Melting and cocrystallization method of erythritol and high-power sweetening agent and product obtained by melting and cocrystallization method

A technology of high-intensity sweetener and erythritol, which is applied in the field of melt co-crystallization of erythritol and high-intensity sweetener, can solve the problem of bitterness and pungent taste, and does not involve the yield of co-crystal products and the feeling of sweetness. Not obvious and other problems, to achieve the effect of reducing production cost, low cost, and not easy to stick to the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

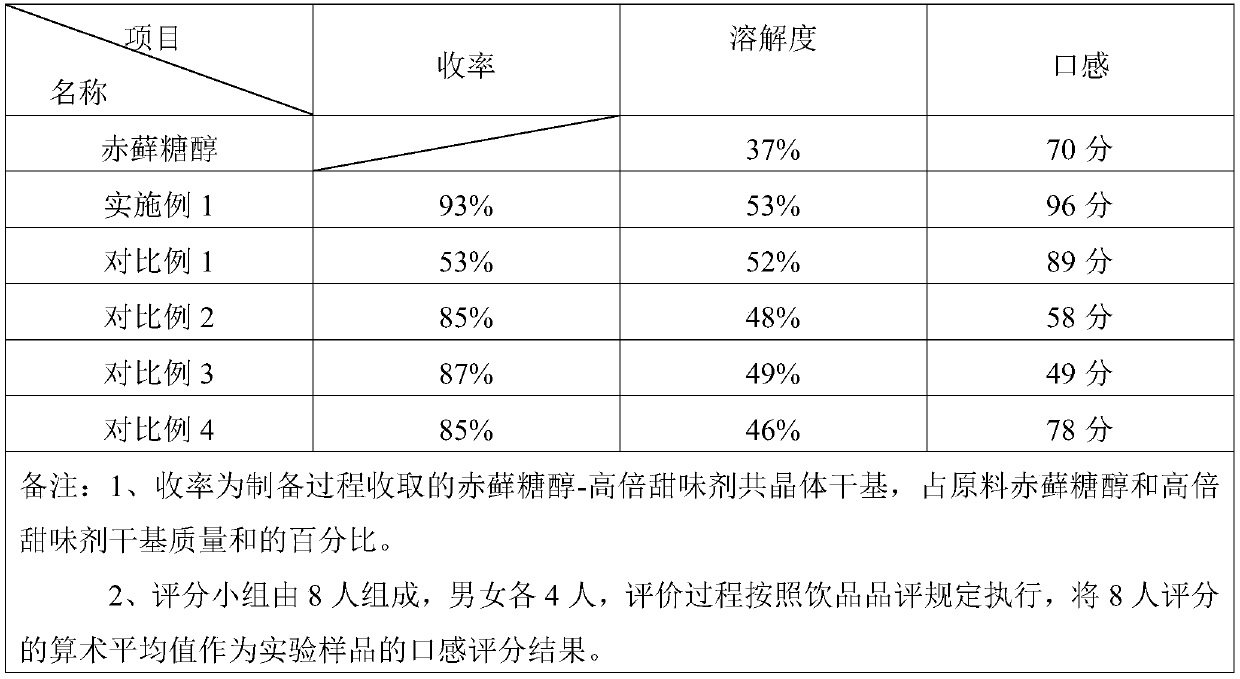

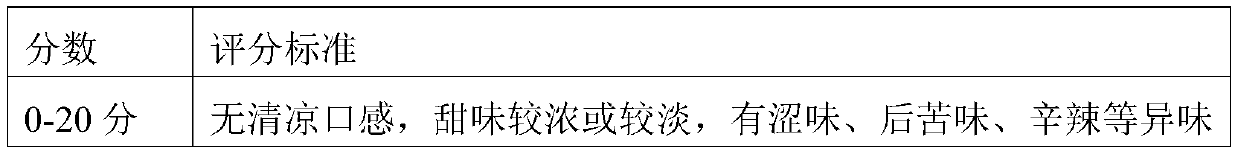

Examples

Embodiment 1

[0044] A method for melting co-crystallization of erythritol and high-intensity sweeteners, comprising steps as follows:

[0045] (1) Put erythritol crystals into the crystallization equipment and heat up to 148°C; after the erythritol crystals are completely dissolved, cool down to 117°C and keep warm for 30 minutes to prepare an erythritol solution;

[0046] (2) Make a suspension with high-intensity sweetener and water at a mass ratio of 1:2, then stir at 90-95°C until dissolved, then slowly add 1% of the mass of erythritol to the crystallization equipment , making erythritol-high-intensity sweetener mixed solution;

[0047] (3) Stir the erythritol-high-intensity sweetener mixture prepared in step (2) at a rate of 25°C and 300r / min for 30min, and then cool the melting and crystallization equipment to 105°C at a rate of 0.5°C / min. °C, and then rapidly cooled to 70 °C at a rate of 5 °C per minute to prepare erythritol-high-intensity sweetener co-crystals.

[0048] The high-int...

Embodiment 2

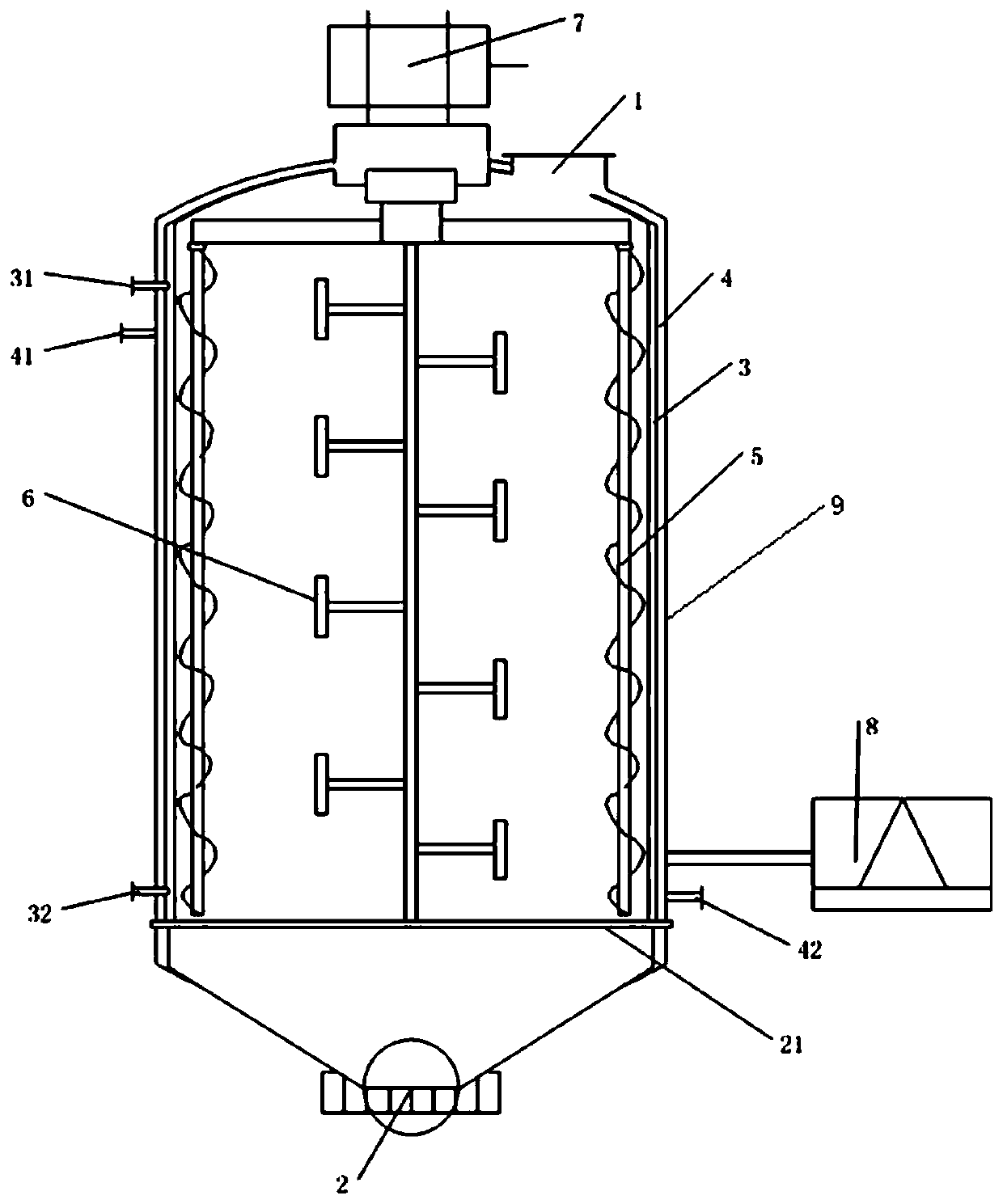

[0050] Such as figure 1 As shown, a kind of equipment of melting co-crystallization of erythritol and high power sweetener, described melting crystallization equipment comprises melting crystallization equipment main body 9, and the inner wall of described melting crystallization equipment main body 9 is provided with ordinary interlayer 3 and refrigeration interlayer 4 , the common interlayer 3 is located inside the refrigeration interlayer 4, and the inner wall surface of the common interlayer 3 is coated with a non-stick coating that does not contain fluoride and combines metals; the top of the main body 9 of the melting and crystallization equipment is provided with a feed port 1, A discharge port 2 is provided at the bottom; a cold and hot medium inlet 31, a cold and hot medium outlet 32, a refrigerant inlet 41 and a refrigerant outlet 42 are also provided on the side wall of the main body 9 of the melting and crystallization equipment;

[0051] The inside of the main bod...

Embodiment 3

[0057] A method for melting co-crystallization of erythritol and high-intensity sweeteners, comprising steps as follows:

[0058] (1) Put the erythritol crystals into the crystallization equipment and heat up to 150°C; after the erythritol crystals are completely dissolved, cool down to 118°C and keep warm for 30min to prepare the erythritol solution;

[0059] (2) Make a suspension with high-intensity sweetener and water at a mass ratio of 1:2, then stir at 90-95°C until dissolved, then slowly add 0.8% of the mass of erythritol to the crystallization equipment , making erythritol-high-intensity sweetener mixed solution;

[0060] (3) Stir the erythritol-high-intensity sweetener mixture prepared in step (2) at a rate of 28°C and 250r / min for 25min, and then cool the melting and crystallization equipment to 105°C at a rate of 0.5°C / min. °C, and then rapidly cooled to 70 °C at a rate of 5 °C per minute to prepare erythritol-high-intensity sweetener co-crystals.

[0061] The high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com