonate, nano-titanium dioxide, maleic anhydride grafted HDPE, ultra-high molecular weight polyethylene UHMW-PE, and maleic anhydride grafted PP wax. Add it into the tunnel microwave dryer according to the proportion of the components, and preheat the microwave drying for 6 minutes to become dry premixed powder.

[0019] (2) Feed the dry pre-mixed powder into the double-rotor continuous internal mixer through automatic metering and automatic suction. High speed, high shear, kneading, plasticizing, melting, exhaust. Enter the single-screw extruder, the single-screw mandrel is equipped with circulating water cooling device. Extrude compact compression molding, grind the surface eagerly, and obtain the...

Embodiment 2

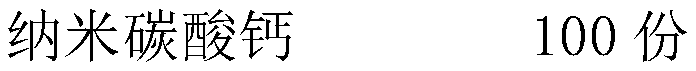

[0021] A preparation method of an inorganic nanomaterial toughened HDPE double-wall corrugated pipe composite masterbatch, comprising the following components in parts by weight:

[0022]

[0023] The preparation method adopted:

[0024] (1) The above-mentioned nano-calcium carbonate, nano-titanium dioxide, maleic anhydride grafted HDPE, ultra-high molecular weight polyethylene UHMW-PE, and maleic anhydride grafted PP wax. Add it into the tunnel microwave dryer according to the proportion of the components, and preheat for 8 minutes for microwave drying to become dry premixed powder.

[0025] (2) Feed the dry pre-mixed powder into the double-rotor continuous internal mixer through automatic metering and automatic suction. High speed, high shear, kneading, plasticizing, melting, exhaust. Enter the single-screw extruder, the single-screw mandrel is equipped with circulating water cooling device. Extrude compact compression molding, grind the surface eagerly, and obtain the...

Embodiment 3

[0027] A preparation method of an inorganic nanomaterial toughened HDPE double-wall corrugated pipe composite masterbatch, comprising the following components in parts by weight:

[0028]

[0029] The preparation method adopted:

[0030] (1) The above-mentioned nano-calcium carbonate, nano-titanium dioxide, maleic anhydride grafted HDPE, ultra-high molecular weight polyethylene UHMW-PE, and maleic anhydride grafted PP wax. Add it into the tunnel microwave dryer according to the proportion of the components, and preheat it for 10 minutes for microwave drying to become dry premixed powder.

[0031] (2) Feed the dry pre-mixed powder into the double-rotor continuous internal mixer through automatic metering and automatic suction. High speed, high shear, kneading, plasticizing, melting, exhaust. Enter the single-screw extruder, the single-screw mandrel is equipped with circulating water cooling device. Extrude compact compression molding, grind the surface eagerly, and obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com