Preparation method of eutectic, reinforced and toughened silicon nitride ceramic

A technology of silicon nitride ceramics and tough silicon nitride, which is applied in the preparation of high-performance silicon nitride ceramics and the field of silicon nitride ceramics with α/β eutectic structure, which can solve the problems of limiting the application and promotion of silicon nitride , to improve performance, relieve stress concentration, and improve brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Mixing: Mix the dried ceramic raw materials evenly in proportion, and pass through a 60-mesh sieve. The ceramic raw materials are composed of the following components:

[0049] Silicon nitride powder: 90%;

[0050] Sintering aid: 9%;

[0051] Phase change inhibitor: 1%;

[0052] The sintering aid consists of the following components:

[0053] Al 2 o 3 : 60%;

[0054] Y 2 o 3 : 40%;

[0055] (2) Grinding: Put the powder to be mixed in a sand mill, add powder and ethanol according to powder: ethanol = 1:2, set the sand mill speed to 3000r / min, and sand mill for 2 hours.

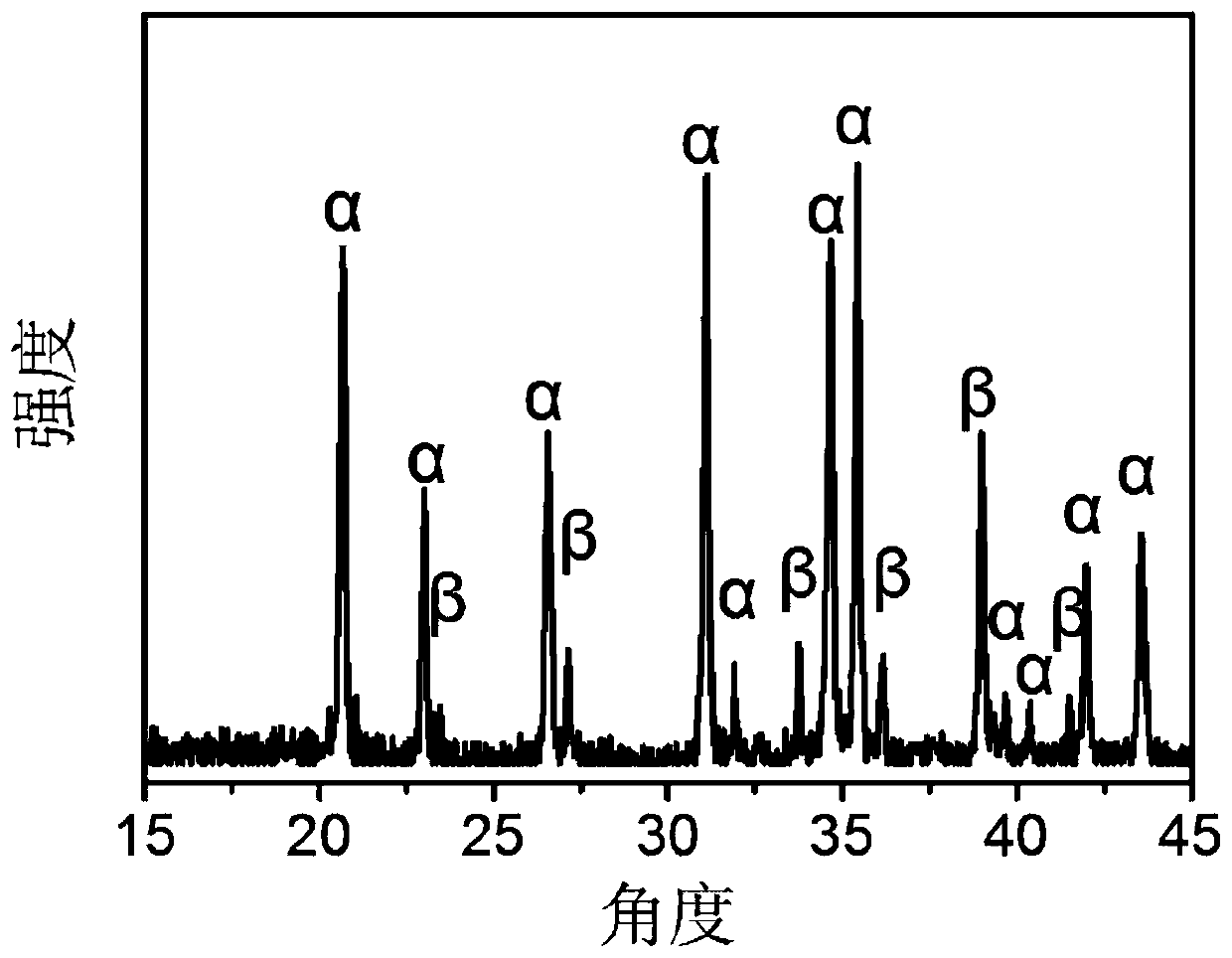

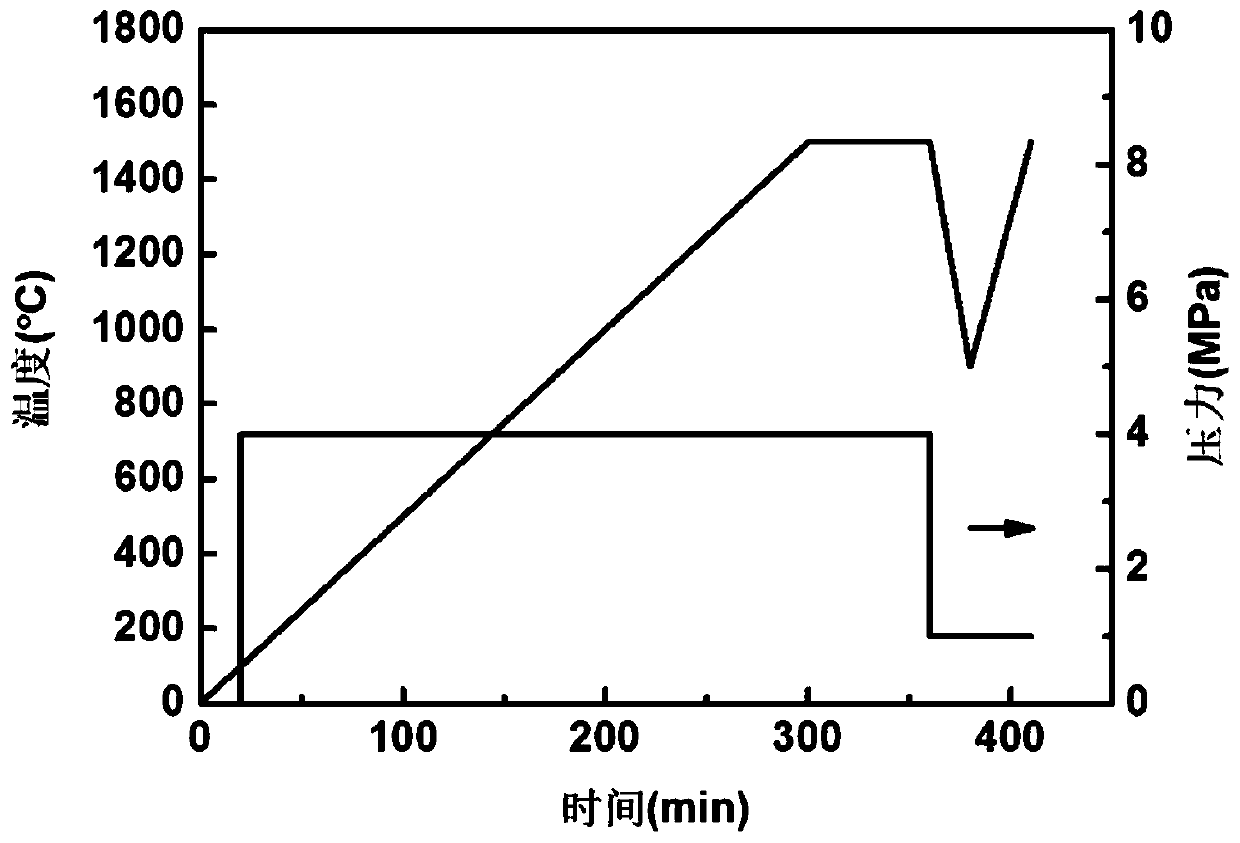

[0056] (3) Sintering: Put the powder into the SPS mold and put the mold into the SPS device. After vacuuming, heat up to 1500°C at a speed of 150°C / min, keep it under 10MPa pressure for 5min, stop heating and cool with the furnace to room temperature. After taking out the sample, a primary sintered body was obtained, the relative density of the obtained primary sintered body was 99.1%, and th...

Embodiment 2

[0059] (1) Mixing: Mix the dried ceramic raw materials in proportion and pass through a 100-mesh sieve. The ceramic raw materials are composed of the following components:

[0060] Silicon nitride powder: 80%;

[0061] Sintering aid: 15%;

[0062] Phase change inhibitor: 5%;

[0063] The sintering aid consists of the following components:

[0064] MgO: 40%;

[0065] Y2O3: 40%;

[0066] SiO2: 20%

[0067] (2) Grinding: Put the powder to be mixed in a ball mill, add powder and ethanol according to powder: ethanol = 1:2, set the sand mill speed to 300r / min, and ball mill for 10h.

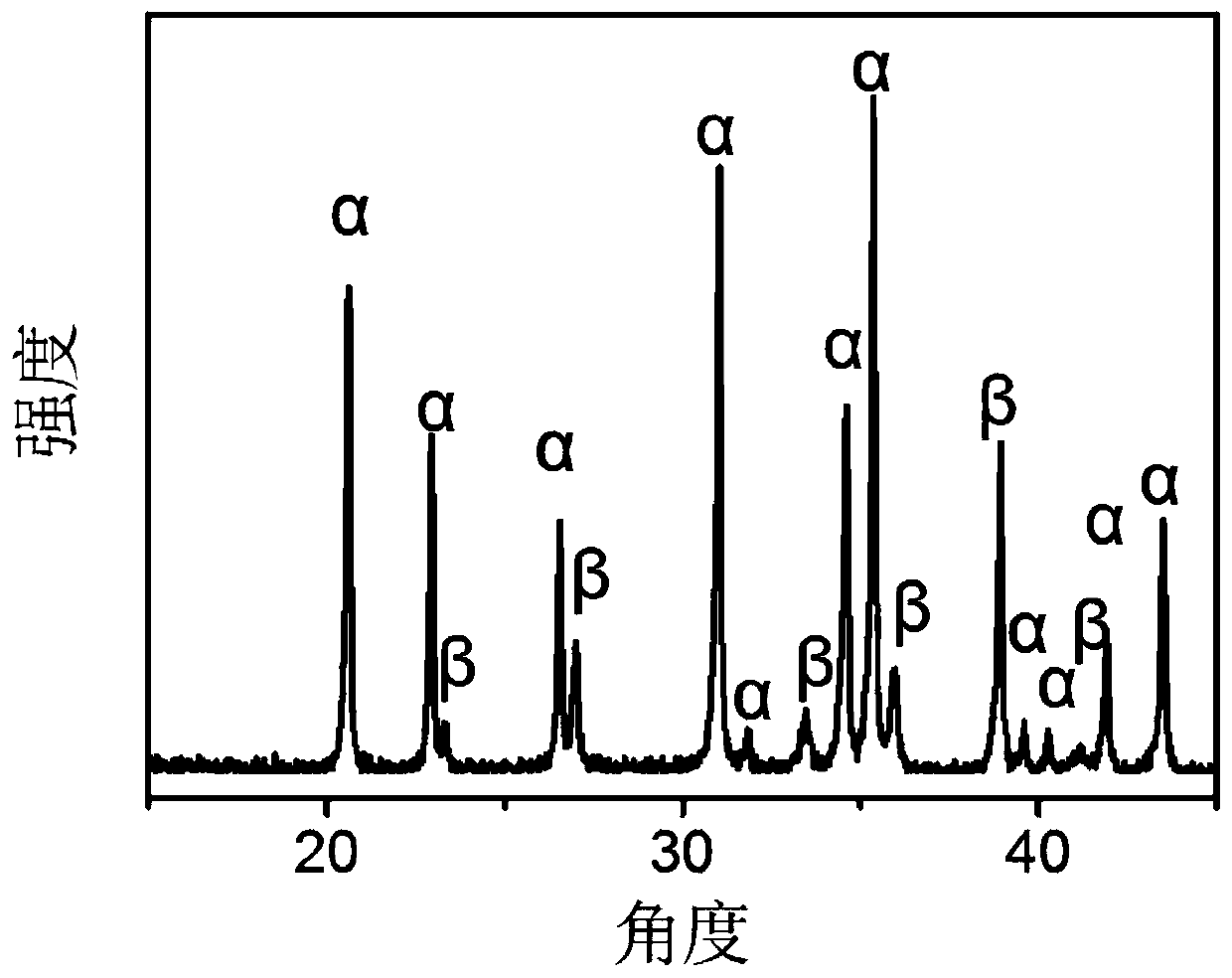

[0068] (3) Sintering: Put the powder into the SPS mold and put the mold into the SPS device. After vacuuming, heat up to 1500°C at a speed of 150°C / min, keep it warm for 5min under a pressure of 50MPa, stop heating and follow the furnace Cool to room temperature. After taking out the sample, a primary sintered body was obtained, the relative density of the obtained primary sintered body was 99.3...

Embodiment 3

[0071] (1) Mixing: Mix the dried ceramic raw materials in proportion and pass through a 200 mesh sieve. The ceramic raw materials are composed of the following components:

[0072] Silicon nitride powder: 70%;

[0073] Sintering aid: 20%;

[0074] Phase change inhibitor: 10%;

[0075] The sintering aid consists of the following components:

[0076] La 2 o 3 : 40%;

[0077] MgSiN 2 : 40%;

[0078] ZrO 2 : 20%

[0079] (2) Grinding: Put the powder to be mixed in a stirring mill, add powder and ethanol according to powder: water = 1:3, set the sand mill speed to 500r / min, and grind for 5 hours.

[0080] (3) Sintering: Put the powder into the SPS mold and then put the mold into the SPS device. After vacuuming, heat up to 1500°C at a speed of 200°C / min, keep it under 100MPa pressure for 5min, stop heating and follow the furnace Cool to room temperature. After taking out the sample, a primary sintered body was obtained, the relative density of the obtained primary sintere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com