Anti-aging compactness essence ampoule stoste and preparation method thereof

An ampoule and essence technology, applied in the field of daily chemical industry, can solve the problems of skin relaxation, lack of elasticity, skin relaxation, aggravation, etc., to achieve the effect of supple and smooth skin, reduce wrinkles, and inhibit muscle contraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

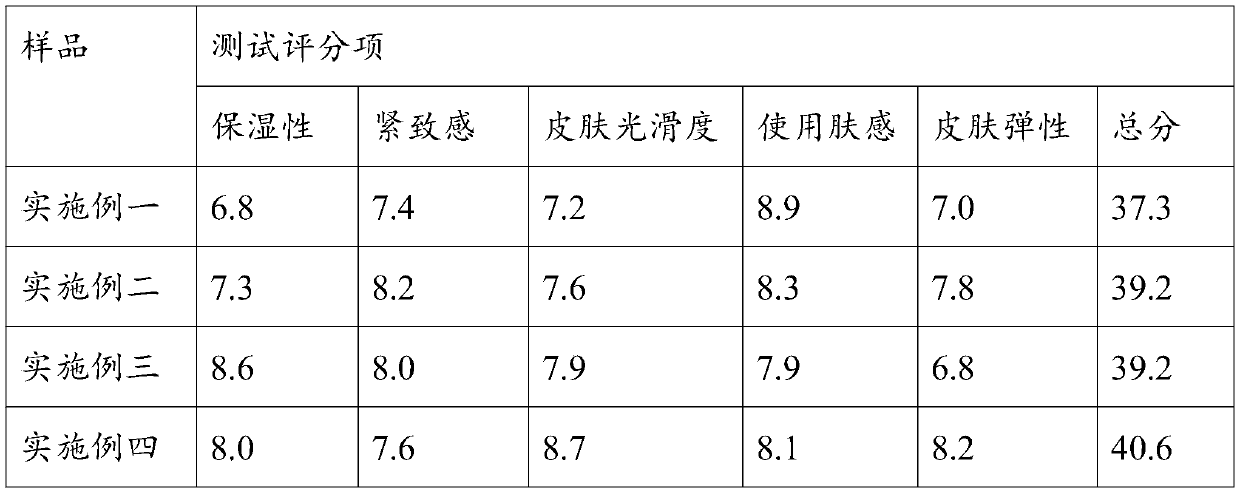

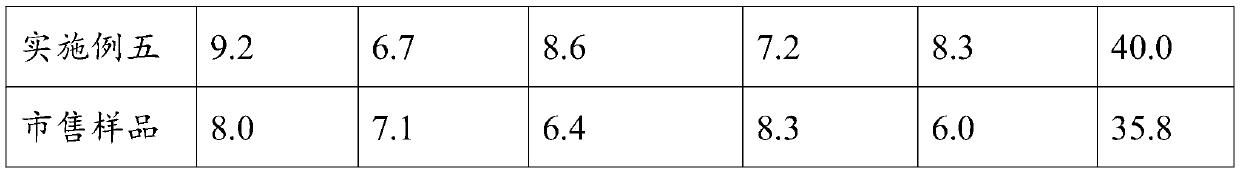

Examples

Embodiment 1

[0019] Based on 100 copies.

[0020] (1) Weigh 2 parts of acetylated sodium hyaluronate, 2 parts of sodium hyaluronate (2000-4000 Daltons), 0.1 part of sodium hyaluronate (1 million-1.4 million Daltons), Put 0.05 parts of sodium hyaluronate (2 million to 2.4 million Daltons), 3 parts of 1,2-pentanediol and 20 parts of water in a reaction kettle, stir and disperse evenly at a speed of 20-30 r / min, and heat Heat up to 80-85°C, cool down to 40-45°C in a sterile environment for standby;

[0021] (2) Weigh 10 parts of Bacillus fermentation product, 1 part of collagen, 3 parts of arginine / lysine polypeptide, 2 parts of dipeptide diaminobutyrylbenzylamide diacetate and the remainder by weight. Ionized water is placed in the reaction kettle of the step (1), stirred at a speed of 30-40r / min for 15-20min, stirred and dissolved evenly, and the transparent and clear material is obtained as the initial product;

[0022] (3) Submit the primary product prepared in the step (2) for inspecti...

Embodiment 2

[0024] Based on 100 copies.

[0025] (1) Weigh 2 parts of acetylated sodium hyaluronate, 2 parts of sodium hyaluronate (2000-4000 Daltons), 0.1 part of sodium hyaluronate (1 million-1.4 million Daltons), Put 0.05 parts of sodium hyaluronate (2 million to 2.4 million Daltons), 3 parts of 1,2-pentanediol and 20 parts of water in a reaction kettle, stir and disperse evenly at a speed of 20-30 r / min, and heat Heat up to 80-85°C, cool down to 40-45°C in a sterile environment for standby;

[0026] (2) Weigh 10 parts of Bacillus fermentation product, 3 parts of collagen, 8 parts of arginine / lysine polypeptide, 2 parts of dipeptide diaminobutyrylbenzylamide diacetate and the remainder by weight. Ionized water is placed in the reaction kettle of the step (1), stirred at a speed of 30-40r / min for 15-20min, stirred and dissolved evenly, and the transparent and clear material is obtained as the initial product;

[0027] (3) Submit the primary product prepared in the step (2) for inspect...

Embodiment 3

[0029] Based on 100 copies.

[0030] (1) Weigh 2 parts of acetylated sodium hyaluronate, 2 parts of sodium hyaluronate (2000-4000 Daltons), 0.1 part of sodium hyaluronate (1 million-1.4 million Daltons), Put 0.05 parts of sodium hyaluronate (2 million to 2.4 million Daltons), 3 parts of 1,2-pentanediol and 20 parts of water in a reaction kettle, stir and disperse evenly at a speed of 20-30 r / min, and heat Heat up to 80-85°C, cool down to 40-45°C in a sterile environment for standby;

[0031] (2) Weigh 10 parts of Bacillus fermentation product, 1 part of collagen, 3 parts of arginine / lysine polypeptide, 6 parts of dipeptide diaminobutyrylbenzylamide diacetate and the remainder by weight. Ionized water is placed in the reaction kettle of the step (1), stirred at a speed of 30-40r / min for 15-20min, stirred and dissolved evenly, and the transparent and clear material is obtained as the initial product;

[0032] (3) Submit the primary product prepared in the step (2) for inspecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com