Electron beam photoetching method based on metal-doped Te-based phase change material

A technology of electron beam lithography and metal doping, applied in the field of lithography, can solve the problems of unfriendly environment, toxicity, complicated photoresist preparation process, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides an electron beam photoresist application and an electron beam lithography method based on a metal-doped Te-based phase change material, the steps of which include:

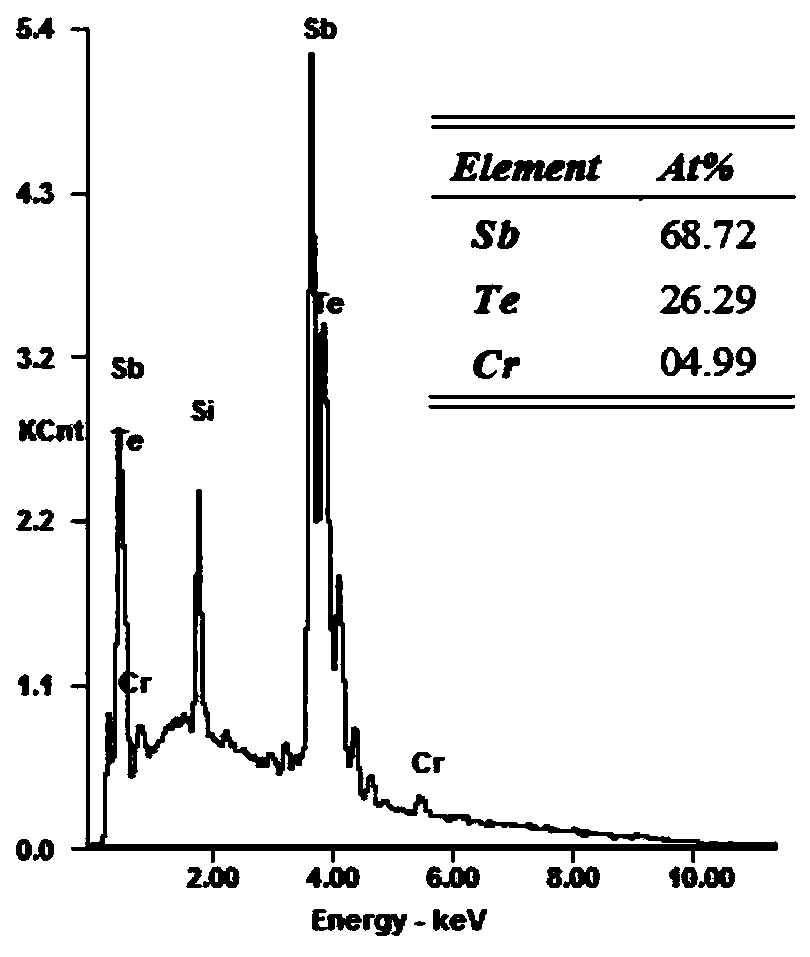

[0031] 1) Plating a layer of 100nm thick Cr-doped Sb on quartz glass by double-target magnetron co-sputtering method 2 Te film, where the background vacuum is 4×10 -4 Pa, Cr target using DC sputtering, sputtering power 4W, Sb 2 The Te target is sputtered by radio frequency, the sputtering power is 80W, the sputtering pressure is 0.5Pa, and the sputtering time is 5min; the composition of the prepared film is as follows: figure 1 Shown in the EDS result; The surface morphology of the prepared film is as follows figure 2 The SEM results are shown.

[0032] 2) Use electron beam exposure system to carry out photolithography on the above-mentioned coating samples, the acceleration voltage of the electron beam used is 10kV, the electron beam current is 1nA, and the exposure dose is 100...

Embodiment 2~4

[0034] The printing steps of Examples 2-4 are the same as those of Example 1, and the parameters of the coated samples and the photolithography parameters are shown in the table below.

[0035]

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com