Processing method for reducing black circles of salted eggs

A processing method and a salted egg technology are applied in the processing field of reducing salted egg black circles, which can solve problems such as affecting appearance quality, affecting salted egg sales, etc., so as to reduce the phenomenon of salted egg black circles, reduce the phenomenon of salted egg black circles, The effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

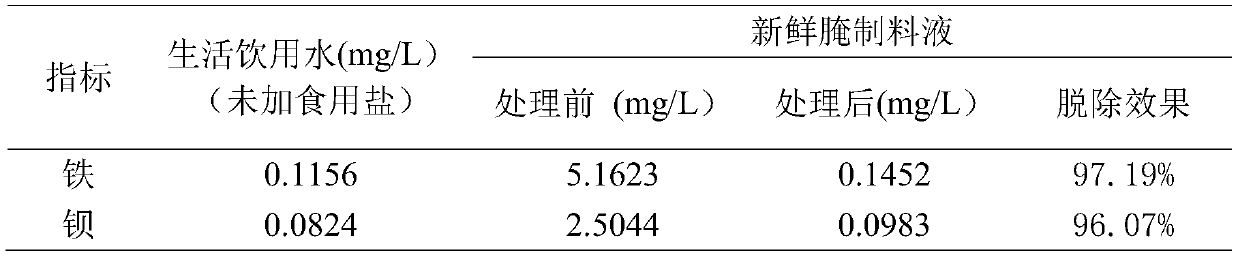

[0031] Preparation method of fresh marinade liquid

[0032] Step 1: adding 18% edible salt to the drinking water according to the mass ratio, dissolving and mixing to obtain a saline solution. The batches of edible salt used were tested by ICP-MS, and the iron content was 25.2436 mg / kg, and the barium content was 12.8225 mg / kg.

[0033] Step 2: The above-mentioned saline solution is processed through a circulation treatment system. Sequentially go through media filtration, activated carbon filtration, PP cotton security filtration, ultrafiltration, nanofiltration, post-adsorption and ultraviolet sterilizer sterilization treatment steps. Among them, the filter element of media filtration is made of acid quartz sand material with a diameter of 0.2-1.0mm; the filter element of activated carbon filter is made of fruit shell activated carbon material with a diameter of 0.1-0.5mm; the pressure of media filtration or activated carbon filtration treatment system is Between 0.6-1.1MP...

Embodiment 2

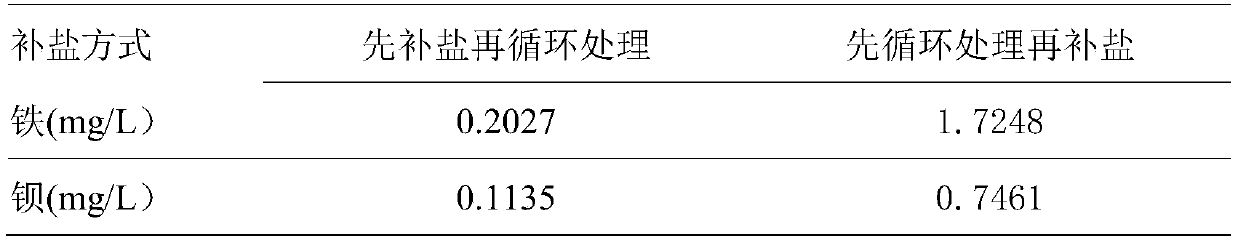

[0035] Preparation method of circulating marinade liquid

[0036] Step 1: recovering the used marinating liquid, adding edible salt, and preparing a marinating liquid with an edible salt content of 18%.

[0037]Step 2: The above marinating liquid is sequentially subjected to media filtration, activated carbon filtration, PP cotton security filtration, ultrafiltration, nanofiltration, post-adsorption and ultraviolet sterilizer sterilization treatment steps. Among them, the filter element of media filtration is made of acidic quartz sand material with a diameter of 0.2-1.0mm; the filter element of activated carbon filter is made of fruit shell activated carbon material with a diameter of 0.1-0.5mm; the pressure of media filtration or activated carbon filtration treatment system is Between 0.6-1.1MPa; the filter element of PP cotton security filter is made of 0.5-1μm polypropylene material; the filter element of ultrafiltration is made of PVC composite ultrafiltration membrane wi...

Embodiment 3

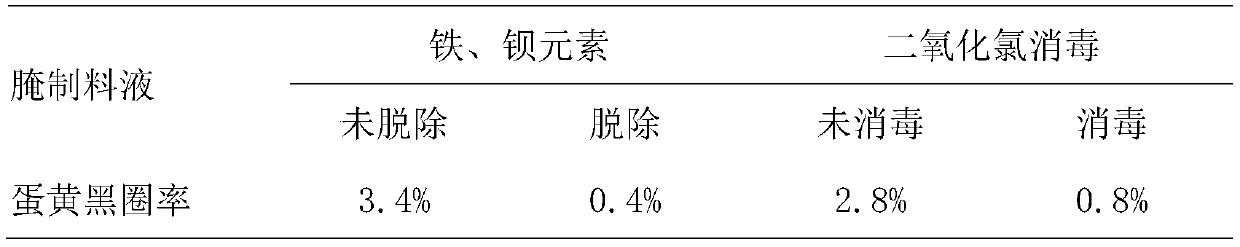

[0040] A processing method for reducing salted egg black circles, comprising the steps of:

[0041] (1) Cleaning pretreatment: wash fresh eggs with water containing 0.001-0.006% steady-state chlorine dioxide for 1-3 minutes, which can remove feathers, feces and other dirt on fresh eggs, remove damaged eggs, and reduce raw material microorganisms and foreign substances. background content of organic pollutants and then allowed to dry.

[0042] (2) salted egg pickling processing: put the fresh eggs processed in step (1) into the pickling facility, cover the surface with a hard plastic grid, add the fresh pickling liquid of Example 1 or the fresh pickling solution of Example 2 Circulate the marinating liquid, compact it with heavy objects, the marinating liquid is 2-10cm higher than the fresh eggs, and marinate for 30-35 days at 15-25°C until the salted eggs are matured. Among them, when fresh eggs are pickled by fresh pickling liquid, the effective concentration of chlorine dio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com