Nano tungsten phosphide/carbon or tungsten nitride/carbon composite material and preparation method thereof

A technology of carbon composite materials and tungsten phosphide, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of small effective specific surface area of materials and cumbersome process, and achieve safe and reliable production process , The process conditions are simple and easy to control, and the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a preparation method of nano-tungsten phosphide / carbon or tungsten nitride / carbon composite material, comprising the following steps:

[0030] Dissolving the tungsten source and the carbon source in a solvent to obtain a mixed solution; adjusting the pH value of the mixed solution to be alkaline;

[0031] The mixed solution is heated and evaporated to dryness to obtain a solid precursor;

[0032] Calcining the precursor under a protective atmosphere to obtain a solid powder;

[0033] Phosphating the solid powder with a phosphating agent under a protective atmosphere to obtain a tungsten phosphide / carbon composite material;

[0034] Alternatively, the solid powder is nitrided by a nitriding agent under a protective atmosphere to obtain a tungsten nitride / carbon composite material.

[0035] The above preparation method is explained in detail below.

[0036] Specifically, the used tungsten source and carbon source should be able to dissolve in the...

Embodiment 1

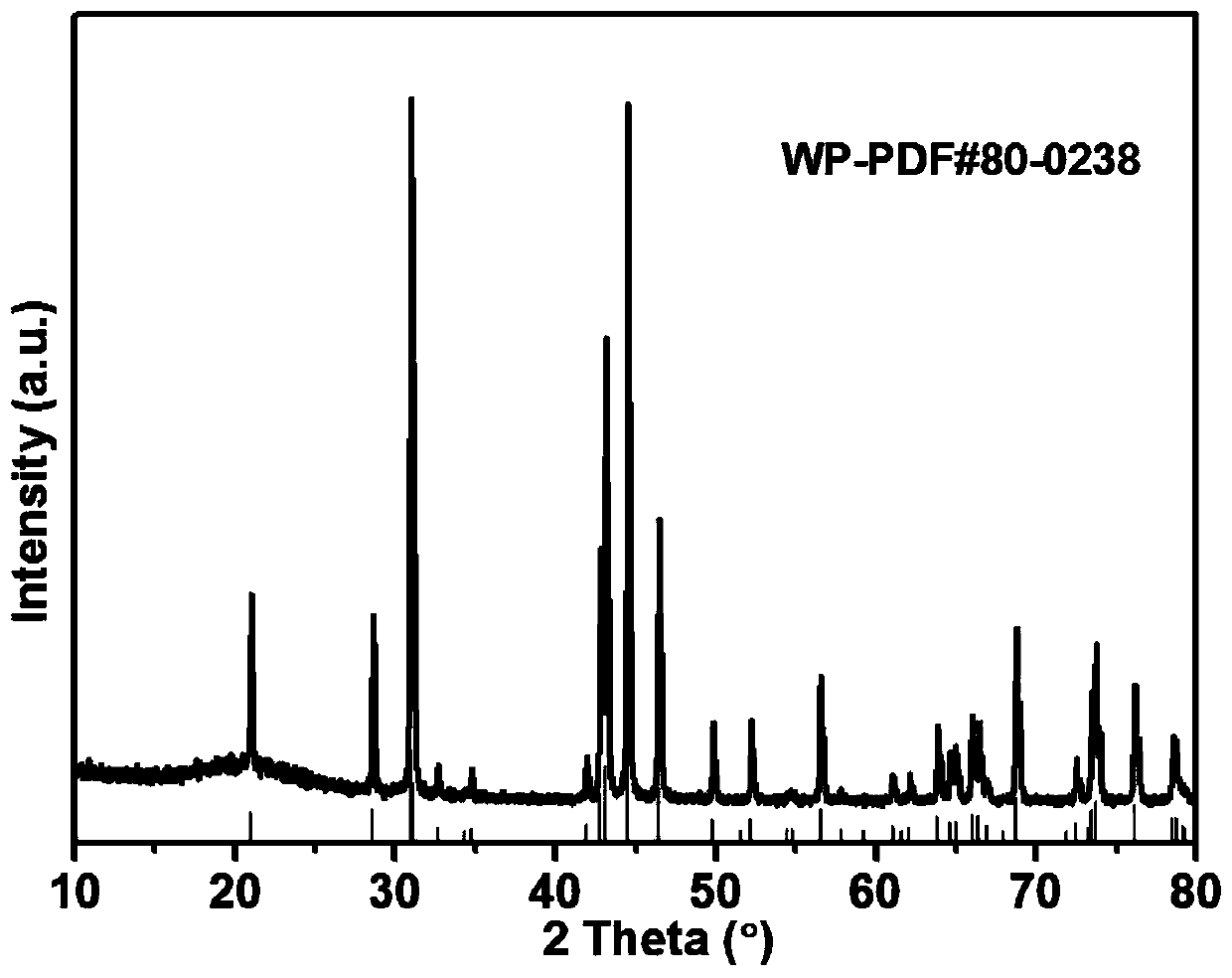

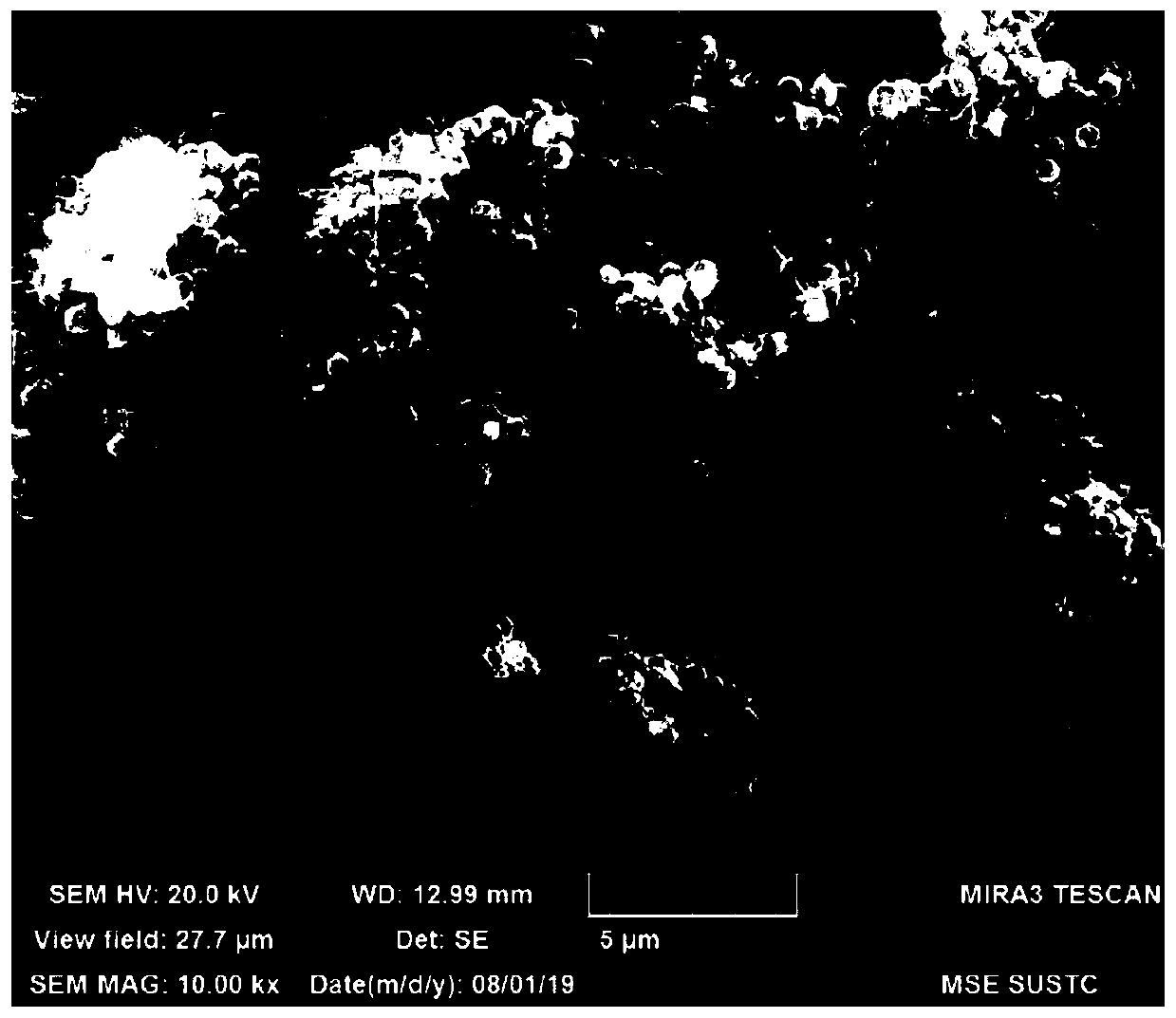

[0058] A preparation method of nano tungsten phosphide / carbon composite material, comprising the following steps:

[0059] (1). Dissolve 300mg of ammonium metatungstate in 70mL of deionized water, and stir until the ammonium metatungstate is completely dissolved, about 5 minutes;

[0060] (2). Add 300 mg of dopamine hydrochloride to the ammonium metatungstate solution obtained in step (1), and continue stirring until dopamine hydrochloride is completely dissolved for about 15 minutes to obtain the first mixed solution;

[0061] (3). Add 270 mL of absolute ethanol to the first mixed solution, stir until uniform, and add about 1 mL of ammonia water therein, stir evenly, the pH is 8.6, and continue to stir for about 12 hours to obtain the second mixed solution;

[0062] (4). Heat the second mixed solution in a water bath heating device to evaporate the solvent to obtain a precursor, then place the obtained precursor in a drying oven and dry at 60°C for about 8 hours to obtain the...

Embodiment 2

[0072] A preparation method of nanometer tungsten nitride / carbon composite material, comprising the following steps:

[0073] (1). Dissolve 300mg of ammonium metatungstate in 70mL of deionized water, and stir until the ammonium metatungstate is completely dissolved, about 5 minutes;

[0074] (2). Add 300 mg of dopamine hydrochloride to the ammonium metatungstate solution obtained in step (1), and continue stirring until dopamine hydrochloride is completely dissolved for about 15 minutes to obtain the first mixed solution;

[0075] (3). Add 270 mL of absolute ethanol to the first mixed solution, stir until uniform, and add about 1 mL of ammonia water therein, stir evenly, and continue to stir for about 12 hours to obtain a second mixed solution;

[0076] (4). Heat the second mixed solution in a water bath heating device to evaporate the solvent to obtain a precursor, then place the obtained precursor in a drying oven and dry at 60°C for about 8 hours to obtain the first solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com