Process for deodorizing sewage plant by using magnetic nanofiber

A magnetic nanotechnology, sewage treatment plant technology, applied in the direction of gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of difficult collection, high investment cost, high power consumption, etc., to achieve the effect of ensuring the growth state and improving the removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

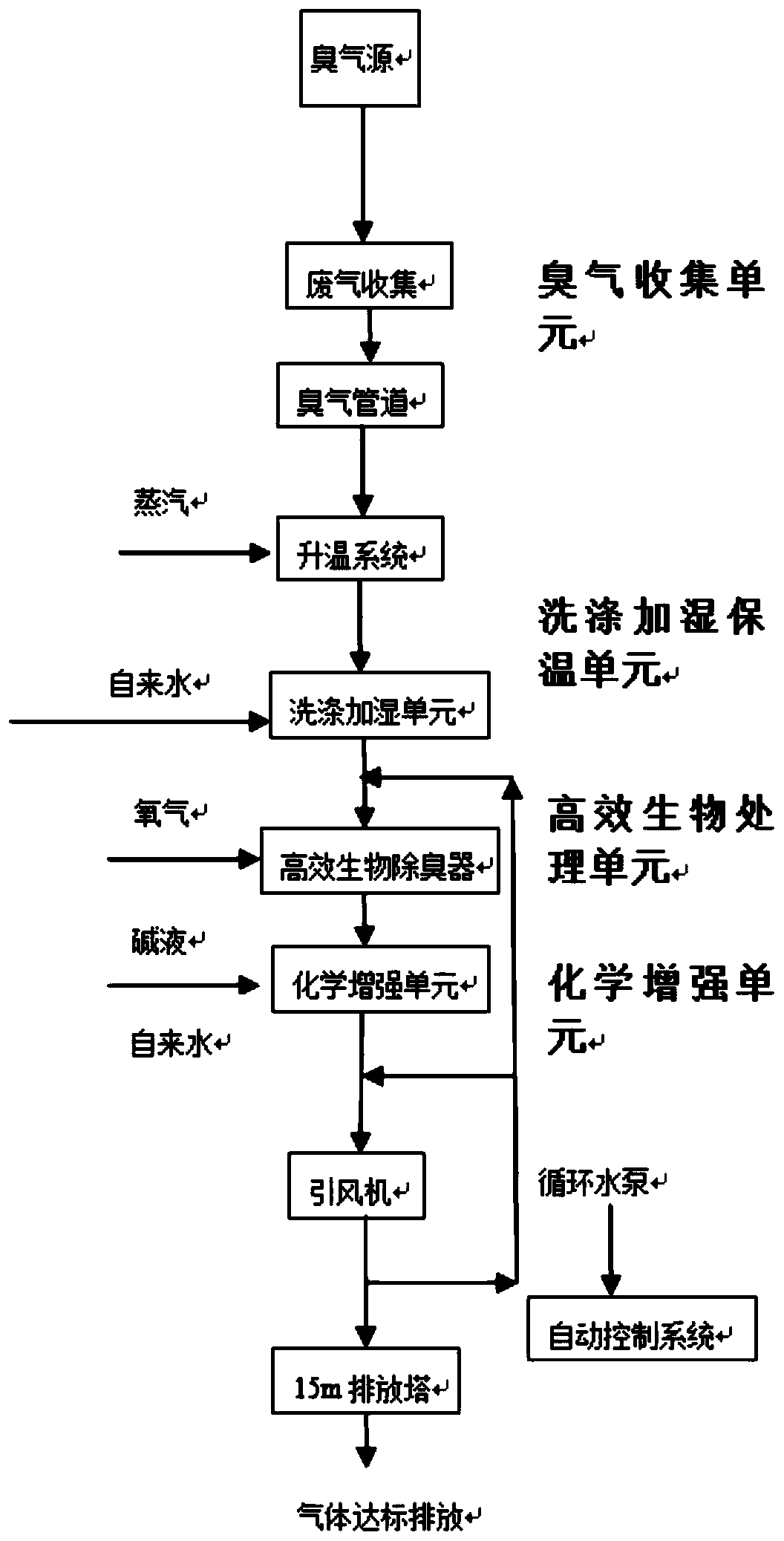

[0031] A process for deodorizing magnetic nanofibers in sewage plants, including an odor collection unit, a humidification and heat preservation unit, a washing, humidification and heat preservation unit, a high-efficiency biological treatment unit, a chemical enhancement unit, and a discharge unit. These five units are composed of five units. The treatment method Specifically include the following steps:

[0032] S1. Odor collection unit: collect the odor in the sewage plant through the ventilation equipment, and pass the collected odor into the washing and humidification unit for treatment. The ventilation equipment is an exhaust fan;

[0033] S2. Washing, humidification and heat preservation unit: the odor collected in step S1 is sprayed to remove the water-soluble components in the odor, and the odor is humidified, and then the odor after spraying and washing is heated by a heating device. Heating and heat preservation to ensure the best growth state of microorganisms and ...

Embodiment 2

[0038] A process for deodorizing magnetic nanofibers in sewage plants, including an odor collection unit, a humidification and heat preservation unit, a washing, humidification and heat preservation unit, a high-efficiency biological treatment unit, a chemical enhancement unit, and a discharge unit. These five units are composed of five units. The treatment method Specifically include the following steps:

[0039] S1. Odor collection unit: collect the odor in the sewage plant through ventilation equipment, and pass the collected odor into the washing and humidification unit for treatment. The ventilation equipment adopts C6-48 centrifugal fan;

[0040] S2. Washing, humidification and heat preservation unit: the odor collected in step S1 is sprayed to remove the water-soluble components in the odor, and the odor is humidified, and then the odor after spraying and washing is heated by a heating device. Heating and heat preservation to ensure the best growth state of microorganis...

Embodiment 3

[0045] A process for deodorizing magnetic nanofibers in sewage plants, including an odor collection unit, a humidification and heat preservation unit, a washing, humidification and heat preservation unit, a high-efficiency biological treatment unit, a chemical enhancement unit, and a discharge unit. These five units are composed of five units. The treatment method Specifically include the following steps:

[0046] S1. Odor collection unit: collect the odor in the sewage plant through the ventilation equipment, and pass the collected odor into the washing and humidification unit for treatment. The ventilation equipment is a cyclone dust collector;

[0047] S2. Washing, humidification and heat preservation unit: the odor collected in step S1 is sprayed to remove the water-soluble components in the odor, and the odor is humidified, and then the odor after spraying and washing is heated by a heating device. Heating and heat preservation to ensure the best growth state of microorga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com