Composite electrode material, as well as preparation method and application thereof

A composite electrode and mixed solution technology, applied in electrolytic inorganic material coating, electrode, nanotechnology for materials and surface science, etc., can solve problems such as obstruction and photocorrosion, achieve short diffusion length, low recombination rate, The effect of a large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

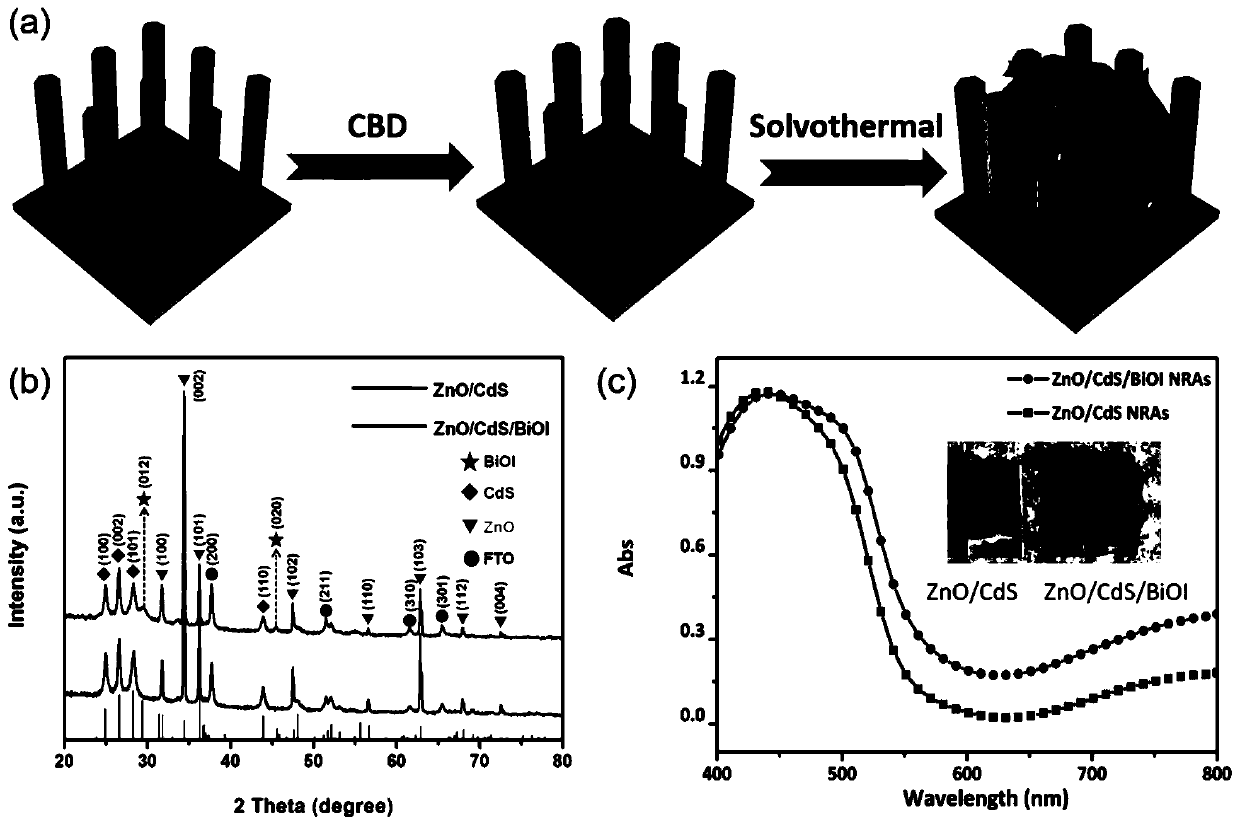

[0049] A composite electrode material, the composite electrode material is a 3D crosslinked heterostructure ZnO / CdS / BiOI nanorod array, the 3D crosslinked heterostructure ZnO / CdS / BiOI nanorod array is uniformly arranged vertically A one-dimensional ZnO / CdS nanorod array combined with BiOI nanosheets. The ZnO / CdS nanorod array is formed by uniformly dispersing CdS on the surface of the ZnO nanorod array. The molar ratio of ZnO, CdS, and BiOI in the composite electrode material is It is 34:138:1.

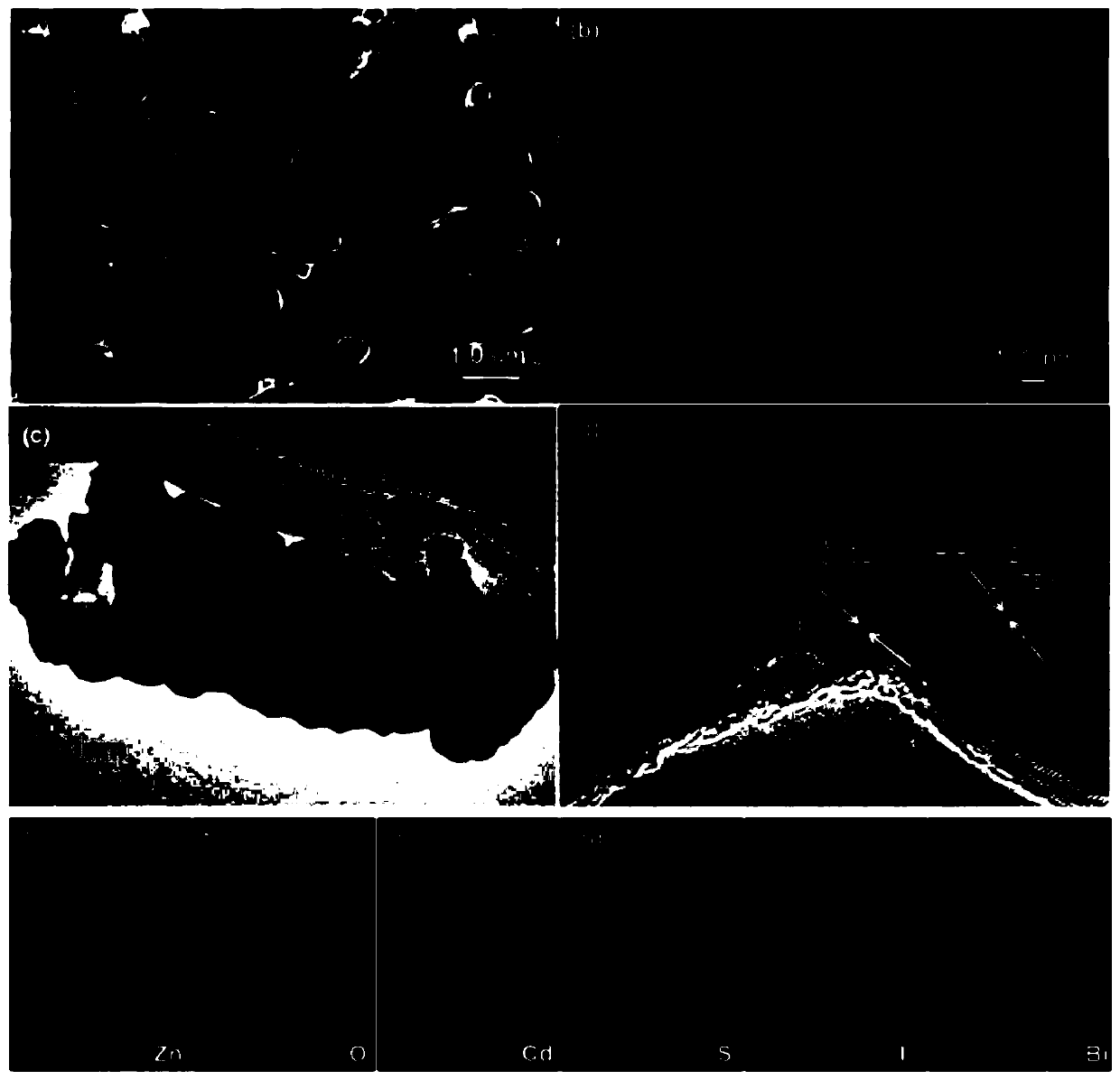

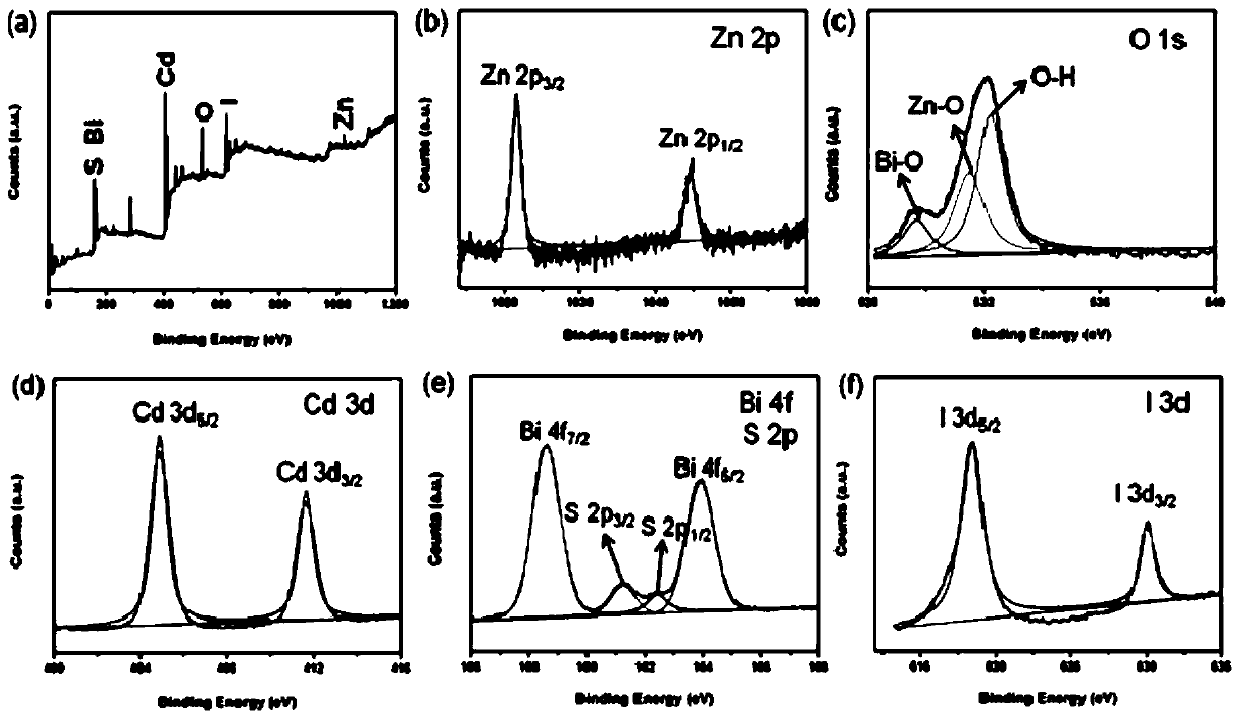

[0050] The synthesis steps and mechanism of composite electrode material of the present invention are as figure 1 As shown in (a), ZnO thin films were first prepared on conductive glass (FTO) substrates by electrodeposition, and then dispersed on the surface of ZnO nanorod arrays (NRAs) by CdS to form ZnO / CdS NRAs, and then introduced by solvothermal method BiOI nanosheets, and the separated ZnO / CdS NRAs are connected to each other by many vertically aligned BiOI ultrathin nanosheets...

Embodiment 2

[0058] A composite electrode material, the composite electrode material is a 3D crosslinked heterostructure ZnO / CdS / BiOI nanorod array, the 3D crosslinked heterostructure ZnO / CdS / BiOI nanorod array is uniformly arranged vertically A one-dimensional ZnO / CdS nanorod array combined with BiOI nanosheets. The ZnO / CdS nanorod array is formed by uniformly dispersing CdS on the surface of the ZnO nanorod array. The molar ratio of ZnO, CdS, and BiOI in the composite electrode material is It is 17:69:1.

[0059] The preparation method of the composite electrode material of the present embodiment comprises the following steps:

[0060] (1) Preparation of ZnO nanorod array: Weigh 2.97g zinc nitrate, 0.385g ammonium acetate and 0.701g hexamethylenetetramine, pour them into a 200mL beaker, put a stirring bar in the beaker, add deionized water, Stir magnetically until the solid is completely dissolved, transfer the solution to a 500mL volumetric flask, and constant volume to configure a ZnO...

Embodiment 3

[0066] A composite electrode material, the composite electrode material is a 3D crosslinked heterostructure ZnO / CdS / BiOI nanorod array, the 3D crosslinked heterostructure ZnO / CdS / BiOI nanorod array is uniformly arranged vertically A one-dimensional ZnO / CdS nanorod array combined with BiOI nanosheets. The ZnO / CdS nanorod array is formed by uniformly dispersing CdS on the surface of the ZnO nanorod array. The molar ratio of ZnO, CdS, and BiOI in the composite electrode material is It is 9:35:1.

[0067] The preparation method of the composite electrode material of the present embodiment comprises the following steps:

[0068] (1) Preparation of ZnO nanorod array: Weigh 2.97g zinc nitrate, 0.385g ammonium acetate and 0.701g hexamethylenetetramine, pour them into a 200mL beaker, put a stirring bar in the beaker, add deionized water, Stir magnetically until the solid is completely dissolved, transfer the solution to a 500mL volumetric flask, and constant volume to configure a ZnO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com