Adhesive composition adhesive and adhesive sheet

A composition and adhesive technology, applied in the direction of adhesive type, cyclodextrin adhesive, ester copolymer adhesive, etc., can solve the problem of light reflection loss, etc., and achieve the effect of reducing the haze value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0091] (2) Preparation of adhesive composition

[0092] The adhesive composition P can be prepared by preparing the (meth)acrylate polymer (A), mixing the obtained (meth)acrylate polymer (A) with the polyrotaxane compound (B), and simultaneously A crosslinking agent (C), an active energy ray-curable component (D), additives, and the like are added as necessary.

[0093] The (meth)acrylate polymer (A) can be produced by polymerizing a mixture of monomers constituting a polymer by a normal radical polymerization method. It is preferable to perform polymerization of a (meth)acrylate polymer (A) by the solution polymerization method using a polymerization initiator as needed. However, the present invention is not limited thereto, and polymerization may be performed without a solvent. Examples of the polymerization solvent include ethyl acetate, n-butyl acetate, isobutyl acetate, toluene, acetone, hexane, methyl ethyl ketone, and the like, and two or more of them may be used in c...

Embodiment 1

[0157] 1. Preparation of (meth)acrylate polymer

[0158] A (meth)acrylate polymer was prepared by copolymerizing 80 parts by mass of 2-ethylhexyl acrylate, 5 parts by mass of 2-phenoxyethyl acrylate, and 15 parts by mass of 2-hydroxyethyl acrylate by a solution polymerization method. As a result of measuring the molecular weight of this (meth)acrylate polymer (A) by the method mentioned later, the weight average molecular weight (Mw) was 600,000.

[0159] 2. Preparation of Adhesive Composition

[0160] 100 parts by mass of the (meth)acrylate polymer (A) obtained in the above step 1 (solid content conversion value; the same applies hereinafter), a polyrotaxane compound (B) (manufactured by Advanced Softmaterials Inc., product name "SeRM SuperPolymer SH3400P", linear molecule: polyethylene glycol, cyclic molecule: α-cyclodextrin with hydroxypropyl and caprolactone chains, capping group: adamantyl, weight average molecular weight (Mw) 700,000 , hydroxyl value 72 mgKOH / g) 5.0 pa...

Embodiment 2~8

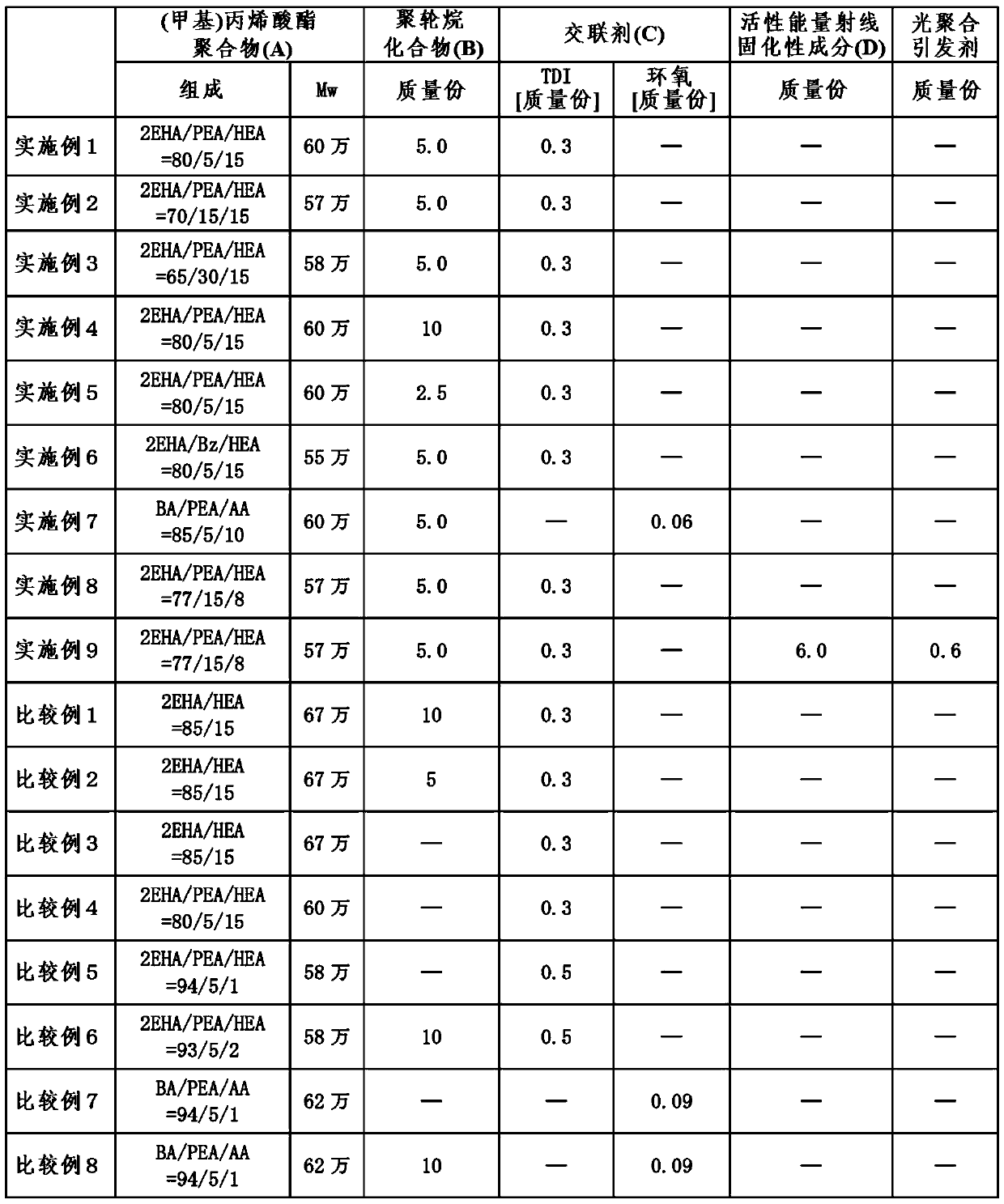

[0176] [Examples 2-8, Comparative Examples 1-8]

[0177] In addition to the type and ratio of each monomer constituting the (meth)acrylate polymer (A), the weight average molecular weight of the (meth)acrylate polymer (A), and the blending amount of the polyrotaxane compound (B) , and the type and compounding amount of the crosslinking agent (C) were changed to those shown in Table 1, and an adhesive sheet was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com