GaN-based completely-vertical Schottky varactor based on metal eave structure and preparation method thereof

A varactor and Schottky contact technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low output power and frequency multiplication conversion efficiency, low electron mobility, breakdown voltage and leakage current There is a large gap with the theoretical value, etc., to achieve the effect of eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a GaN-based complete vertical Schottky varactor based on a metal eaves structure, the preparation method comprising the steps of:

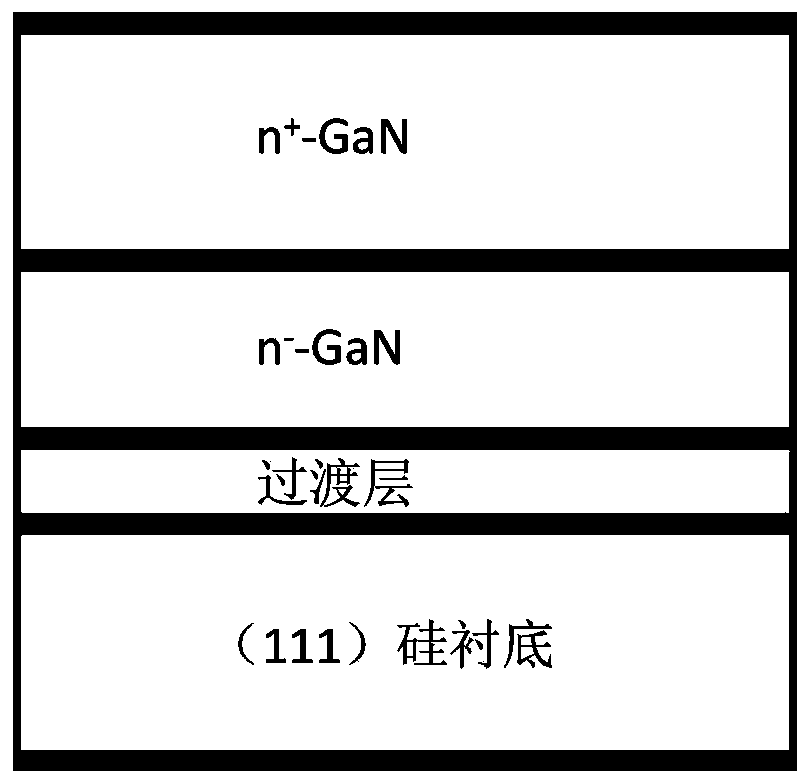

[0038] 1. If figure 1 As shown, lightly doped / heavily doped GaN epitaxial wafers with Si substrates with a diameter of 2 inches were selected. The epitaxial wafer structure from top to bottom is as follows: the doping concentration is greater than 5E18 / cm 3 The 3um~5um heavily doped layer (n+), the doping concentration is 3E16~2E17 / cm 3 300-500nm lightly doped layer (n-), transition layer (transition layer), Si substrate (Substrate);

[0039] 2. Ohmic metal evaporation: such as figure 2 shown, in n + -Using electron beam evaporation Ti / Al / Ni / Au on the GaN layer as the cathode (ohmic metal layer) of the device, followed by N 2 Rapid thermal annealing treatment at 850°C for 30s under ambient conditions;

[0040] 3. Evaporation of bonding metal Au: Evaporate another layer on the ohmic metal layer with a thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com