A kind of preparation method of composite thermal control coating on alloy surface

A technology of thermal control coating and surface compounding, applied in the direction of surface reaction electrolytic coating, device for coating liquid on the surface, coating, etc., to achieve the effect of reducing cost, ensuring binding force, and improving binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

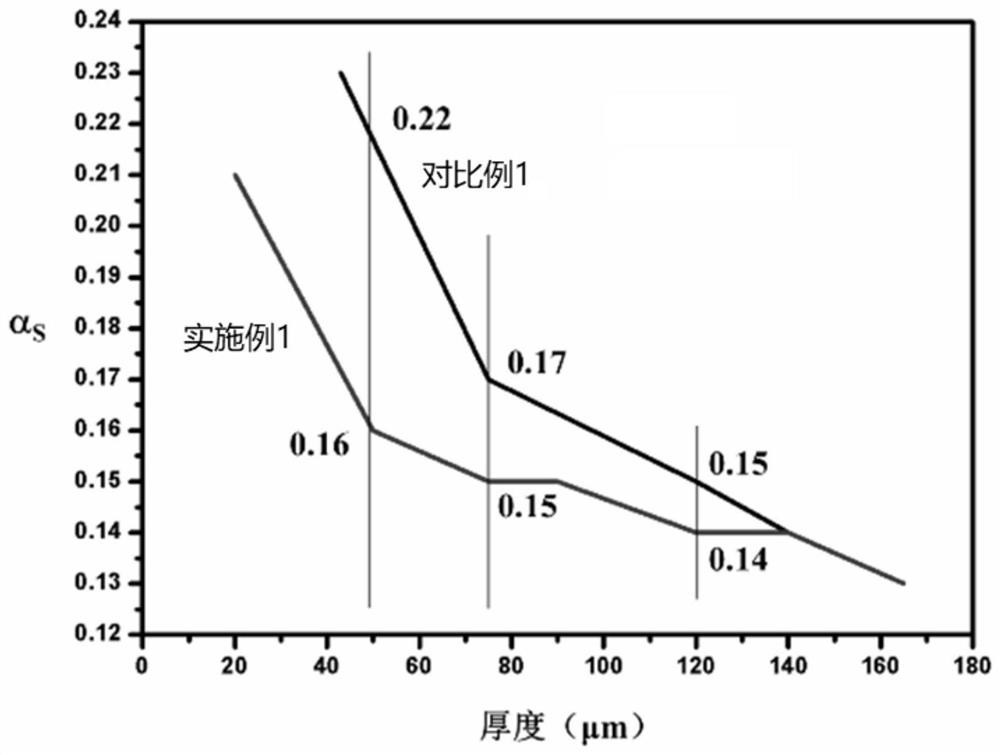

Image

Examples

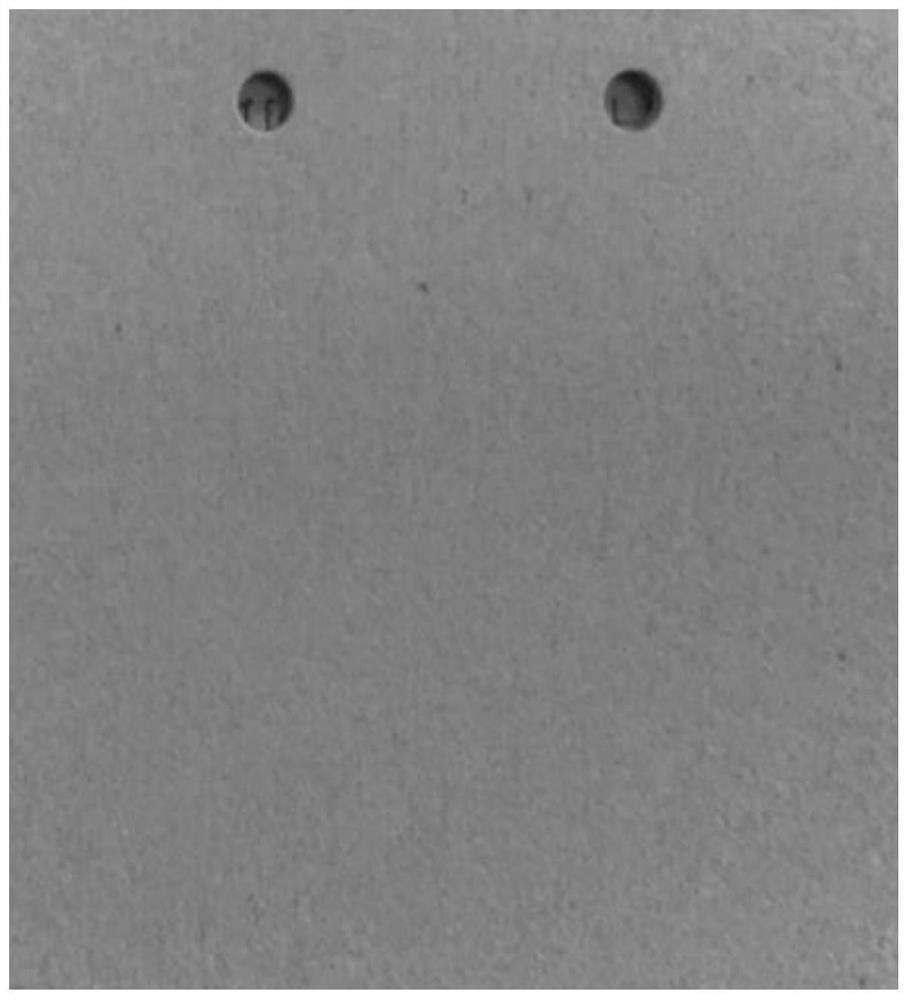

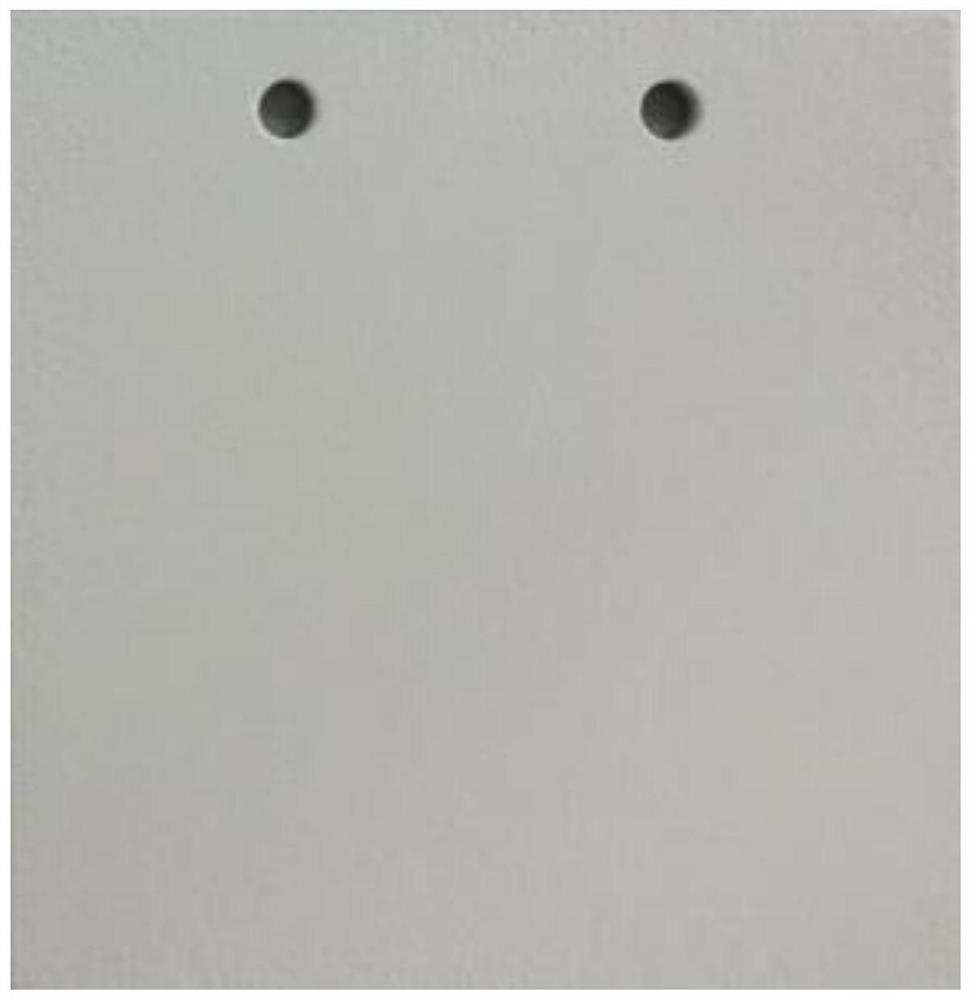

Embodiment 1

[0063] In this embodiment, a 2A12 aluminum alloy test piece with a size of 60×60×2mm is selected to prepare a composite thermal control coating on the surface of the alloy, including the following steps:

[0064] 1. Surface pretreatment of aluminum alloy parts:

[0065] It is mainly to remove the oil and oxide layer on the surface of the parts to expose the clean surface. The cleaning is mainly alkaline cleaning.

[0066] The aluminum alloy parts are immersed in a sodium hydroxide solution with a mass fraction of 1%-10% for 1-2 minutes, superwashed in deionized water for 1-10 minutes, rinsed with deionized water for 4-6 times, dehydrated and dried.

[0067] 2. Micro-arc oxidation:

[0068] Prepare a composite electrolyte system, in which disodium hydrogen phosphate is 60g / L, sodium phosphate 8g / L, potassium silicate 50g / L and sodium silicate 20g / L, and KOH is added to adjust the pH to 8-9, which will be processed in step 1 The final aluminum alloy parts are placed in the tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com