2-ethylanthraquinone closed-loop liquid acid precipitation process

A technology of ethylanthraquinone and acid analysis, which is applied in the field of acid analysis of 2-ethylanthraquinone closed-loop liquid, can solve the problems of difficult comprehensive treatment of acidic wastewater, etc., so as to improve the economic benefits of enterprises, save resources, and improve the overall Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of acid analysis process of 2-ethylanthraquinone ring-closing liquid, it is characterized in that, comprises the following steps:

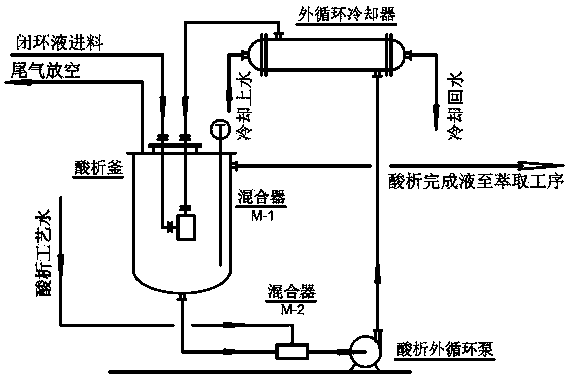

[0048] (1) Establish an acid analysis external circulation system: the acid analysis external circulation system is composed of an acid analysis kettle, an acid analysis external circulation pump, an external circulation cooler and two mixers in different positions; the closed-loop reaction completion liquid is introduced into the acid analysis The mixer (M-1) installed in the tank is fully mixed with the main fluid of the external circulation; while the static mixer (M-2) installed before the acid precipitation process water is introduced into the suction end of the external circulation pump, in addition to being effective with the main fluid In addition to mixing, it will be further mixed under the action of the impeller of the subsequent external circulation pump.

[0049] (2) In the acid precipitation external circulation system,...

Embodiment 2

[0057] like figure 1 Shown, a kind of acid out process of 2-ethylanthraquinone ring-closing liquid comprises the following steps:

[0058] (1) Establish an external circulation system for acid analysis: the external circulation system for acid analysis is composed of an acid analysis kettle, an external circulation pump for acid analysis, an external circulation cooler and two feed mixers in different positions, which greatly improves the completion of the closed-loop reaction The mixing efficiency and mass transfer and heat transfer effects of liquid and acid precipitation process water can effectively avoid the occurrence of corresponding side reactions.

[0059] The specific process is as follows: the closed-loop reaction completion liquid is introduced into the special mixer installed in the acid analysis tank, and fully mixed with the main fluid of the external circulation; and the acid analysis process water is introduced into the static mixer installed before the suctio...

Embodiment 3

[0067] like figure 1 shown, refer to figure 1 Build an experimental device with the function of simulating the external circulation.

[0068] Fill the laboratory external circulation device with a specified concentration of sulfuric acid aqueous solution in advance, start the special external circulation engineering plastic corrosion-resistant micro-metering pump, and establish a normal external circulation flow.

[0069] The closed-loop reaction liquid is introduced into the inlet of the special mixer set in the acid analysis tank, and mixed with the main fluid flowing into the mixer at high speed to carry out efficient mass transfer and heat transfer.

[0070] At the same time, fresh process water is introduced into the static mixer at the suction port of the circulating pump, mixed with the main fluid of the external circulation, and then enters the pump body of the circulating pump together, and is fully mixed again under the action of the shear force of the high-speed ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com