Universal preparation method and application of hierarchical-pore nitrogen-doped carbon catalyst synthesized on basis of double pore-foaming agents

A nitrogen-doped carbon, hierarchical pore technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of multi-price defect sites, uneven distribution, and poor order of carbon materials. and other problems, to achieve the effect of environmental friendliness, increase specific surface area, and increase pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

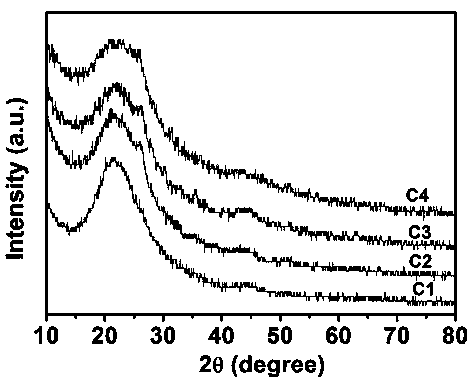

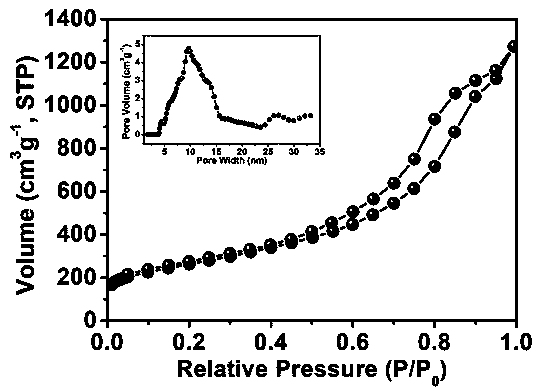

Embodiment 1

[0028] (1) Fully mix 1g of biomass chitosan with water and dry to obtain material A1;

[0029] (2) Transfer material A1 to a nickel boat and place it in a tube furnace. Under the protection of nitrogen gas with a flow rate of 100mL / min, the temperature is raised from room temperature to 300°C for 60 minutes, and then heated at a rate of 10°C / min. Raise the temperature to 800°C for 120 minutes, then cool down to room temperature naturally to obtain material B1;

[0030] (3) Transfer material B1 to a 100mL beaker, add acidic solution to soak for 12 hours, then wash with high-purity water until the filtrate is neutral, and then dry in a blast drying oven at 40°C for 12 hours to obtain carbon catalyst C1;

[0031] (4) The prepared carbon catalyst C1 was used as the cathode material of the electro-Fenton system to degrade 50mL malachite green solution with a concentration of 15mg / L, and the complete degradation time was 120min.

Embodiment 2

[0033] (1) Mix 1g of biomass chitosan and 2.5g of EDTA-2Na-Co with water, stir with a magnetic stirrer for 2 hours, mix well and dry to obtain material A2;

[0034] (2) Transfer the material A2 to a porcelain boat and place it in a tube furnace. Under the protection of nitrogen gas with a flow rate of 100mL / min, raise the temperature from room temperature to 300°C for 60 minutes, and then increase the temperature at a rate of 10°C / min. Raise the temperature to 800°C for 120 minutes, then cool down to room temperature naturally to obtain material B2;

[0035] (3) Transfer material B2 to a 100mL beaker, add acidic solution to soak for 12 hours, then wash with high-purity water until the filtrate is neutral, and then dry at 40°C for 12 hours in a blast drying oven to obtain carbon catalyst C2;

[0036] (4) The prepared carbon catalyst C2 was used as the cathode material of the electro-Fenton system to degrade 50mL malachite green solution with a concentration of 15mg / L, and the c...

Embodiment 3

[0038] (1) Mix 1g of biomass chitosan and 2.5g of molecular sieve SBA-15 with water, stir with a magnetic stirrer for 2 hours, mix well and dry to obtain material A3;

[0039] (2) Transfer material A3 to a nickel boat and place it in a tube furnace. Under the protection of nitrogen gas with a flow rate of 100mL / min, the temperature is raised from room temperature to 300°C for 60 minutes, and then heated at a rate of 10°C / min. Raise the temperature to 800°C for 120 minutes, then cool down to room temperature naturally to obtain material B3;

[0040] (3) Transfer material B3 to a 100mL beaker, add acidic solution to soak for 12 hours, then wash with high-purity water until the filtrate is neutral, and then dry at 40°C for 12 hours in a blast drying oven to obtain carbon catalyst C3;

[0041] (4) The prepared carbon catalyst C3 was used as the cathode material of the electro-Fenton system to degrade 50mL malachite green solution with a concentration of 15mg / L, and the complete de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com