Anti-dazzle hardened film for liquid crystal display

A technology of liquid crystal display and hardened film, applied in optics, optical components, coatings, etc., can solve the problems of transparent film surface but insufficient anti-glare effect, poor surface resin adhesion, difficult to meet image display and other problems, and achieve excellent light transmission. rate, improve the appearance of the coating, improve the clarity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062]

[0063] 15 parts by weight of the polyurethane acrylate (Changxing Company 6115J-80) was added to 68.85 parts by weight of solvent (13.7 parts by weight of methyl isobutcloths, 41.31 parts by weight of ethyl acetate and 13.7 parts by weight of isopropanol), dissolved and stirred . Continue to add 0.15 parts by weight of the polyether silicone flow plane (Shaki Company BYK-3710), 5 parts by weight of tertiary amine acrylate (cyanide 7100), and 3 parts by weight of photoinitiator 1-hydroxyl ring Phenyl ketone, stir well. Finally, 3 parts by weight of micron organic particles (Yongqi Material Co., Ltd. HL602, particle diameter 3 μm) and 5 parts by weight of nano-modified silica particles (Deguri A200, particle size 10 nm, SiO 2 -1) Perform 20 min high-speed agitation dispersion, and the stirring speed was 1200 r / min.

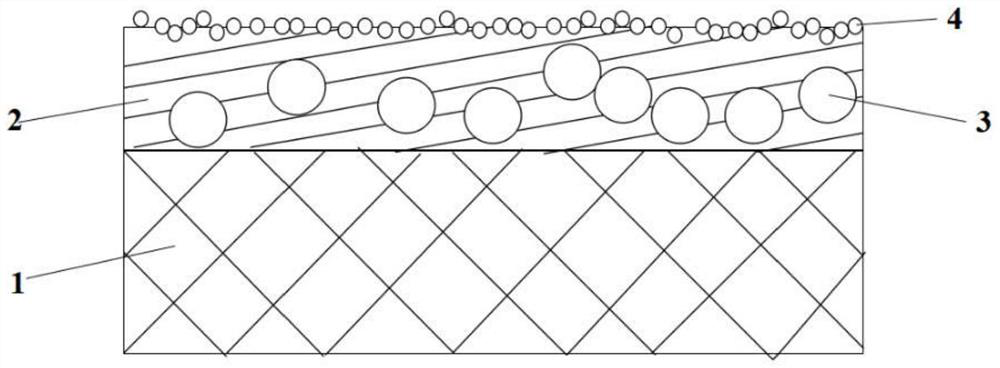

[0064] The coating liquid was applied to the side of the optical grade polyethylene cellulose thin film (TAC film) having a thickness of 80 μm, and dried i...

Embodiment 2

[0066]

[0067] 25 parts by weight of polyurethane acrylate (Changxing Company 6115J-80) was added to 68.85 parts by weight of solvent (13.7 parts by weight of methyl isobutcloths, 41.31 parts by weight of ethyl acetate and 13.7 parts by weight of isopropanol), dissolved and stirred . Continue to add 0.15 parts by weight of polyether silicone flow plane (Byk-3710), 5 parts by weight of tertiary amine acrylate (cyanide 7100), and 3 parts by weight of photoinitiator 1-hydroxyl ring Phenyl ketone, stir well. Finally, 3 parts by weight of micron organic particles (Yongqi Material Co., Ltd. HL602, particle diameter 3 μm) and 5 parts by weight of nano-modified silica particles (Deguri A200, particle size 10 nm, SiO 2 -2) Perform 20 min high-speed stirring dispersion, stirring speed of 1200 r / min.

[0068] The coating liquid was applied to the side of the optical grade polyethylene cellulose thin film (TAC film) having a thickness of 80 μm, and dried in an oven at 60 ° C for 3 minute...

Embodiment 3

[0070]

[0071] 25 parts by weight of polyurethane acrylate (Changxing Company 6115J-80) was added to 68.85 parts by weight of solvent (13.7 parts by weight of methyl isobutcloths, 41.31 parts by weight of ethyl acetate and 13.7 parts by weight of isopropanol), dissolved and stirred . Continue to add 0.15 parts by weight of polyether silicone flow plane (Byk-3710), 5 parts by weight of tertiary amine acrylate (cyanide 7100), and 3 parts by weight of photoinitiator 1-hydroxyl ring Phenyl ketone, stir well. Finally, 3 parts by weight of micron organic particles (Yongqi Material Co., Ltd. HL602, particle diameter 3 μm) and 5 parts by weight of nano-modified silica particles (Deguri A200, particle size 10 nm, SiO 2 -3) Perform 20 min high-speed agitation dispersion, and the stirring speed was 1200 r / min.

[0072] The coating liquid was applied to the side of the optical grade polyethylene cellulose thin film (TAC film) having a thickness of 80 μm, and dried in an oven at 60 ° C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com