Silver-manganese bimetal composite catalyst for oxygen reduction reaction in alkaline medium and synthesis method thereof

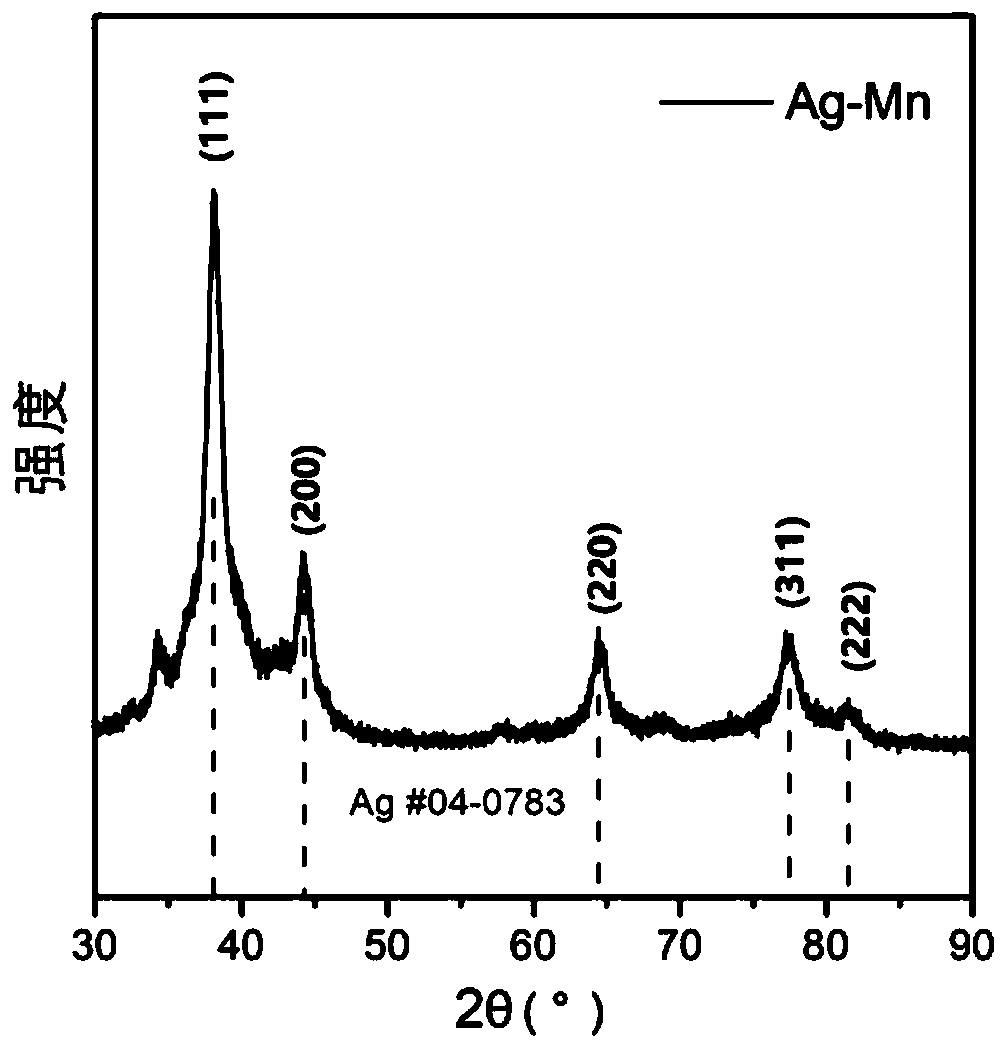

A technology of composite catalyst and alkaline medium, which is applied in the direction of electrical components, structural parts, battery electrodes, etc., can solve the problems of low electrocatalytic activity of oxygen reduction and low electrochemical stability, and achieve simple operation, uniform particle size distribution, The effect of improving electrocatalytic performance and electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also proposes a synthesis method of the above-mentioned composite catalyst, comprising the following steps: forming a precursor solution containing silver source and manganese source; heating the precursor solution to 180°C-240°C and maintaining it for 0.5-4 hours to form a dispersed The reaction solution of the composite catalyst; separating and purifying the reaction solution to obtain composite catalyst nanoparticles. The composite catalyst particles obtained by separation and purification are further supported on the carrier material to obtain the composite catalyst material applied in the alkaline fuel cell. The inert atmosphere is one or a mixture of nitrogen, argon, and helium.

[0032] In some embodiments, a source of silver and a source of manganese are dissolved in a solvent to form a precursor solution. Solvents include organic and aqueous phases. Preferably, the solvent is an amine organic phase. More preferably, the solvent includes...

Embodiment 1

[0041] A preparation method of silver-manganese composite catalyst, comprising the steps of:

[0042]1. Take 110mg AgNO 3 and 20 μl of 50wt% manganese nitrate solution were dissolved in 10ml oleylamine, then the solution was added to a 50ml three-necked flask, and N was introduced at room temperature 2 , lasted 30min, to remove dissolved oxygen in oleylamine. It was then heated to 220° C. for 1 hour.

[0043] 2. Add 30ml (volume ratio 1:1) isopropanol and ethanol to the oleylamine after the reaction, centrifuge at 10000rpm for 3min. Pour off the supernatant, redisperse and dissolve the precipitate in 30ml (volume ratio 1:1) isopropanol and ethanol, repeat the above centrifugation process once. The resulting precipitate was redispersed and stored in 30 ml cyclohexane.

[0044] 3. Add 150mg of activated carbon powder (Vulcan XC-72) into 150ml of cyclohexane and ultrasonically disperse for 30min. The silver-manganese metal nanoparticles prepared in step 2 were added dropwise...

Embodiment 2

[0049] A preparation method of silver-manganese composite catalyst, comprising the steps of:

[0050] 1. Dissolve 134mg of silver acetylacetonate and 20 μl of 50wt% manganese nitrate solution in 10ml of oleylamine, then add the solution to a 50ml three-necked flask, and feed N under room temperature. 2 , lasted 30min, to remove dissolved oxygen in oleylamine. It was then heated to 220° C. for 1 hour.

[0051] Other synthesis and testing steps are the same as in Example 1.

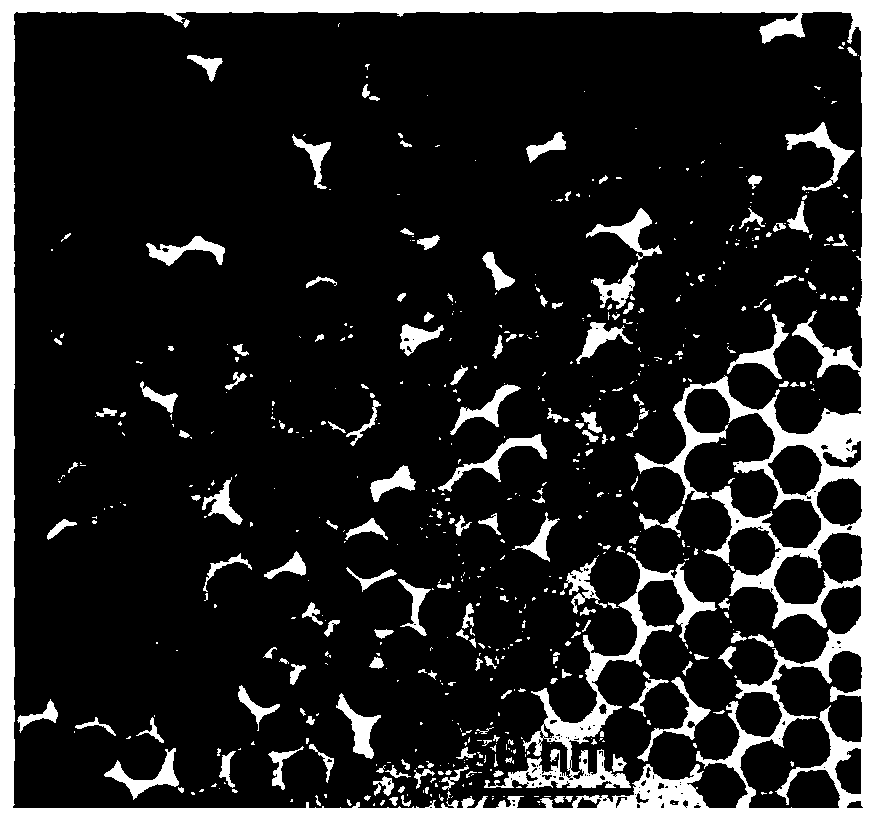

[0052] The prepared carbon-supported metal catalyst is marked as Ag-Mn-2. Characterized as image 3 As shown, the distribution of Ag-Mn-2 nanoparticles is uniform, and the particle size is about 9nm. According to the results of ICP-ACE, the atomic proportions of silver and manganese are 89at% and 11at%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com