Preparation method of high-salt brine inhibitor

A technology of inhibitors and brine, applied in chemical instruments and methods, mechanical equipment, and other chemical processes, can solve problems such as blockage and scaling, achieve the effects of reducing costs, prolonging the feeding cycle, and preventing salt formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

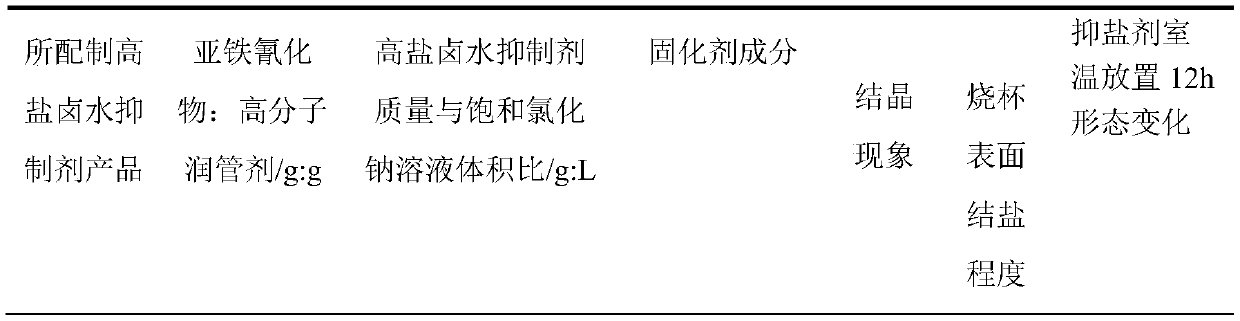

Embodiment 1

[0031] First add 1g of sodium ferrocyanide, 1g of sodium dodecylbenzenesulfonate and 5g of polymer tube lubricant into the crucible, stir and mix evenly, then pour 0.7g of bio-glue and stir and mix evenly again; take another test tube , used to prepare the curing agent, pour 8g white sugar, 5g water, 0.005g gelatin, 0.001g citric acid and 0.005g glass crisp into it, place it in an oil bath at 120°C while stirring and heat it, when the mixture appears fine and dense When the foam is in a molten state, quickly pour it into the above-mentioned crucible, stir it evenly with a glass cup, and place it at room temperature (25°C) to solidify for 2 hours. After the sample is fully dried, it is coarsely crushed to obtain a high-salt brine inhibitor.

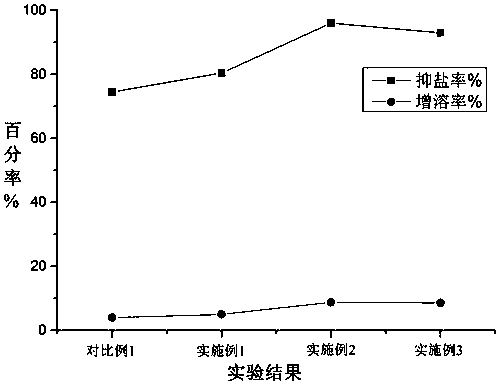

[0032] Weigh 250g of sodium chloride and 600mL of water into a 1L beaker, and stir at room temperature at 25°C until the sodium chloride is no longer dissolved. At this time, the solution reaches a supersaturated state. Take 400mL of the up...

Embodiment 2

[0034] First add 1g of sodium ferrocyanide, 1g of sodium dodecylbenzenesulfonate and 5g of polymer tube lubricant into the crucible, stir and mix evenly, then pour 0.7g of bio-glue and stir and mix evenly again; take another test tube , used to prepare the curing agent, pour 8g of sugar, 5g of water, 0.02g of gelatin, 0.012g of citric acid and 0.02g of glass brittle into it, place it in an oil bath at 120°C while stirring and heat it, when the mixture appears fine and dense When the foam is in a molten state, quickly pour it into the above-mentioned crucible, stir it evenly with a glass cup, and put it at room temperature (25°C) to solidify for 3 hours. After the sample is fully dried, it is coarsely crushed to obtain a high-salt brine inhibitor.

[0035] Weigh 250g of sodium chloride and 600mL of water into a 1L beaker, and stir at room temperature at 25°C until the sodium chloride is no longer dissolved. At this time, the solution reaches a supersaturated state. Take 400mL of t...

Embodiment 3

[0037] First add 1g of sodium ferrocyanide, 1g of sodium dodecylbenzenesulfonate and 5g of polymer tube lubricant into the crucible, stir and mix evenly, then pour 0.7g of bio-glue and stir and mix evenly again; take another test tube , for the preparation of curing agent, pour 8g of sugar and 5g of water into it, place it in an oil bath at 120°C while stirring and heat it, when the mixture appears fine and dense foam and is in a molten state, quickly pour it into the above crucible , stirred evenly with a glass cup, and cured at room temperature (25°C) for 3 hours. After the sample was fully dried, it was coarsely pulverized to obtain a high-salt brine inhibitor.

[0038] Weigh 250g of sodium chloride and 600mL of water into a 1L beaker, and stir at room temperature at 25°C until the sodium chloride is no longer dissolved. At this time, the solution reaches a supersaturated state. Take 400mL of the upper saturated sodium chloride solution and pour it into a 500mL beaker Take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com