Preparation method of cement grinding aid

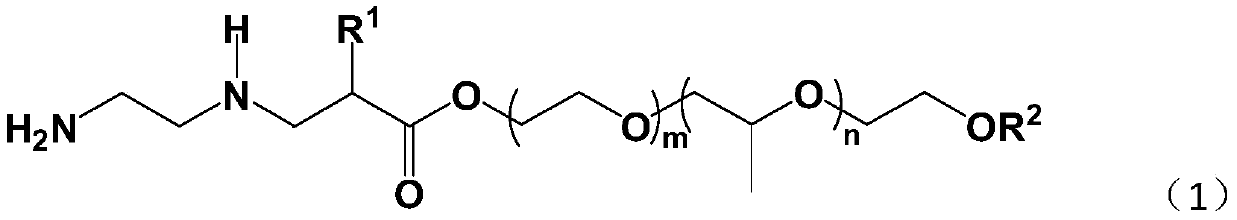

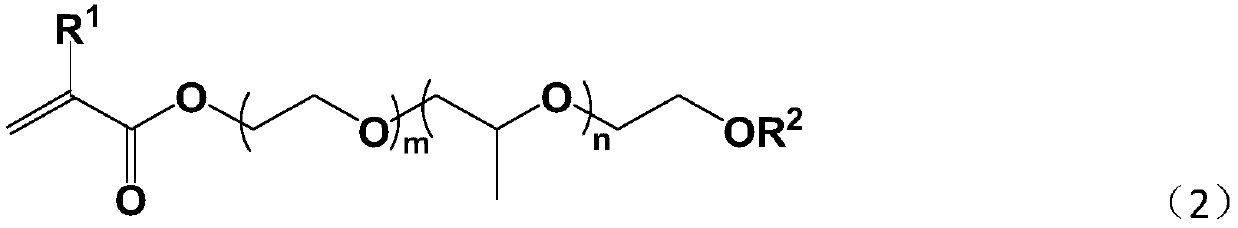

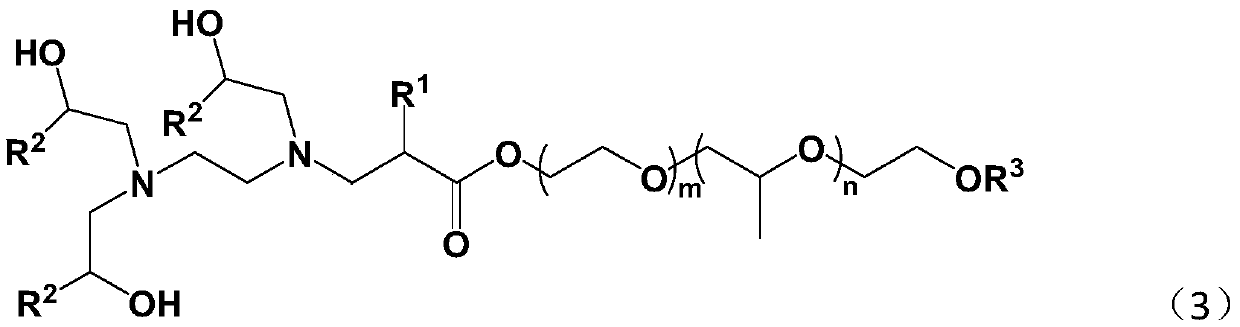

A cement grinding aid and grinding aid technology are applied in the preparation of grinding aids and the preparation of cement grinding aids, which can solve the problems of obvious difference in polymerization activity, decrease in polymerization efficiency, storage stability, etc., so as to avoid polymerization. Ineffective, optimized structure-activity relationship, strong structural adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 0.0 parts of unsaturated carboxylic acid ester monomer A-1, and 35.3 parts of diluent ethylene glycol dimethyl ether, add them into the reactor, and start the stirring and temperature control device. Weigh 17.9 parts of ethylenediamine, add it into the reactor at a certain rate under normal pressure, control the temperature in the reactor to 0°C, and continue the heat preservation reaction for 10.0 hours after the addition, to obtain a brownish yellow liquid, which is recorded as B- 1.

[0036] In the same way, the following amino polyether was prepared according to the same method for the synthesis of grinding aids.

[0037] Amino polyether B-2: 100.0 parts of unsaturated carboxylate monomer A-2, 41.6 parts of diluent ethylene glycol methyl ethyl ether, 3.9 parts of butanediamine, the reaction conditions are 10°C and normal pressure, and the heat preservation reaction is 8.0h. A brownish-yellow liquid was obtained, which was denoted as B-2.

[0038] Amino polye...

Embodiment 2

[0044] Weigh 39.3 parts of ethylene oxide, and gradually add it to the above-mentioned amino polyether monomer B-1 at a certain rate, control the reaction temperature to 30°C, and the reaction pressure is the pressure generated by the reaction system itself. After the feeding is completed, continue to keep warm After 7.0 hours of reaction, a brownish-yellow liquid was obtained. Add acetic acid to neutralize to pH=7, raise the temperature to 80-100°C, and under the pressure condition of -0.1MPa, distill the diluent in the reaction system under reduced pressure and recover it for reuse. Add water to dilute to 40%-50% solid content to obtain a dark brown-yellow finished grinding aid, which is designated as C-1.

Embodiment 3

[0046] Weigh 2.7 parts of ethylene oxide and 3.6 parts of propylene oxide, and gradually add them into the above-mentioned amino polyether monomer B-2 at a certain rate, control the reaction temperature to 40°C, and the reaction pressure to be the pressure generated by the reaction system itself. After the feed was finished, the heat preservation reaction was continued for 4.0 h to obtain a brownish-yellow liquid. Add acetic acid to neutralize to pH=7, raise the temperature to 80-100°C, and under the pressure condition of -0.1MPa, distill the diluent in the reaction system under reduced pressure and recover it for reuse. Add water to dilute to 40% to 50% solid content to obtain a dark brown-yellow finished grinding aid, which is recorded as C-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com