A kind of preparation method of ultra-thin heat pipe

An ultra-thin heat pipe and heat pipe technology, applied in the field of heat pipes, can solve the problems of not being suitable for mass production or effective application, difficult to process liquid absorbing cores, low manufacturing efficiency, etc., achieving good infiltration and reflux characteristics, and increasing apparent specific area. , to achieve the effect of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of ultra-thin copper heat pipe with a thickness of 0.2mm:

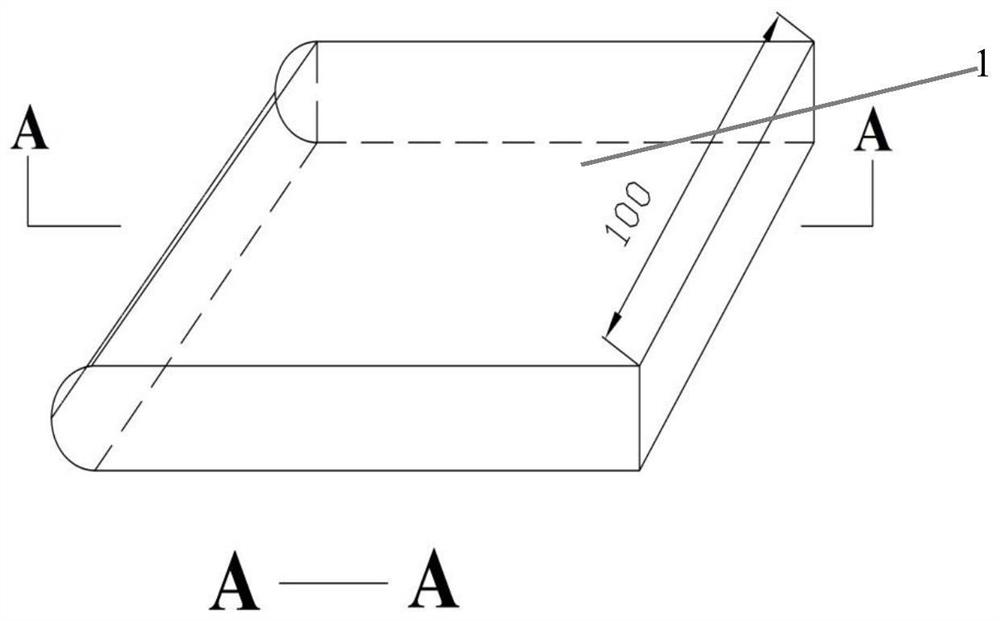

[0045]Step (1): 1. select heat pipe 1 material to be copper, design heat pipe 1 as (such as figure 1 Shown) the shape shown, its size is 100×100×0.2mm ( figure 1 Middle A-A);

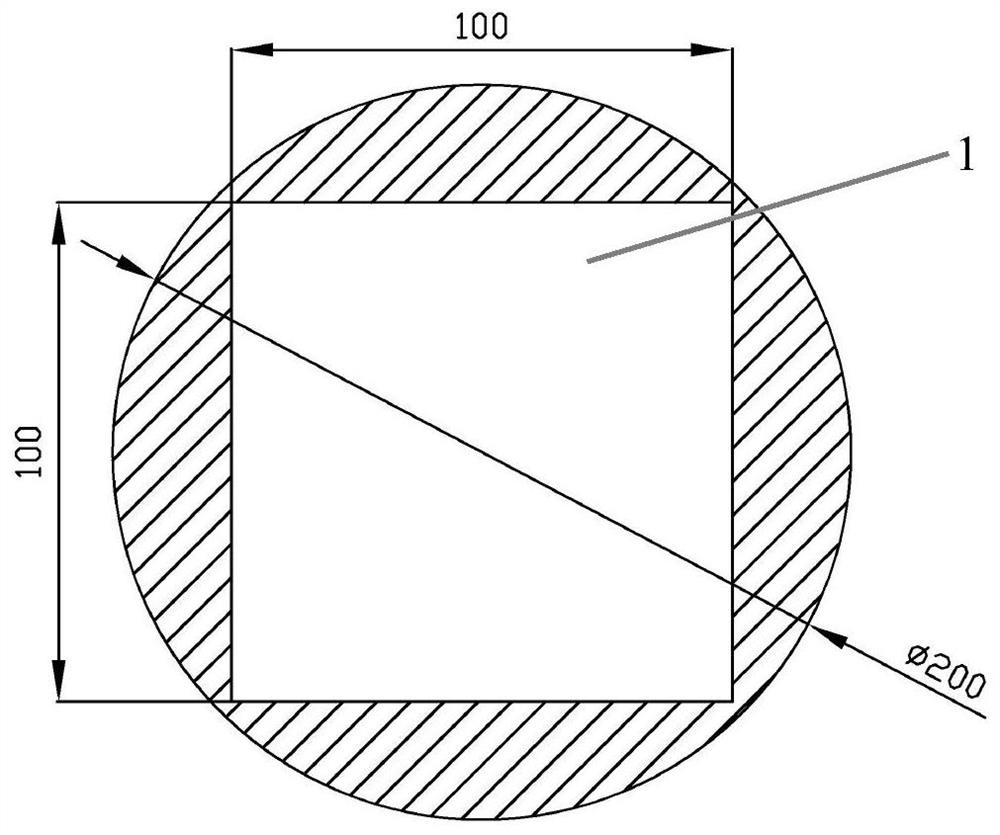

[0046] ②According to the material, size and surface profile of heat pipe 1, select the mold electrode to be processed as titanium alloy, and the surface profile diameter is Φ200mm. figure 2 As shown) a rectangular area with an area of 120×120mm is drawn in the outline as the outline structure processing area;

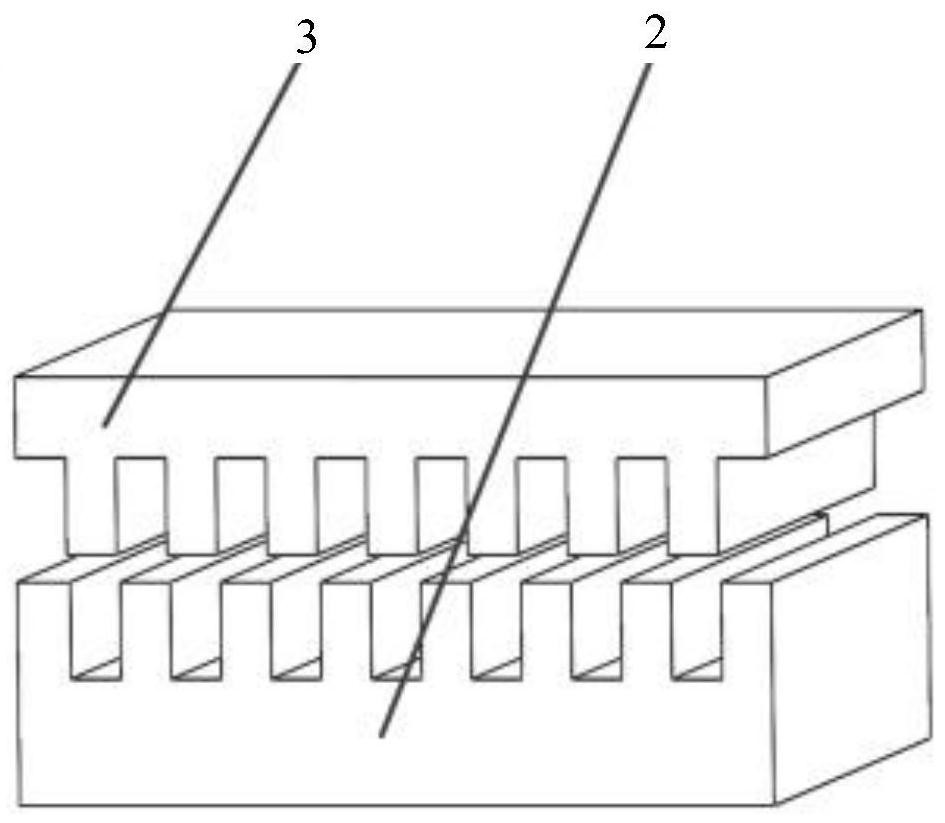

[0047] ③ According to the designed inner surface structure of the heat pipe 1, the surface microstructure of the mold electrode 2 is designed to be microgrooves with a width of 60 μm, a depth of 30 μm, and an interval of 60 μm.

[0048] ④According to step ②, the titanium rod is processed into a Φ200×300mm block electrode by machining technology, and the Φ200mm surface is the electrode processing surface;

[0049...

Embodiment 2

[0056] Prepare an ultra-thin nickel heat pipe with a thickness of 0.2mm. The preparation method is the same as in Example 1, except that 350g of nickel sulfamate, 10g of nickel chloride, 35g of boric acid and deionized water are completely mixed to prepare a 1000mL electric tube. Cast salt solution.

[0057] The process in the present invention can use different electrodes and electroforming solutions to prepare heat pipes of different materials such as iron and nickel on the same equipment, and the process has strong flexibility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com