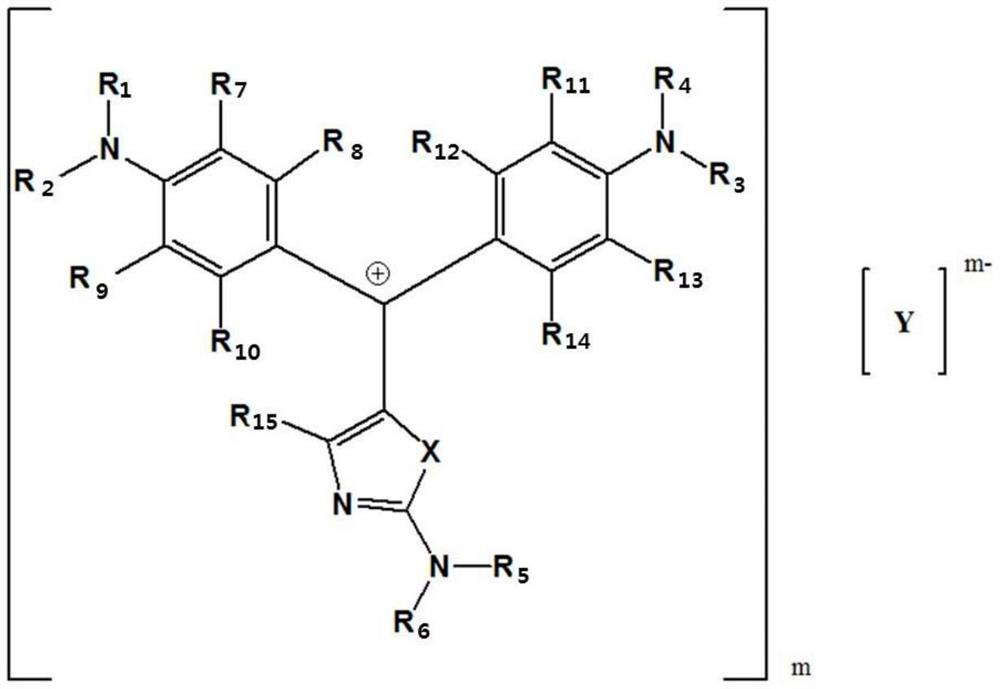

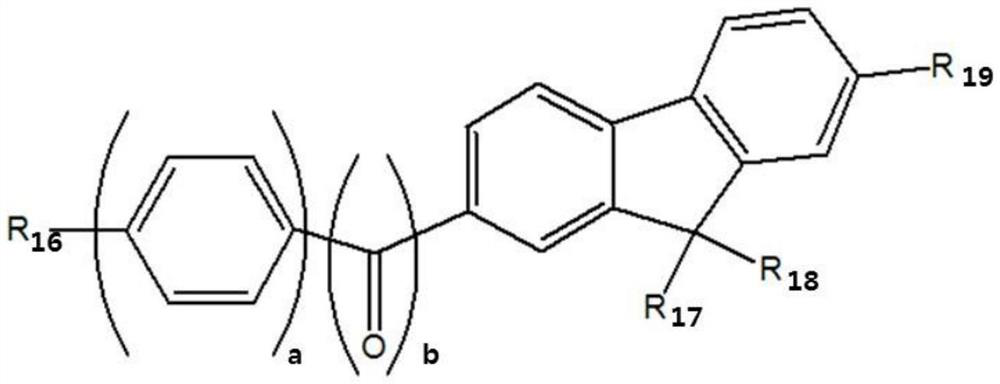

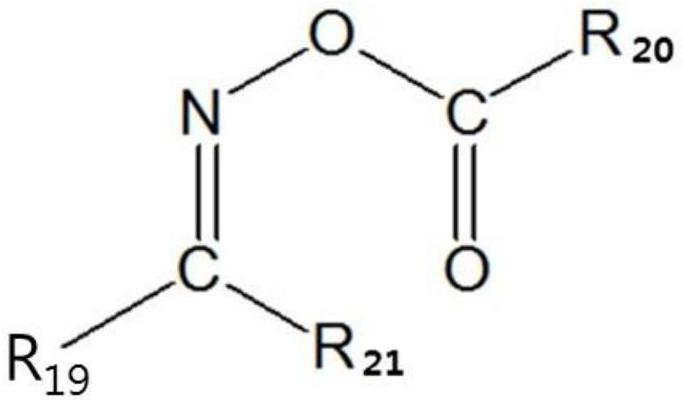

Cyan photosensitive resin composition, cyan color filter and display device comprising same

A photosensitive resin and composition technology, applied in the field of cyan color filters and display devices, can solve the problems of pattern peeling, contrast reduction, dye precipitation, etc., achieve high transmission and contrast, excellent adhesion, and excellent color reproduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0267] Synthesis example 1. Synthesis of alkali-soluble resin

[0268] Into a flask with a reflux condenser, a dropping funnel (dropping funnel) and a stirrer, flow an appropriate amount of nitrogen, replace it with a nitrogen atmosphere, charge 100 parts by weight of propylene glycol monomethyl ether acetate, and heat to 85°C while stirring .

[0269] Next, 19 parts by weight of methacrylic acid, 3,4-epoxytricyclo[5.2.1.02.6]decane-8- A mixture of 3,4-epoxytricyclo[5.2.1.02.6]decane-9-yl acrylate (50:50 molar ratio) (trade name "E-DCPA", manufactured by Daicel Corporation) ) 171 parts by weight dissolved in a solution of 40 parts by weight of propylene glycol monomethyl ether acetate.

[0270] Using another drip pump, 26 parts by weight of the polymerization initiator 2,2'-azobis(2,4-dimethylvaleronitrile) dissolved in propylene glycol monomethyl ether ethyl alcohol was dripped into the flask over about 5 hours. A solution of 120 parts by weight of acid ester. After drop...

Synthetic example 2

[0291] 2-1.

[0292] This reaction was carried out under nitrogen atmosphere.

[0293] After putting 36.3 parts by weight of potassium thiocyanate and 160 parts by weight of acetone into a flask equipped with a cooling tube and a stirring device, it was stirred at normal temperature for 30 minutes. Then, 50 parts by weight of benzoyl chloride (manufactured by Tokyo Chemical Industry Co., Ltd.) was dripped over 10 minutes.

[0294] After the dropwise addition, it was stirred at normal temperature for 2 hours, and after the reaction mixture was ice-cooled, 45.7 parts by weight of N-ethyl-o-toluidine (manufactured by Tokyo Chemical Industry Co., Ltd.) was added dropwise. After completion of the dropping, stirring was carried out at normal temperature for 30 minutes.

[0295] Next, after ice-cooling the reaction mixture, 34.2 parts by weight of a 30% sodium hydroxide aqueous solution was added dropwise, and stirred at normal temperature for 30 minutes. Then, 35.3 parts by weig...

Synthetic example 3

[0320] 3-1.

[0321] 2 parts by weight of sodium hydroxide (manufactured by Wako Pure Chemical Industries, Ltd.) was dissolved in 50 parts by weight of methanol. Then, 15.41 parts by weight of 2,6-dihydroxybenzoic acid (manufactured by Tokyo Chemical Industry Co., Ltd.) and 3.09 parts by weight of boric acid (manufactured by Wako Pure Chemical Industries, Ltd.) were added, and stirred at 65° C. for 8.5 hours.

[0322] After the above mixed solution was cooled to normal temperature, the precipitate was obtained by suction filtration and washed with 237 parts by weight of ion-exchanged water to obtain 10.9 parts by weight of a compound of the following chemical formula 11.

[0323] [chemical formula 11]

[0324]

[0325] 3-2.

[0326] This reaction was carried out under nitrogen atmosphere.

[0327] 10 parts by weight of the compound of chemical formula 9 synthesized in the above synthesis example 2-2, 5.3 parts by weight of the compound of chemical formula 11 synthesize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com