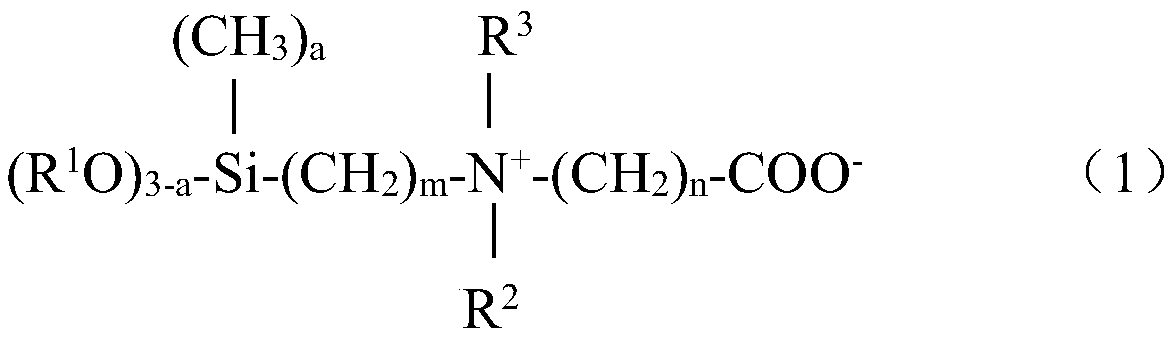

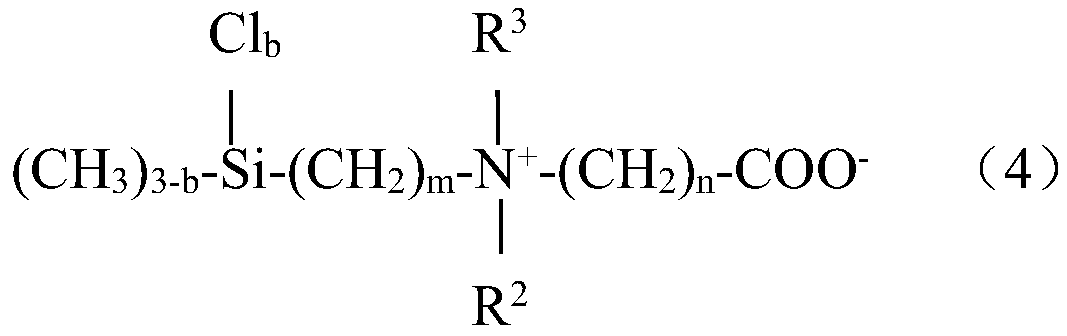

Zwitterionic ammonium carboxylate type silane coupling agent, siloxane ring body and preparation method of zwitterionic ammonium carboxylate type silane coupling agent and siloxane ring body

A silane coupling agent, siloxane ring technology, applied in the field of new zwitterionic compounds, can solve the problems of limited types and lack of commercial products, and achieve the effect of efficient synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

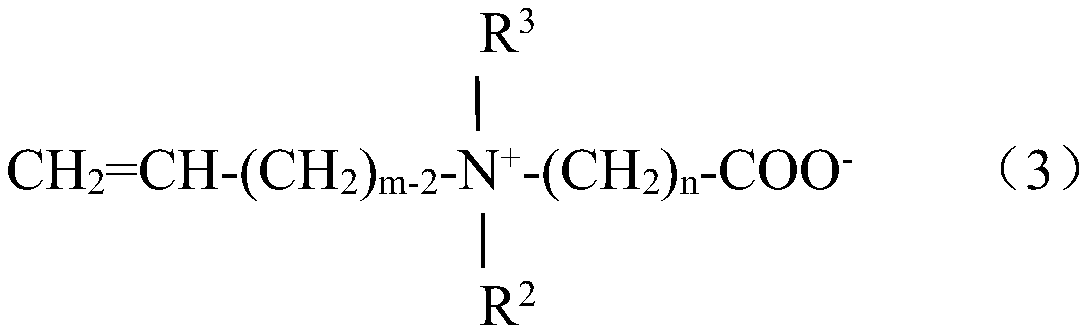

Embodiment 1

[0044] Preparation of the first intermediate: add 100 grams of allyldimethylamine, 120 grams of sodium chloroacetate and 400 grams of absolute ethanol to a 1-liter three-necked round-bottomed flask, heat to 80° C. under nitrogen protection and reflux and stir for 12 hours. The ammonization reaction yields a mixture containing allyldimethylammonium acetate zwitterion internal salt (first intermediate), a small amount of unreacted allyldimethylamine and sodium chloride. The mixture is concentrated under reduced pressure or vacuum distilled to obtain the allyl dimethyl ammonium acetate zwitterion inner salt-sodium chloride crystallization mother liquor, the crystallization mother liquor is initially evaporated and concentrated, and a small amount of isopropanol is added to obtain the crude mixed crystal of sodium chloride, Wash with separation solvent to remove impurities, and combine the filtrates. The separation solvent is a mixed solvent of absolute ethanol and methanol, where...

Embodiment 2

[0054] Preparation of the first intermediate: Add 100 grams of allyldimethylamine, 93.2 grams of sodium chloroacetate and 400 grams of absolute ethanol to a 1-liter three-necked round-bottomed flask, heat to 90° C. under nitrogen protection and reflux and stir for 10 hours. The ammonization reaction yields a mixture containing allyldimethylammonium acetate zwitterion internal salt (first intermediate), a small amount of unreacted allyldimethylamine and sodium chloride. The mixture is concentrated under reduced pressure or vacuum distilled to obtain the allyl dimethyl ammonium acetate zwitterion inner salt-sodium chloride crystallization mother liquor, the crystallization mother liquor is initially evaporated and concentrated, and a small amount of isopropanol is added to obtain the crude mixed crystal of sodium chloride, Wash with separation solvent to remove impurities, and combine the filtrates. The separation solvent is a mixed solvent of absolute ethanol and methanol, wher...

Embodiment 3

[0064] Preparation of the first intermediate: add 100 grams of allyldimethylamine, 108.4 grams of sodium chloroacetate and 400 grams of absolute ethanol to a 1-liter three-necked round-bottomed flask, heat to 70° C. under nitrogen protection and reflux and stir for 14 hours. The ammonization reaction yields a mixture containing allyldimethylammonium acetate zwitterion internal salt (first intermediate), a small amount of unreacted allyldimethylamine and sodium chloride. The mixture is concentrated under reduced pressure or vacuum distilled to obtain the allyl dimethyl ammonium acetate zwitterion inner salt-sodium chloride crystallization mother liquor, the crystallization mother liquor is initially evaporated and concentrated, and a small amount of isopropanol is added to obtain the crude mixed crystal of sodium chloride, The solvent was separated and washed to remove impurities, and the filtrates were combined. The separation solvent is a mixed solvent of absolute ethanol and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com