Silica gel composite membrane for collecting biological texture image, preparation method and purpose thereof

A texture image, composite film technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of unreported quality of fingerprint image collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Prepared according to the composition formula described in Table 1, stirred with a stirrer at 2000 rpm for 15 minutes, and stood for 10 minutes to defoam to obtain the desired room temperature vulcanized silicone rubber composition.

[0056] Table 1 Composition Formulation

[0057] components

Dosage / g

Vinyl terminated polydimethylsiloxane

100

10

3

Chloroplatinic acid catalyst

0.1

10

Leveling agent BYK-323

0.4

Defoamer BYK-066N

0.2

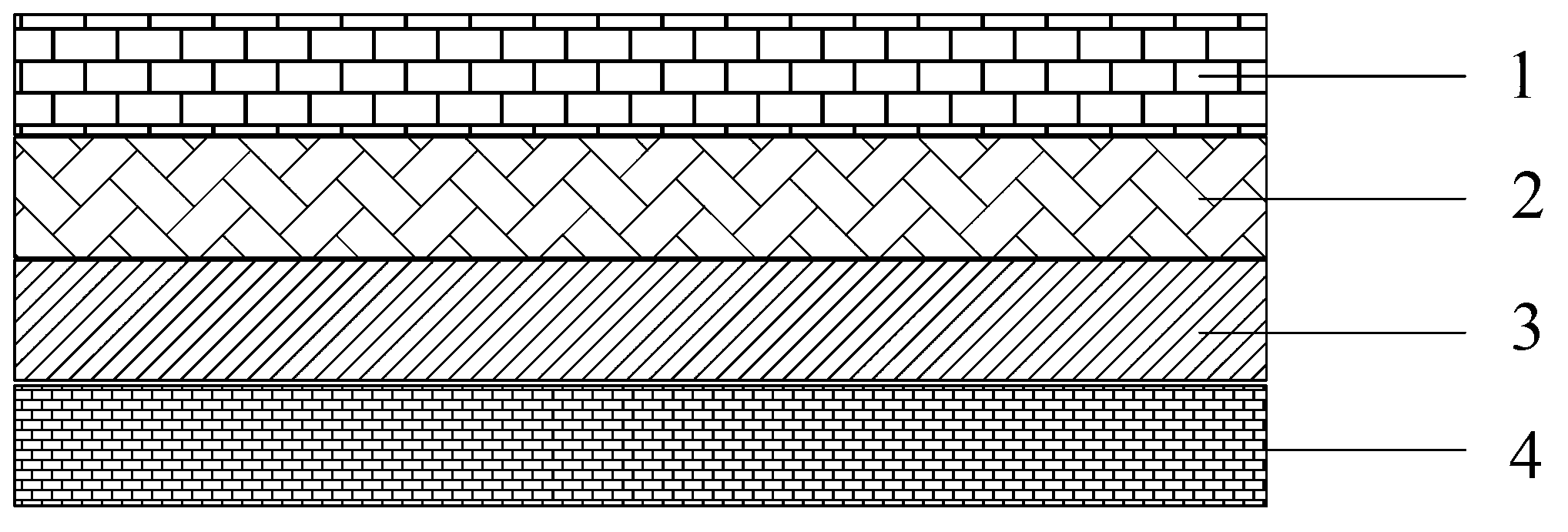

[0058]The polyethylene terephthalate film was corona-treated at a voltage of 15000V and an output power of 1000W, and then the above-mentioned room temperature vulcanized silicone rubber composition was uniformly coated on the corona-treated polyparaphenylene with a 100 μm wire bar. The surface of the ethylene glycol diformate substrate film 3; after coating, bake at 65° C. for 4 hours to fully cur...

Embodiment 2

[0061] Prepared according to the composition formula described in Table 2, stirred with a stirrer at 2000 rpm for 15 minutes, and stood for 10 minutes to defoam, to obtain the desired room temperature vulcanized silicone rubber composition.

[0062] Table 2 Composition Formulation

[0063] components

Dosage / g

Hydroxy-terminated polydimethylsiloxane

100

20

Methyltriethoxysilane

8

2

Leveling agent BYK-333

0.4

Defoamer BYK-A530

0.2

Non-ionic antistatic agent

0.3

[0064] Coat a layer of adhesion promoter on the surface of the polycarbonate film, let it dry for a period of time, then fix it on a spin coater, and uniformly coat the above room temperature vulcanized silicone rubber composition at a rotation speed of 2500 rpm coated on the polycarbonate substrate film 3 treated with primer, and cured at 23° C. for 24 hours after coating. Finally, ...

Embodiment 3

[0067] Prepared according to the composition formula described in Table 3, stirred with a stirrer at 2000 rpm for 15 minutes, and stood for 10 minutes to defoam, to obtain the desired room temperature vulcanized silicone rubber composition.

[0068] Table 3 Composition Formulation

[0069] components

Dosage / g

Vinyl-terminated polymethylphenylsiloxane

100

50

Methyltriacetoxysilane

6.6

0.7

50

Leveling agent BYK-350

0.67

Defoamer BYK-320

0.33

[0070] After the plasma treatment of the polymethyl methacrylate film, the above-mentioned room temperature vulcanized silicone rubber composition is uniformly coated on the surface of the plasma-treated polymethyl methacrylate substrate film 3 with a 100 μm wire bar; Bake at 65°C for 4 hours to fully cure the silica gel, and finally a composite film with a smooth surface, high light transmittance, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com