Conical spiral bubble conveying device and preparing method thereof

A technology of bubbles and spirals, which is applied in the field of bubble transportation devices and its preparation, can solve problems such as pipeline corrosion and shorten equipment life, and achieve the effect of eliminating corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

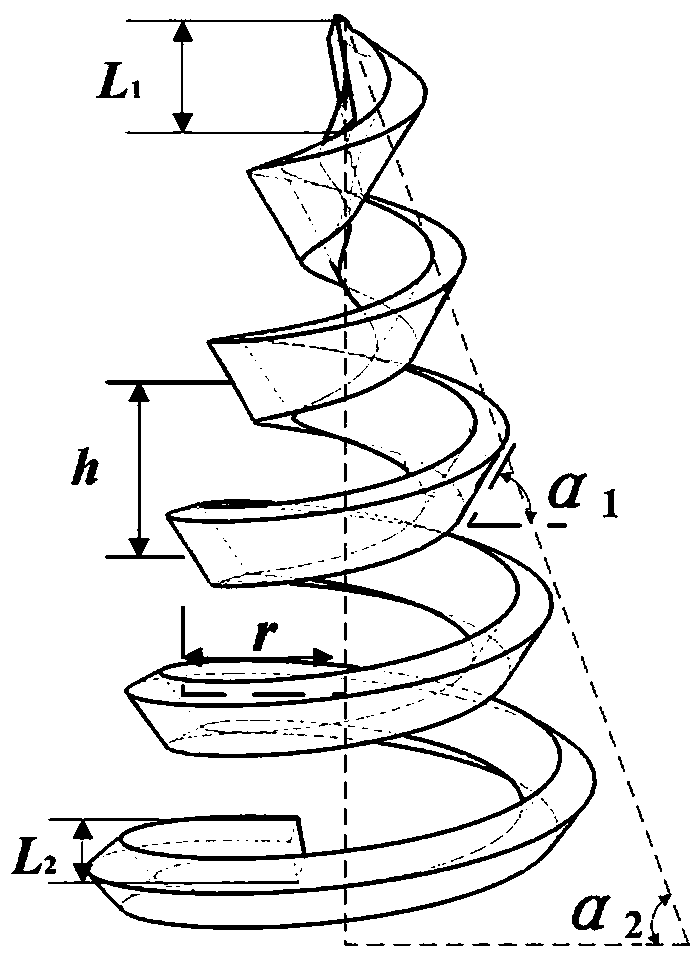

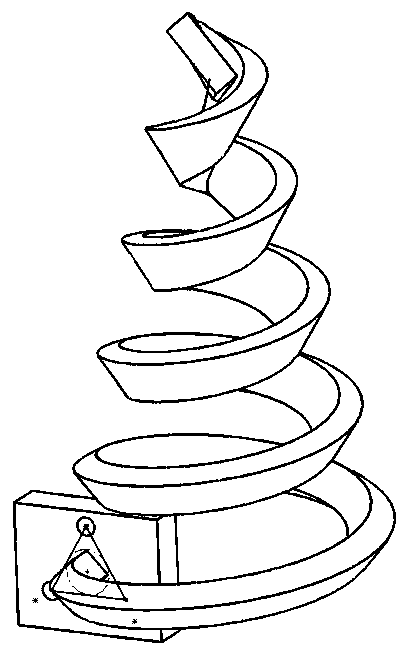

[0035] Referring to the accompanying drawings, the cone-helix air bubble transport device includes a cone-helicoid, and the structure of the cone-helicoid in the three-dimensional space coordinate system is as follows:

[0036] The inclination angle to the Z axis is α 1 , the side length is L 2 A regular quadrilateral, from the bottom along the pitch h, the taper is The spiral line of the regular quadrilateral gradually increases upwards, and the two vertically opposite sides of the regular quadrilateral increase linearly to L 1 , the base radius of the helix is r, and the number of rotations is n.

[0037] Use 3D software to model, and make the bionic cone helix take the following structural parameters: α 1 =45°, α 2 =30°, L 1 =3 mm, L 2 =1mm, h =5 mm, n =7, r =10 mm; 3D printing technology can be used to prepare three-dimensional cone and helix.

[0038] The cone-screw device of the present invention is fixed on the base, and then the base is installed at th...

Embodiment 2

[0040] With reference to the accompanying drawings, this example adopts the following steps on the basis of the cone screw device prepared in embodiment one:

[0041] Step 2, preparing rough micro-nano structure: using femtosecond laser to scan the surface of the pyramidal helicoid to obtain rough micro-structure;

[0042] Step 3, prepare super-hydrophobic substrate: use a brush to dip an appropriate amount of super-hydrophobic solution to evenly coat the inner surface of the cone spirochetes, and dry the sample on the surface of the drying table adjusted to 60 °C for 15 minutes to ensure that the solvent is completely Volatilize, then repeat dipping, coating, and drying five times;

[0043] Step 4: Add HFE7100 lubricant dropwise, blow the surface with a hair dryer to remove excess lubricant, and form a lubricating film on the surface of the substrate.

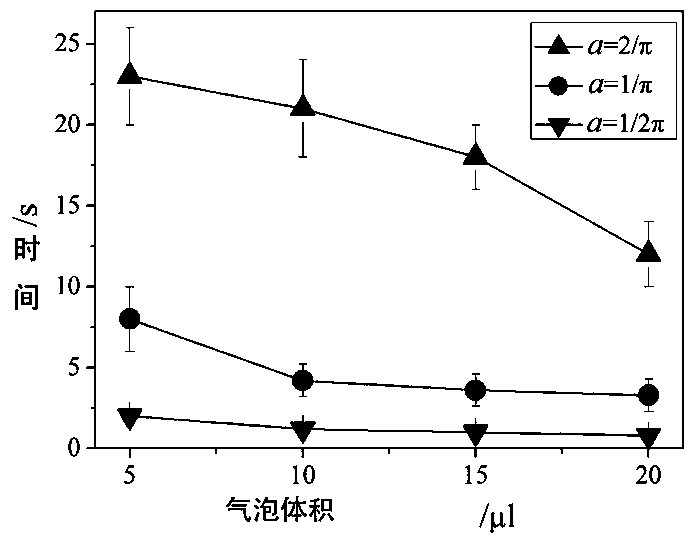

[0044] The cone spirochete described in this example can be used in a liquid environment due to the superhydrophobic treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com