A kind of nanofiltration composite membrane, preparation method and application

A composite membrane and nanofiltration technology, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of secondary pollution and high water pH requirements, achieve high negative charge performance, efficient removal rate, and improve size screening performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of the nanofiltration membrane that is used for heavy metal complex ion removal in the present embodiment comprises the following steps:

[0040] 1) Using water as a solvent, prepare a graphene oxide (GO) dispersion with a concentration of 10 mg / mL;

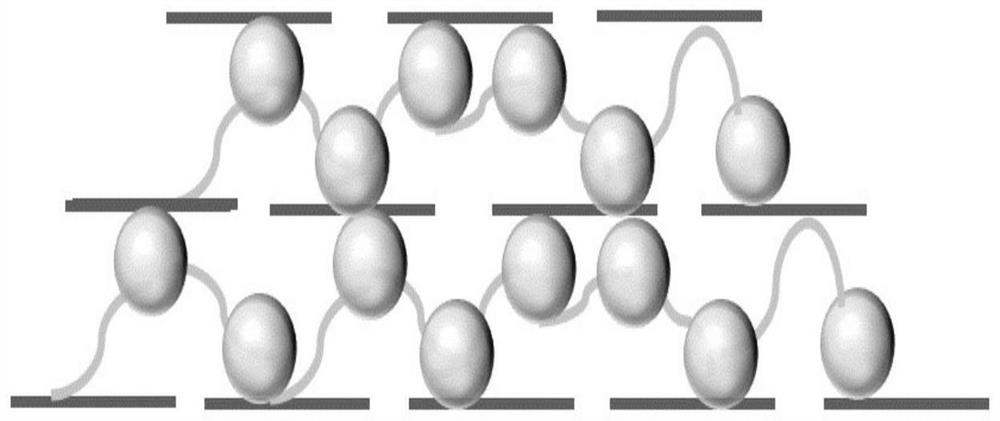

[0041]2) Dissolve polymethacrylic acid (PMAA) in dimethylacetamide (DMAc) to obtain a solution (PMAA / DMAc) with a concentration of 100 mg / ml, and continuously add petroleum ether under stirring conditions to induce the formation of polymer gel Colloidal particles, further causing the polymer to undergo a nucleophilic reaction to obtain a dispersion containing negatively charged polymer gel particles; the added volume of petroleum ether accounts for 5% of the total volume of the solution; the particle size of the polymer gel particles is confirmed by TEM characterization 0.5-10nm.

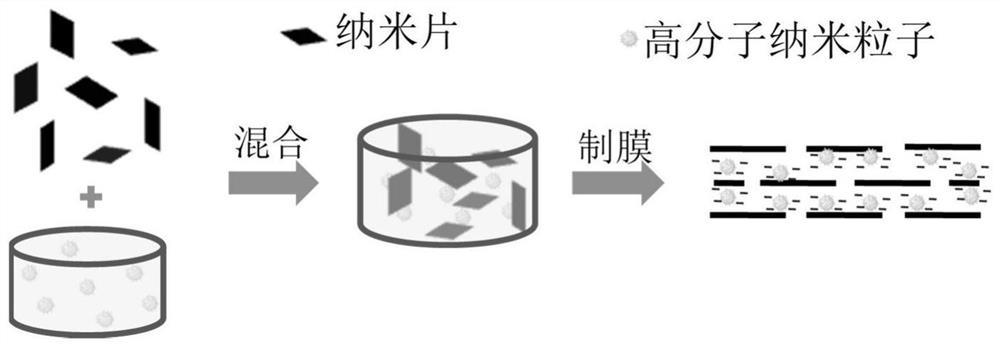

[0042] 3) the graphene oxide (GO) dispersion in step 1) is blended with the solution obtained in step 2), and the mass ...

Embodiment 2

[0047] The preparation method of the nanofiltration composite membrane used for the removal of heavy metal complex ions in the present embodiment comprises the following steps:

[0048] 1) Using water as a solvent, prepare molybdenum disulfide (MoS2) with a concentration of 0.02 mg / mL 2 )Dispersions;

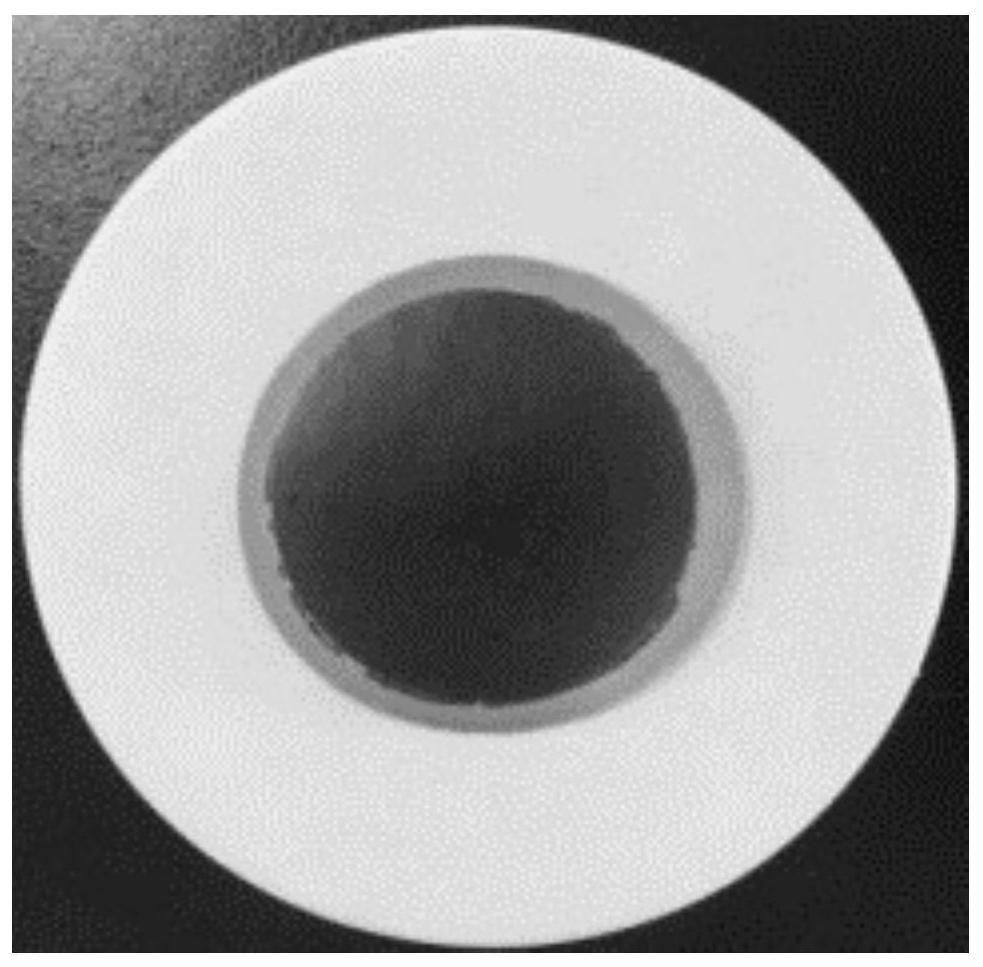

[0049] 2) Dissolve polyacrylonitrile (PAN) in N-methylpyrrolidone (NMP) to obtain a solution (PAN / NMP) with a concentration of 1mg / ml, and add water continuously under stirring conditions, and the volume of water added accounts for the total volume of the solution 15% of the polymer material is subjected to nucleophilic reaction to obtain a dispersion of negatively charged polymer gel particles; the particle size of the polymer gel particles is confirmed to be 0.5-10 nm by TEM characterization;

[0050] 3) Molybdenum disulfide (MoS2) in step 1) 2 ) dispersion and the solution obtained in step 2) are blended, the mass ratio between molybdenum disulfide and polyacrylonitrile in ...

Embodiment 3

[0052] The preparation method of the nanofiltration composite membrane used for the removal of heavy metal complex ions in the present embodiment comprises the following steps:

[0053] 1) Using water as a solvent, prepare a GO dispersion with a concentration of 0.001 mg / mL;

[0054] 2) Prepare polymethyl acrylate solution (PMA / NMP, 0.1 mg / ml), add absolute ethanol continuously under the condition of stirring, and the volume of ethanol added accounts for 85% of the total volume of the solution, so that the polymer material is subjected to nucleophilic reaction to obtain band A dispersion of negatively charged polymer gel particles; the particle size of the polymer gel particles is confirmed to be 0.5-10 nm by TEM characterization.

[0055] 3) Blend the GO dispersion in step 1) with the solution obtained in step 2), the mass ratio between GO and PMA in the blended solution is 1:10, and use a homogenizer to make a film , the film thickness is controlled at 5nm; after it is drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com