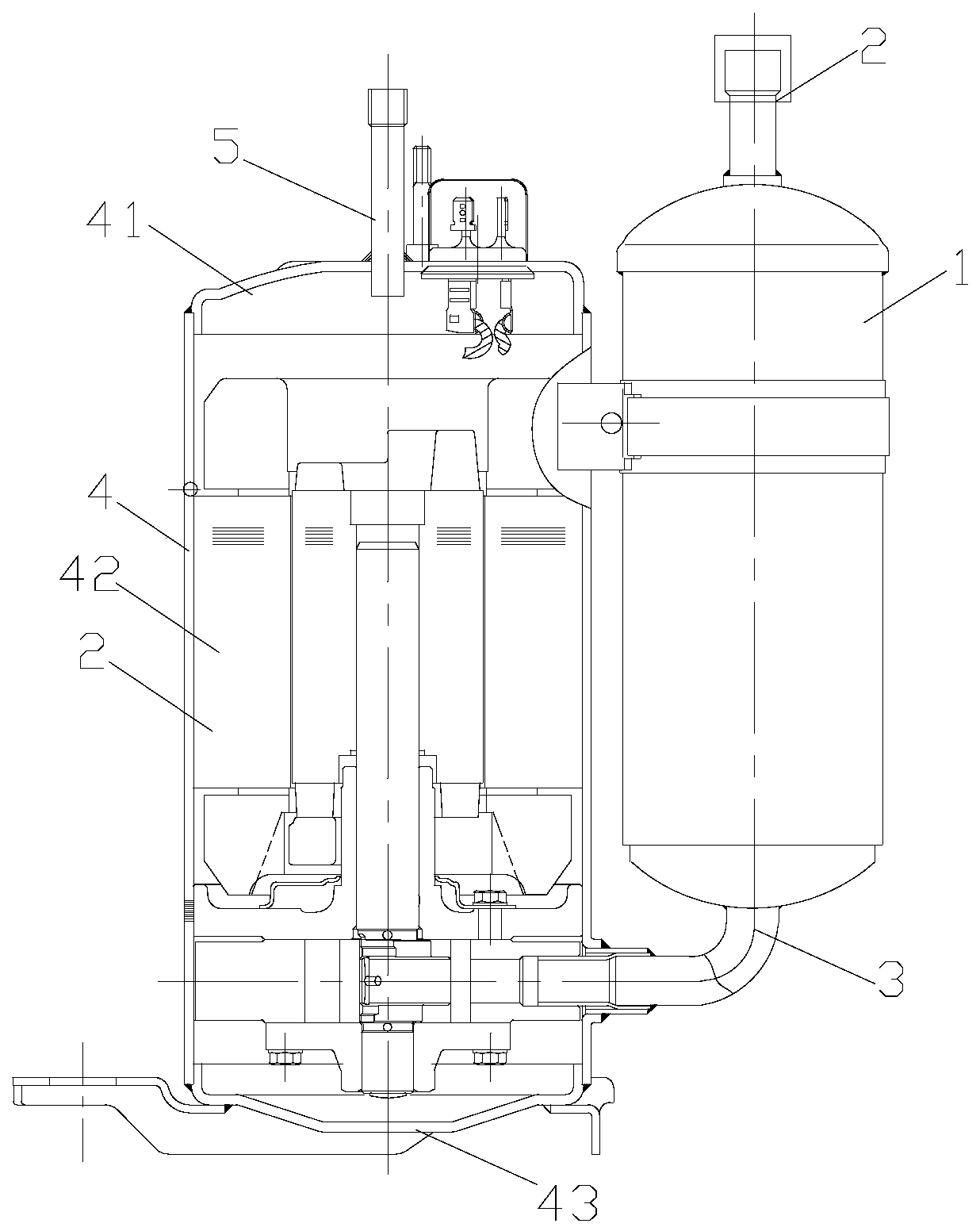

Connecting pipe structure

A technology for connecting pipes and nozzles, which is applied in the direction of pipes/pipe joints/fittings, pipes, branch pipelines, etc., which can solve the problems of copper pipe strength and fatigue resistance decline, inability to batch, high cost, etc., to shorten the preparation time, Energy saving and low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the above-mentioned connecting pipe structure 7: the welding of the copper lining pipe 73, the iron connecting base 72 and the pipe body 71 can be performed during, before or after the aforementioned surface treatment process. When the temperature range of the surface treatment process is within the welding temperature (800-1082° C.) range of the copper lining pipe 73 , the welding can be completed synchronously during the surface treatment process. The copper lining pipe 73 is welded for subsequent welding with copper pipes or composite pipes with copper welding parts. Since phosphorus copper solder is generally used for subsequent welding with copper air-conditioning piping, and the welding temperature is above 720°C, it is preferable to use solder with a solder temperature of not lower than 800°C (such as tin bronze solder) for welding the copper lining pipe 73 and the pipe body 71 . Preferably, the welding condition of the copper-lined pipe...

Embodiment 1

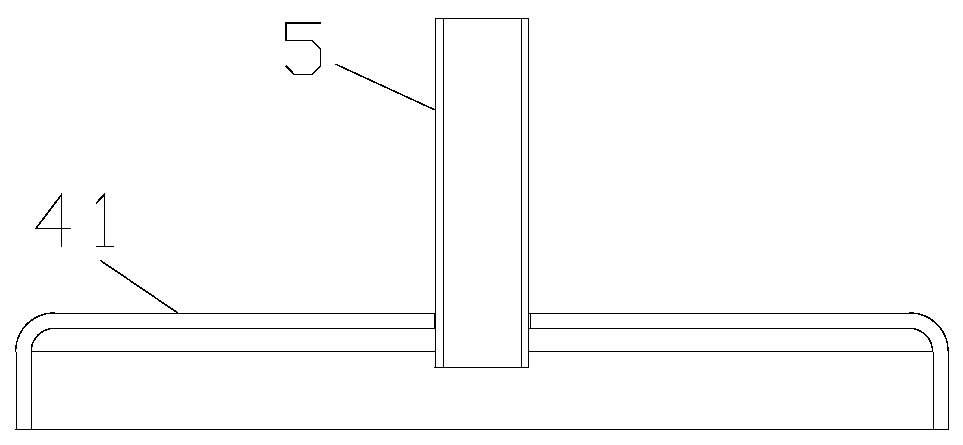

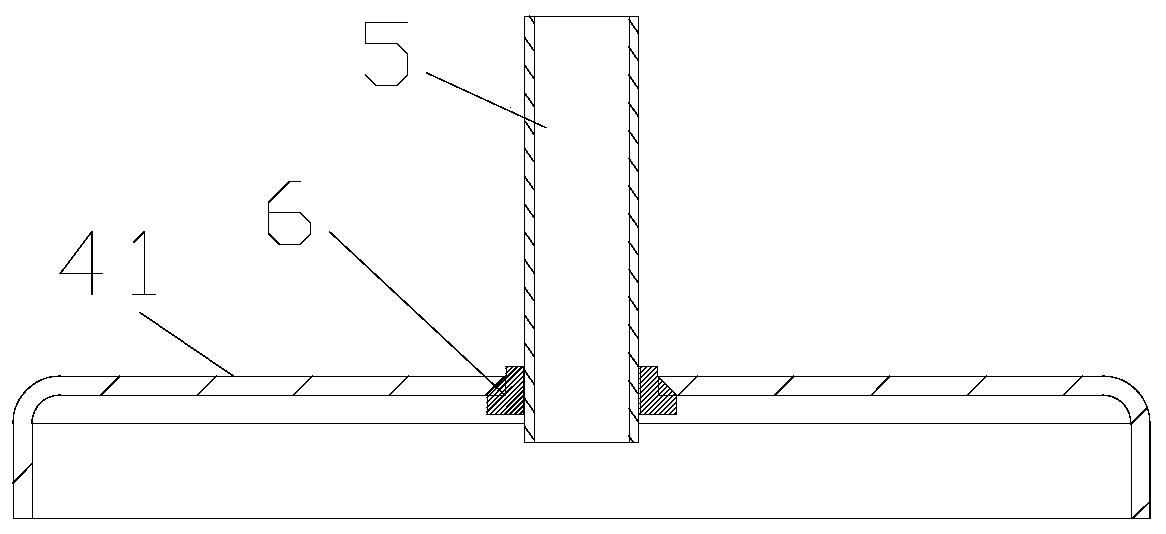

[0038] Embodiment 1 (chromizing)

[0039] like Figure 4 As shown, in this embodiment, the connecting pipe structure 7 includes a pipe body 71. The pipe body 71 is a straight iron-based pipe, and a copper lining pipe 73 is welded in the mouth of one end of the pipe. The outer surface of the port starts from the edge of the port. The area (about 10 mm) extending to the other end with a distance D of not less than 5 mm has a corrosion-resistant layer 74; the other end is externally fixed with an iron connection base 72 for resistance welding connection with the shell.

[0040] One end of the pipe body 71 forms an anti-corrosion layer 74 (such as Figure 5 shown), then the copper lining pipe 73, the iron connection base 72 and the pipe body 71 are assembled as a whole and filled with solder, and sent to a high temperature furnace for welding. The welding condition is that the temperature is 800-1082 °C (this temperature is the furnace The actual temperature of the inner product...

Embodiment 2

[0044] Embodiment 2 (copper and iron diffusion)

[0045] like Image 6 As shown, in this embodiment, an anti-corrosion layer 74 is formed at one end of the pipe body 71 through a copper-iron diffusion process. The copper-iron diffusion process is to first plate copper to form a copper coating, and then heat at a high temperature to make the surfaces of copper and iron pipes diffuse mutually. Therefore, in this embodiment, the copper lining pipe 73 and the iron connection base 72 can be connected to each other after copper plating. Assemble with the tube body 71 and fill it with solder, then enter the high-temperature furnace to make the copper and iron interdiffused and weld the three at the same time, the condition is that the temperature is 800-1082°C (this temperature is the actual temperature of the product surface in the furnace) in a high-temperature furnace Overheat for 3 minutes or more. like Figure 7 As shown, the anti-corrosion layer 74 is a layer of copper-iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com